AI in Manufacturing: Benefits, Uses, and Future Trends

Manish Kumawat

Last Updated on: 03 September 2025

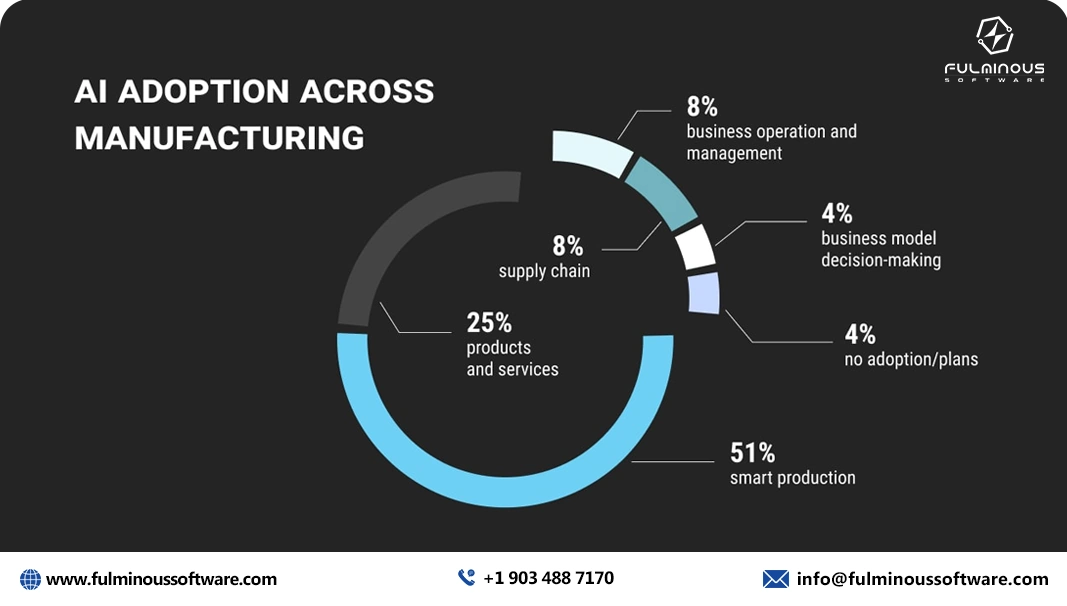

Projections show that AI in the manufacturing industry will reach $68.3 billion+ by 2030, and those businesses that began to use Artificial Intelligence in manufacturing have been experiencing a revenue increase of 6% to 10%. What about your manufacturing business?

The absence of AI in manufacturing business means you are far behind in the competition. At the same time, you might have been feeling difficulties in fulfilling users' demand, predicting machine maintenance, managing energy usage, and doing the same manual tasks several times. All these are the result of not taking advantage of AI in manufacturing.

If you have not used AI in manufacturing till now, it's time to know more about AI in manufacturing. No matter what kind of manufacturing business you are running, AI can transform your whole business and bring plenty of benefits. Whether you need AI for production planning or AI in smart manufacturing, this guide is ideal for you.

Table of Contents

- 1. Challenges Faced by Manufacturing Businesses Without AI

- 2. Benefits of AI in Manufacturing

- 3. AI Applications in Manufacturing and Its Benefits

- 4. Types of AI Technologies Useful for Manufacturing

- 5. AI Technologies Useful for All Manufacturing Businesses

- 6. AI in Manufacturing: Future Developments

- 7. AI Agents in Manufacturing

- 8. Cost Breakdown of AI Implementation in Manufacturing

- 9. Why Choose Fulminous Software for Manufacturing AI Services?

- 10. Advanced AI in Manufacturing Services from Fulminous Software

- 11. Get Manufacturing AI Services in 3 Simple Steps

- 12. Conclusion

- 13. FAQs

Challenges Faced by Manufacturing Businesses Without AI

When you deeply study the success of top manufacturing companies, you can notice the impact of AI in the manufacturing business. When businesses follow the traditional way of manufacturing and ignore the usage of AI, it can result in several challenges.

- Are you having trouble in meeting customer demand and planning production?

- Do you get regular complaints on product defects?

- Is your equipment stopping working often without warning?

- Are manual tasks slowing down your production and causing mistakes?

- Is it hard to manage your production schedule?

- Do you have a lot of data but no clear way to use it?

- Are you struggling to deal with supply chain issues?

- Do you notice your product quality isn’t always the same?

- Is it hard to customize your products for different customers?

- Are you spending huge money on manual tasks and regular maintenance?

If you are facing any of the above challenges, it's time to add AI in your manufacturing business. Nowadays, using AI in manufacturing is a necessity rather than a fancy trend. It's just like getting overall help in all the activities of manufacturing business, including designing products to making wise decisions.

Benefits of AI in Manufacturing

Impact of AI in manufacturing industry is more than what we expect.

Overall Business Growth

Overall business growth is the major benefit of AI in manufacturing business, which you can experience by adding AI features to your business.

Enhanced Quality Control

As AI is capable of knowing exactly what exactly your users demand, you get recommendations from AI in manufacturing to bring better quality to your overall business.

Predictive Maintenance Efficiency

AI predicts possible failures of your manufacturing machines so that you can do the maintenance before they stop and cause large downtime.

Optimized Production Planning

AI in manufacturing helps plan daily tasks and resource use, so that your factories produce more in less time without delays.

Real‑Time Demand Forecasting

AI is capable of analyzing market trends and past data to predict the best ways to achieve success in your manufacturing business venture.

Reduced Operational Costs

Use of ai in manufacturing cuts waste, improves machine use, and reduces labor for repetitive tasks, which helps companies save money every month.

Improved Energy Management

AI is the best tool to save energy in your manufacturing process, which can also reflect in your overall manufacturing business expenses.

Faster Product Innovation

AI analyzes customer needs and design data so that you can manufacture more useful products for your users and become the leader of your industry.

Smarter Supply Chain Decisions

Use of ai in manufacturing helps in delivering your product to whom you want to sell with accuracy, no delays, and smoothness monitoring

AI Applications in Manufacturing and Its Benefits

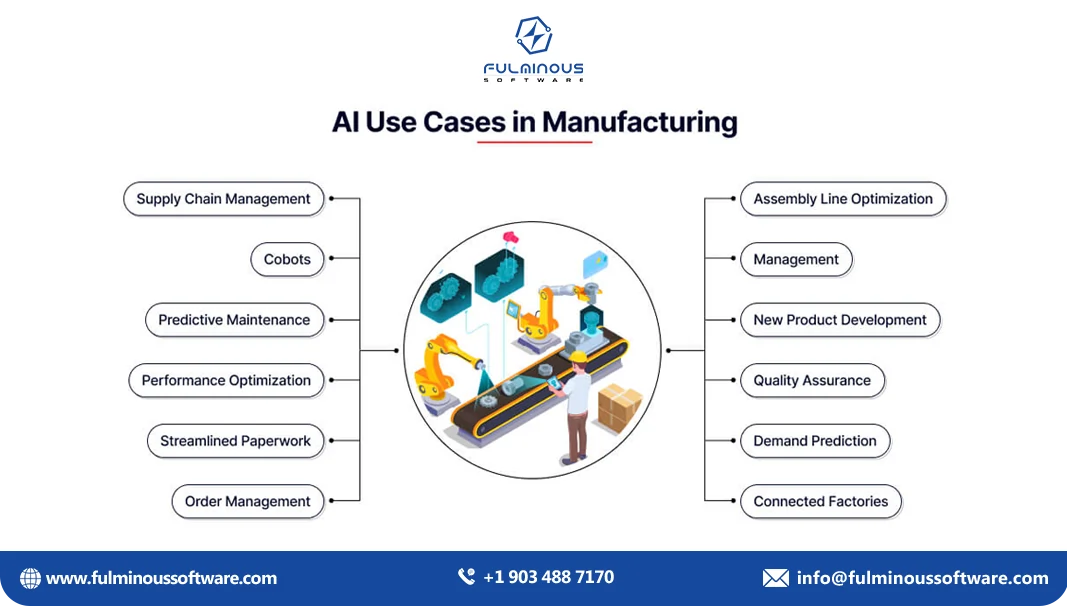

See how is ai used in manufacturing:

|

Predictive Maintenance Tools Avoid downtime, minimize costs. |

Vision-Based Quality Inspection Detect defects in real time. |

|

Supply-Chain Optimization Route and inventory intelligence. |

Robotic Process Automation Automate repetitive line tasks. |

|

Energy Optimization Systems Cut waste and emissions. |

Telematics & Analytics Data-driven performance tracking. |

|

Worker Safety Monitoring Hazard detection via vision. |

Demand Forecasting Engines Match production with market trends. |

|

Digital Twins Simulate real-time factory operations. |

AI-Powered CNC Optimization Enhance precision and reduce waste. |

|

Automated Production Scheduling Balance workloads. |

Smart Inventory Management Track stock levels. |

Types of AI Technologies Useful for Manufacturing

When you get AI services for manufacturing from leading ai development companies like Fulminous Software, you can access various kinds of AI technologies.

Predictive Maintenance

Integration of predictive maintenance to your manufacturing businesses is useful to predict failures, reduce downtime, and extend equipment lifespan.

Computer Vision & Quality Control

Adding automated visual inspection systems can help to detect defects, inconsistencies, or deviations in your manufacturing process and machines.

Robotics & Automation

AI-powered robots can handle repetitive tasks, assembly, and material handling so that you can bring perfect products in a short period of time.

Demand Forecasting & Inventory Optimization

You can integrate machine learning models into your manufacturing business that forecast demand patterns, optimize stock levels, and reduce waste.

Digital Twins & Simulation

Adding AI-driven digital replicas of manufacturing systems is beneficial to simulate operations, predict outcomes, and support decision-making for your business.

Natural Language Processing (NLP)

You can add NLP features to your manufacturing business that enable voice-activated systems, smart documentation, and chatbot interfaces for overall support in manufacturing operations.

AI Technologies Useful for All Manufacturing Businesses

No matter what you manufacture or the size of your manufacturing business, AI can transform your business and help you in achieving the eah goals. AI is useful for all the following manufacturing businesses.

| Automotive & Machinery | Electronics & Semiconductors | Food & Beverage |

| Pharmaceuticals | Consumer Goods | High-Tech Assembly |

| Energy & Utilities | Aerospace & Defense | Heavy Equipment |

| Textiles & Apparel | Furniture & Wood Products | Construction Materials (Cement, Bricks, Glass) |

| Paper & Packaging | Metals & Mining | Plastics & Chemicals |

AI in Manufacturing: Future Developments

Now it self you can notice the huge impact of AI in the manufacturing business. But in the coming days, you are going to witness more amazing influences of AI in manufacturing and ai in trasportation.

Fully Connected Smart Factories

Complete smart factory integration systems that reduce human efforts are expected in the coming days..

Intelligent Defect and Quality Systems

Real-time AI defect detection solutions and quality maintenance solutions are going to become more accurate in the future.

Green Production via AI‑Driven Efficiency

Implementing greener manufacturing operations is another trend we expect in the near future.

Integrated Production‑Logistics Sensor Networks

Integration of smart sensors for factory-wide coordination is going to transform the whole logistics process in manufacturing business.

Continuously Learning Factory AI Agents

Learning AI agents for better decisions is expected to become a major part of manufacturing industries in the future.

AI Agents in Manufacturing

AI agents in manufacturing are equivalent to getting guidance and assistance from many experts in each task. The major AI agents in manufacturing businesses are:

| Predictive Maintenance Agent | Quality Inspection Agent | Production Scheduling Agent |

| Inventory Management Agent | Supply Chain Optimization Agent | Energy Efficiency Agent |

| Robotic Process Control Agent | Defect Detection Agent | Real-Time Monitoring Agent |

With the assistance of a leading AI development company like Fulminous Software, you can easily develop ai agents for your manufacturing business.

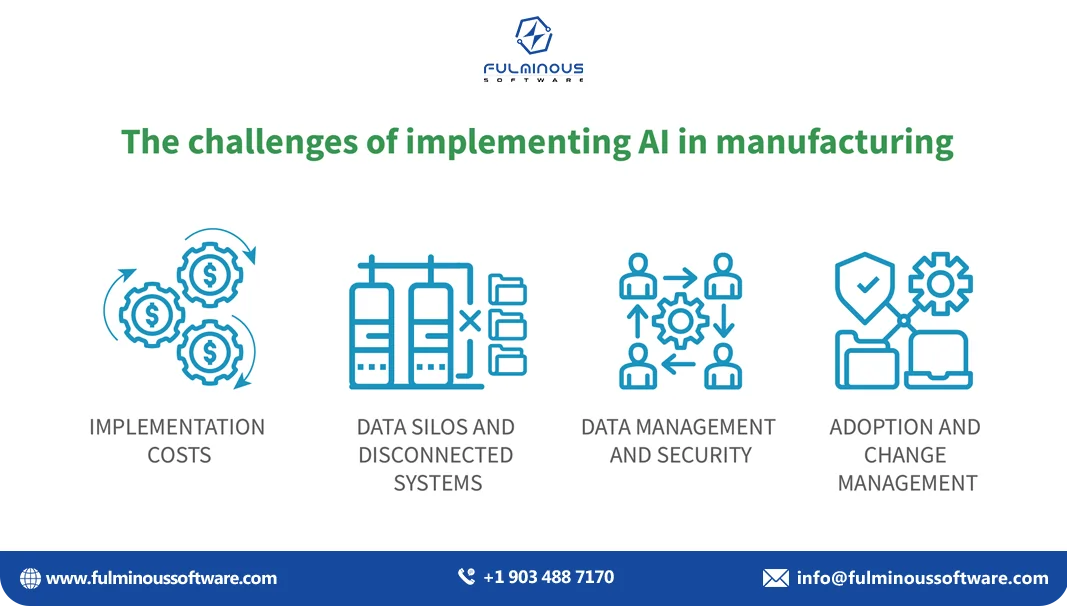

Cost Breakdown of AI Implementation in Manufacturing

| Component | Small Business | Mid-Sized Business | Large Enterprise |

|---|---|---|---|

| AI Consultation & Strategy | $5,000 – $15,000 | $15,000 – $40,000 | $50,000+ |

| AI Software & Tools | $10,000 – $30,000 | $30,000 – $100,000 | $150,000+ |

| Data Integration & Preparation | $8,000 – $25,000 | $25,000 – $80,000 | $100,000+ |

| AI Model Development/Training | $15,000 – $50,000 | $50,000 – $120,000 | $200,000+ |

| Hardware (IoT, Sensors, GPUs) | $10,000 – $35,000 | $40,000 – $150,000 | $250,000+ |

| Pilot Testing & Deployment | $10,000 – $30,000 | $30,000 – $90,000 | $120,000+ |

| Maintenance & Support (Yearly) | $5,000 – $15,000 | $20,000 – $50,000 | $100,000+ |

Estimated Total Cost of AI in Manufacturing

| Business Size | Estimated Total Cost |

|---|---|

| Small Business | $50,000 – $150,000 |

| Mid-Sized Business | $150,000 – $500,000 |

| Large Enterprise | $500,000 – $1.2M+ |

Why Choose Fulminous Software for Manufacturing AI Services?

As a top AI development company, Fulminous Software has a bunch of top AI experts who know all the trends in the manufacturing industry. This combination of AI proficiency and manufacturing industry knowledge is the major reason that invites you to hire Fulminous Software, the best AI in manufacturing development company. You can access all the benefits of AI in manufacturing by hiring Fulminous Software, while also exploring the advantages of AI in transportation to streamline logistics and supply chains. Also, Use of AI chatbots in healthcare to get an instant report about your health insights by past report analysis.

Cost‑Effective

Fulminous Software delivers AI solutions for manufacturing businesses at a more affordable rate compared to other companies.

Demonstrated Success

Fulminous Software has proven project experience in using AI in manufacturing businesses and bringing the best solutions.

Custom Systems

We create AI systems after evaluating the specific needs of your manufacturing business, which means a unique AI solution for your manufacturing business.

Long‑Term Model Tuning and Support

Our team offers long-term tuning and support of what we implement to your manufacturing business, so no chance of failure in the long term.

Operator‑Centric Designs

Fulminous Software designs AI tools that are easy for factory staff to use and that simplify their tasks to bring maximum productivity.

Expert AI in Manufacturing

Fulminous Software is a team of excellent AI experts who can easily integrate AI with your machines, software, and workflows.

Robust Security and Compliance Adherence

We follow strong security practices and meet industry rules like GDPR or HIPAA, keeping your factory’s data and systems safe.

Roadmaps for Full Deployment

Fulminous Software guides you step-by-step on AI integration to your manufacturing business with a clear plan.

Advanced AI in Manufacturing Services from Fulminous Software

Fulminous Software, the leading AI in manufacturing development company, offers complete AI solutions for manufacturing businesses.

AI Consultation for Manufacturing

Fulminous Software offers expert advice and roadmap preparation, helping you to get proper strategies for implementing AI solutions in the manufacturing business.

Manufacturing AI Management Solutions

Our AI solutions in manufacturing build AI systems that manage workflows, improve efficiency, track performance, and make smarter decisions in your entire manufacturing operations.

AI‑Driven Logistics & Supply Chain

Fulminous Software helps to add AI features that plan routes, manage inventory, and predict delays for timely movement of materials and finished products.

Custom AI Applications in Manufacturing

Fulminous Software builds advanced custom AI applications in manufacturing businesses that help to meet unique factory needs, enhancing productivity and business-specific problem-solving.

AI for Smart Manufacturing Automation

Our AI solutions in manufacturing use AI to automate machines, monitor performance, and reduce errors, making your manufacturing process smarter.

Generative AI in Manufacturing

Fulminous Software adds Generative AI that helps in creating multiple product or component design options based on proper data analyses.

Manufacturing Data Analytics & Insights

Fulminous Software helps manufacturing businesses use AI in analyzing large sets of production data to find trends and make perfect decision-making across departments.

Plant Infrastructure Planning with AI

We add AI for production planning that helps design better factory layouts, resource usage, and workflow systems, ensuring space, energy, and time.

Real‑Time Monitoring & Adaptive Control

Our AI monitors machines and processes live, making real-time changes to optimize performance, avoid breakdowns, and reduce human intervention.

AI Maintenance & Lifecycle Support

Fulminous Software offers AI maintenance and lifecycle support for manufacturing businesses to maintain their business tasks more accurately and efficiently.

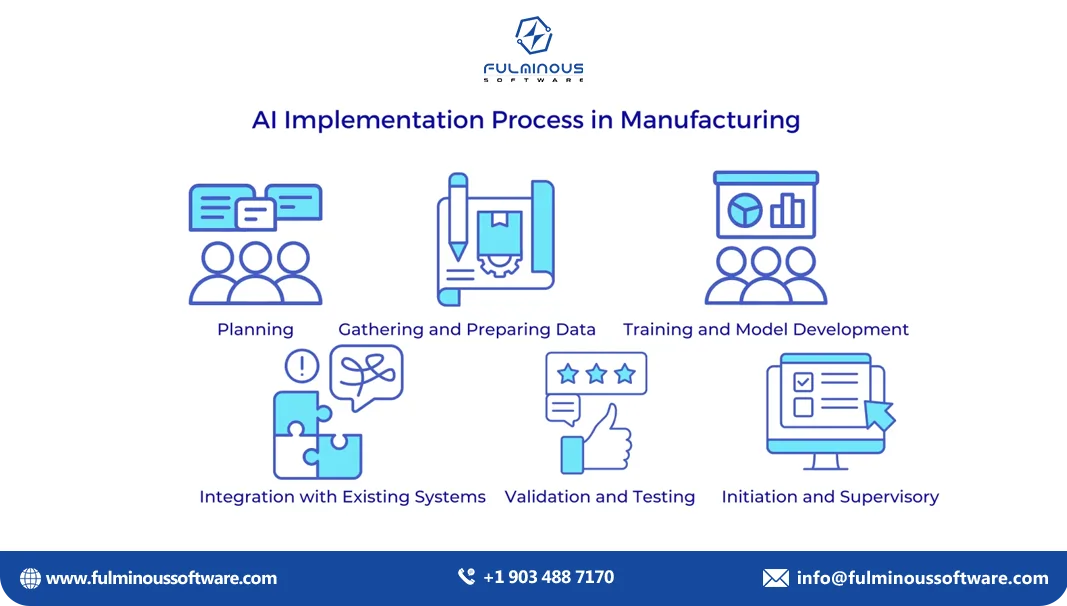

Get Manufacturing AI Services in 3 Simple Steps

|

Step 1 Share your requirements |

Step 2 Get a free Manufacturing AI project estimate |

Step 3 Kick-start your Manufacturing AI with our team |

Conclusion

In short, wise businesses are grabbing the benefits of AI in manufacturing. AI applications in manufacturing are getting advanced day by day. You can also get into it by getting the best AI solutions in manufacturing. Also use of artificial intelligence in the logistics industry can boost productivity and efficiency

The highlight of AI in manufacturing services of Fulminous Software is its cost efficiency, which makes it accessible to all sizes of business. Our 20+ AI specialists help you to upgrade your manufacturing business with advanced AI applications. Our AI solutions in manufacturing guarantee an overall transformation for your manufacturing business that takes your business to a more profitable stage. Collaborate with us and get the best AI in manufacturing services.

FAQs

Q1. How much does AI in manufacturing cost?

Ranges from $10,000 for basic systems to $150,000+ for full-scale smart factory deployments.

Q2. How long does it take to implement AI in manufacturing?

Pilot systems: 4–8 weeks; enterprise solutions: 3–6 months.

Q3. What are the benefits of AI in manufacturing?

Better quality control, uptime, productivity, insights, sustainability, and cost efficiency.

Q4. How is AI being used in production?

For production planning, maintenance, quality inspection, supply-chain optimization, safety, and energy efficiency.

Q5. How does AI improve productivity in manufacturing?

By automating processes, reducing downtime, forecasting demand, and optimizing operations.

Q6. Can you integrate AI with existing systems?

Yes, fully integrates with MES, ERP, IoT platforms, and plant networks.

Q7. What is AI in smart manufacturing?

It’s factory-wide automation and intelligence powered by connected systems, real-time insights, and autonomous control.

HIRE A TOP SOFTWARE DEVELOPMENT COMPANY

Verified

Expert in Software & Web App Engineering

Verified

Expert in Software & Web App Engineering

I am Manish Kumawat, co-founder of Fulminous Software, a top leading customized software design and development company with a global presence in the USA, Australia, UK, and Europe. Over the last 10+ years, I am designing and developing web applications, e-commerce online stores, and software solutions custom tailored according to business industries needs. Being an experienced entrepreneur and research professional my main vision is to enlighten business owners, and worldwide audiences to provide in-depth IT sector knowledge with latest IT trends to grow businesses online.

Partner with Top-Notch Web Application Development Company!

Discuss your Custom Application Requirements on info@fulminoussoftware.com or call us on +1-903 488 7170.

15 Days Risk-Free Trial