Predictive Maintenance Best Practices For Manufacturers

Manish kumawat

Last Updated on: 07 October 2025

Let’s begin with a common example into consideration. When you go to the doctor, they don't just wait for you to get sick to treat you. They run tests, check your vitals, and even predict potential health issues before they become serious problems. That's basically what predictive maintenance is for your factory.

Instead of waiting for your machines to break down and cause costly downtime, you're giving them a regular checkup. We're talking about using smart technology to monitor the health of your equipment. It's like having a tiny doctor inside each machine, sending out alerts when something's off.

It is just like your doctor uses your blood pressure, heart rate, and other vital signs to assess your health. We use data from your machines to understand conditions. Just like finding a small mole on your skin before it turns into something bigger predictive maintenance works. By looking at this data, we can notice early signs of problems, like a machine getting too hot or shaking too much.

Are you searching for ways to cut down production costs, maintenance costs, and maintenance time, and increase overall efficiency? Then the following information is for you! Because predictive analytics delivers a tenfold return on investment and reduces costs by 30% to 40% (source).

We'll discuss how to keep your factory running smoothly with predictive maintenance and how to make benefits of it. We'll cover everything from finding the right techs to watch to using fancy data to predict problems.

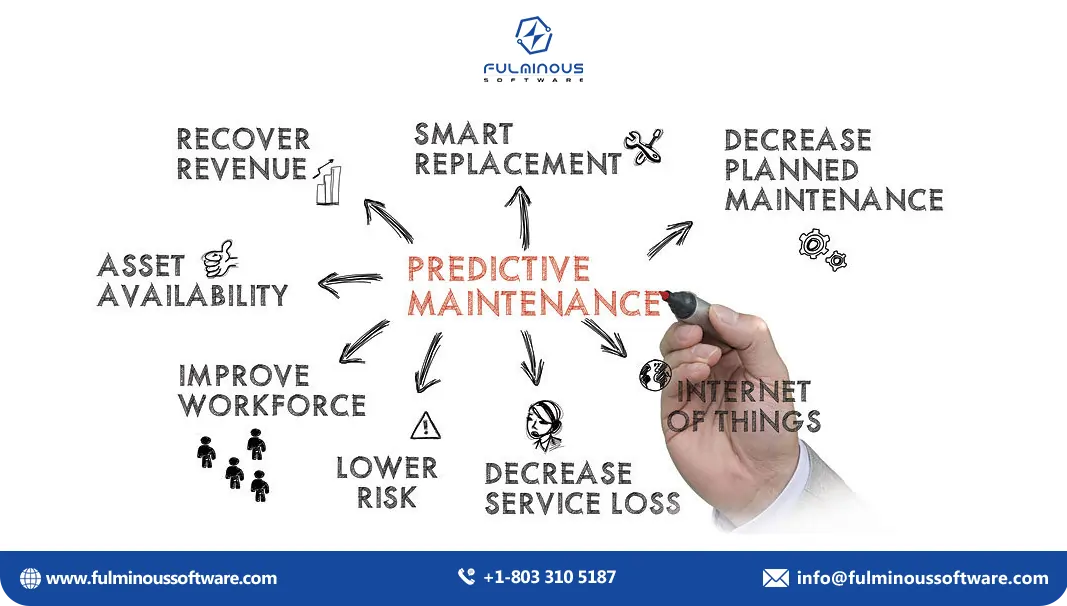

Why Predictive Maintenance?

Manufacturing and other industrial activities can never be the same after using predictive maintenance. It indicates a change in strategy from preventive and reactive maintenance procedures to one that is more proactive. Let's see why it's an essential component of modern manufacturing operations:

1. Minimize Downtime

Unplanned downtime is costly: Every minute of unexpected equipment failure translates into lost production, revenue, and customer satisfaction.

Predictive maintenance helps anticipate failures: By keeping an eye on equipment health in real time, you can plan maintenance ahead of time and stop big breakdowns from happening.

2. Optimize Asset Lifespan

Extend equipment life: By finding and fixing problems early, you can make your machines last longer and avoid replacing them too soon.

Improve asset performance: Continuous monitoring allows for performance optimization, ensuring equipment operates at peak efficiency.

3. Reduce Maintenance Costs

Efficient resource allocation: Predictive maintenance helps prioritize maintenance tasks based on actual equipment conditions, removing unnecessary work.

Optimize spare parts inventory: Accurate predictions of equipment needs help manage inventory levels effectively, reducing costs.

Avoid costly repairs: Early detection of issues prevents major breakdowns, which can be significantly more expensive to repair.

4. Improve Safety

Identify potential hazards: By monitoring equipment health, you can identify conditions that could lead to accidents or injuries.

Proactive safety measures: Address safety concerns before they become critical incidents.

5. Enhance Production Efficiency

Optimized production schedules: Better planning and scheduling of maintenance tasks is made possible by predictive maintenance, which reduces production interruptions.

Increased productivity: Reduced downtime and improved equipment performance contribute to overall operational efficiency.

6. Data-Driven Decision Making

Informed decisions: Predictive maintenance relies on data analysis to make informed decisions about maintenance strategies.

Continuous improvement: By analyzing maintenance data, you can identify areas for improvement and optimize your maintenance processes.

7. Competitive Advantage

Enhanced customer satisfaction: Reduced downtime and higher product quality lead to increased customer satisfaction.

Market leadership: Adopting predictive maintenance demonstrates a commitment to innovation and operational excellence.

Seeing the Above Description, You May Feel Like an Academic Stuff. So Let’s See Some Real Statistics:

PWC report shows, that predictive maintenance in industries has the potential to:

- Cut expenses by 12%

- Increase uptime by nine percent.

- Cut the risks to quality, safety, health, and the environment by 14%.

- Increase an aging asset's lifespan by twenty percent

A report by CXP Group says that 93% of manufacturers using predictive maintenance have seen improvements in their old equipment, and 91% have noticed shorter repair times and less unexpected downtime.

According to the latest survey:

- Preventive maintenance is used in 80% of manufacturing plants, and more than half of them use predictive maintenance.

- 79% of businesses say they mainly use industrial data analytics for predictive maintenance.

- Bad maintenance practices can lower a business's production by 20%, but predictive maintenance helps prevent that.

- Predictive maintenance can cut down the amount of downtime, which usually costs factories between 5% and 20% of their total production.

So, predictive maintenance is essentially a calculated investment that maximizes asset uptime, lowers expenses, and enhances overall operational performance to yield significant returns.

10 Predictive Maintenance Best Practices Every Manufacturer Should Know

In every process, you need to understand the best practices to achieve success. Here are some Predictive Maintenance best practices to guide your implementation:

-

Identify Critical Assets

All equipment isn't created equal. Start by pinpointing the assets that are crucial to your production process. These are the machines that, if they fail, would cause the most significant disruption and financial loss. Prioritize your efforts on these assets to maximize the return on your PdM investment. -

Establish Clear Performance Metrics

Define what success looks like for your PdM program. Key performance indicators (KPIs) could include:- Mean time between failures (MTBF)

- Overall equipment effectiveness (OEE)

- Reduction in unplanned downtime

- Maintenance cost per unit of output

-

Build a Strong Data Foundation

PdM is data-driven. Invest in sensors, data collection systems, and a robust data management infrastructure. Make sure that the data is readily available, regular, and reliable. This foundation will support your predictive models and decision-making. -

Leverage Advanced Analytics

Use cool tools and tricks to dig into your data and find out what’s really going on. Machine learning and artificial intelligence can help identify patterns, predict failures, and optimize maintenance schedules. Consider partnering with data scientists or analytics experts to maximize the value of your data. -

Implement a CMMS

A computerized maintenance management system (CMMS) is essential for managing maintenance operations and storing asset information. It provides a centralized platform for work orders, spare parts inventory, and maintenance history. Look for a CMMS with advanced analytics capabilities to support your PdM efforts. -

Train Your Workforce

PdM requires a skilled workforce. Train maintenance workers, engineers, and others on how to analyze data, use predictive models, and work with PdM tools. Empower employees to become proactive problem-solvers. -

Start Small, Scale Gradually

Don't try to implement PdM across your entire operation at once. Start your journey with a pilot project on a small scale. This helps you improve your methods, gain skills, and show how useful PdM is before using it in other areas. -

Foster a Culture of Continuous Improvement

PdM is an ongoing journey. Promote a habit of experimentation, learning, and adaptation. Regularly review your PdM program, identify opportunities for improvement, and make adjustments as needed. -

Integrate PdM with Other Initiatives

Combine PdM with methods like reliability-centered maintenance (RCM) and total productive maintenance (TPM) to manage your assets more effectively. Using these extra strategies can make your PdM program work even better. -

Partner with Experts

Consider partnering with external experts who specialize in PdM. They can provide valuable guidance, support, and technology solutions. This can accelerate your implementation and help you achieve better results.

By following these best practices, you can set up a successful PdM program that brings great benefits to your manufacturing operation. Remember, PdM is not just about technology; it's about people, processes, and data working together to optimize asset performance.

Cool Technologies That Can Help You In Predictive Maintenance

You need some tech magic to achieve top-class predictive maintenance! Let's talk about the cool gadgets that can help you predict when something's about to go wrong.

Sensors: The Factory's Eyes and Ears

Imagine your machines are superheroes, and sensors are their superpowers. These tiny little devices keep an eye on everything, from temperature to vibration. They're like your factory's eyes and ears, gathering all the data.

The Internet of Things (IoT): The Ideal Tool

IoT is like a superhighway for data. It connects all your machines and sensors, so they can talk to each other. This is how you get a big scenery of what's happening in your factory.

Cloud Computing: The Brain of the Operation

Think of the cloud as your factory's super-smart assistant. It stores all the data collected by your sensors and crunches numbers to find patterns.

Artificial Intelligence (AI): The Future Teller

AI is the magic tool that turns data into predictions. It learns from past patterns and can forecast when a machine might break down.

Augmented Reality (AR): Fixing Things Faster

AR is like having an X-ray report for your machines. It helps technicians look inside the equipment and fix problems faster by mixing digital info with what they see outside.

Digital Twins: A Virtual Factory

A digital twin is a virtual copy of your factory. It lets you test different scenarios and see how changes will affect your operations. It's like having a practice factory before you try something new in the real world.

These tech tools are like the Avengers of the manufacturing world, working together to protect your factory from downtime. But in the next section, we are going to reveal the best tool for manufacturing predictive maintenance.

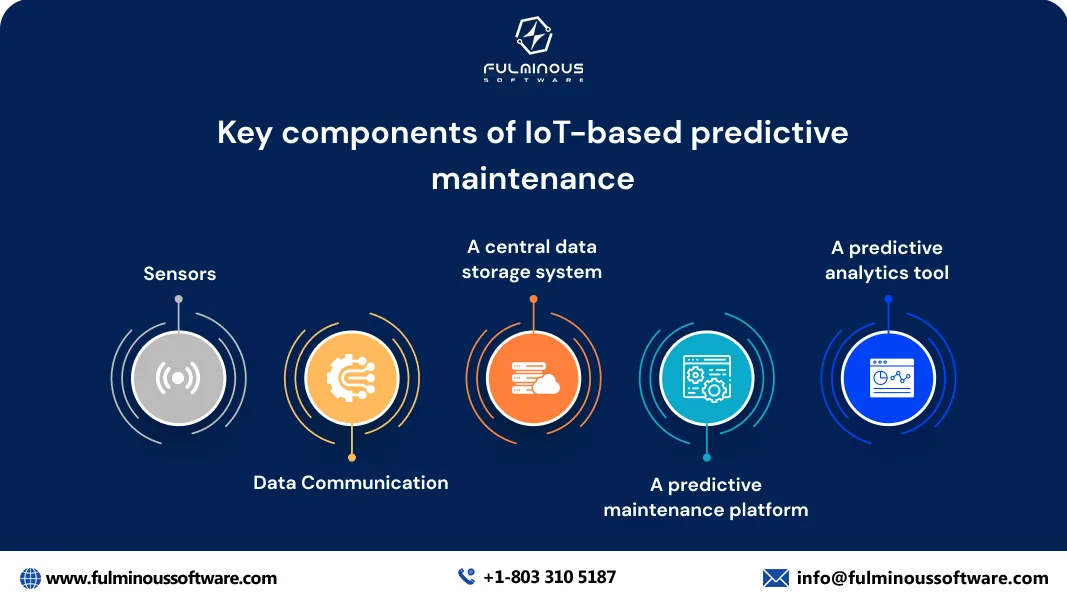

See Why IIoT Is The Ideal Tool for Predictive Maintenance

Even though there are many tools for predictive maintenance in your factory, the Industrial Internet of Things (IIoT) is the best choice. As a trending tool, IIoT also offers plenty of features other than predictive maintenance. Let's see why IIoT is the ideal tool:

How IIoT Powers Predictive Maintenance

The main part of IIoT-enabled predictive maintenance is collecting and analyzing lots of data from connected machines. This data includes:

- Vibration data: Detects imbalances, misalignments, and bearing wear.

- Temperature data: Identifies overheating, lubrication issues, and electrical problems.

- Pressure data: Keeps an eye on the functionality of the equipment and looks for leaks.

- Power consumption data: Reveals energy efficiency and potential equipment failures.

- Operational data: Tracks machine usage, cycles, and load.

These data points, when combined with advanced analytics and machine learning algorithms, allow manufacturers to perform predictive maintenance.

Challenges and Considerations

While IIoT offers immense potential, implementing predictive maintenance is not without challenges.

- Data Quality: Ensuring data accuracy and reliability is crucial for effective predictive modeling.

- Data Security: It's critical to defend sensitive data against online attackers.

- Infrastructure Costs: Investing in sensors, network, and analytics platforms can be costly.

- Skill Gap: Finding personnel with the necessary data science and maintenance expertise can be challenging.

- Change Management: Overcoming resistance to change and building a culture of data-driven decision-making is essential.

Cost of Implementing IIoT For Predictive Maintenance in Manufacturing Business

The cost of implementing IoT for predictive maintenance can vary wildly depending on a few things:

- The size of your factory: A small shop will cost less than a giant factory with hundreds of machines.

- How many sensors do you need: More sensors mean more data, which can get pricey.

- The complexity of your equipment: Some machines need more sensors and advanced analytics than others.

- Software and hardware costs: You'll need to invest in IoT platforms, data analytics tools, and maybe new equipment.

- Installation and setup: Getting everything up and running takes time and money.

- Training your team: Your workers need to learn how to use the new tech.

While the upfront costs might seem steep, think of it as an investment in your factory's future. By preventing costly breakdowns and improving efficiency, IoT can actually save you money in the long run.

Remember, you don't have to do it all at once. You can start small and gradually expand your IoT setup. The key is to find the right balance between cost and benefits.

Case Study: Golden International Plastic Factory's Success with Predictive Maintenance

Golden International Plastic Factory (GIPF), is a leading manufacturer in the plastic industry. Before integrating predictive maintenance with the assistance of IIoT, they were facing significant challenges.

Like many factories, GIPF used reactive maintenance, which often caused surprise machine breakdowns, expensive repairs, and production delays. The GIPF owners wanted to find a good tool to fix these problems. After searching for a tool for one and a half years, they found that nothing can replace IIoT now and it will also be useful in the future.

The Problem: Downtime and Maintenance Costs

GIPF was struggling with frequent unplanned downtime. Every minute a machine was down meant lost production and missed deadlines, leading to decreased customer satisfaction. The factory had high maintenance costs because of emergency repairs and replacement equipment too soon, which could have been saved with quick action.

GIPF's leadership team realized that their traditional maintenance approach was a failure. They needed a more proactive strategy to keep their machines running smoothly, reduce costs, and improve overall efficiency.

The Solution: Implementing Predictive Maintenance

GIPF decided to adopt predictive maintenance with the assistance of IIoT which helps to predict when equipment might fail. By installing sensors on all machinery, GIPF could monitor vital signs like temperature, vibration, and power consumption.

These sensors collected vast amounts of data. We used machine learning to study the data, find patterns, and predict problems before they become serious.

GIPF started small, focusing on its most critical assets. They implemented a pilot project on one production line, which allowed them to refine their processes and demonstrate the value of PdM. With the success of the pilot, GIPF gradually expanded predictive maintenance across the entire factory.

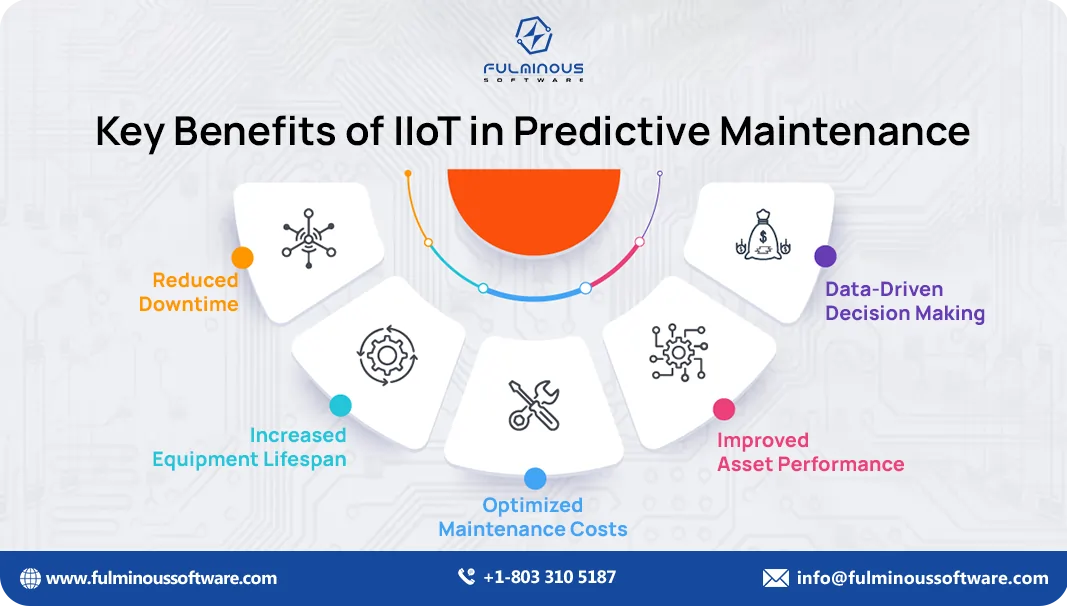

The Results: Impressive Gains Across the Board

- Reduced Downtime: GIPF experienced a 20% reduction in unplanned downtime.

- Lower Maintenance Costs: Predictive maintenance helped GIPF cut maintenance costs by 25%.

- Increased Equipment Lifespan: The factory saw a 15% increase in the lifespan of its machinery.

- Improved Operational Efficiency: With less downtime and optimized equipment performance, GIPF's overall operational efficiency improved by 12%.

- Enhanced Safety: The factory reported a 10% reduction in safety incidents, creating a safer work environment for their employees.

Golden International Plastic Factory's journey with predictive maintenance shows the power of predictive maintenance strategies in the manufacturing process.

Conclusion

So, predictive maintenance isn't just some fancy tech term; it's a growth booster for your manufacturing factories. You can save thousands of dollars, make your customers satisfied, and even get peace of mind always knowing your manufacturing factory is running smoothly.

Remember, IoT development is the best option to activate predictive maintenance in your factory. You need a group of smart people to do this job for you. Start small, focus on what matters most, and don't be afraid to ask for help.

Predictive maintenance helps you see the future, so you can plan ahead and avoid those nasty surprises. It’s an investment that pays great ROI.

So, are you ready to give your factory a health checkup? Let's get started!

FAQs

Q1: What is predictive maintenance?

A: Predictive maintenance uses data to keep an eye on machines, predicting problems before they happen, reducing downtime, and improving performance.

Q2: How does predictive maintenance reduce downtime?

A: It regularly checks how machines are doing, so you can fix things before they break and avoid unexpected stops.

Q3: What are the key benefits of predictive maintenance?

A:

- Reduced maintenance costs

- Extended equipment lifespan

- Increased operational efficiency

Q4: How does IoT enhance predictive maintenance?

A: IoT uses sensors to gather real-time data, helping predict and prevent machine failures before they happen.

Q5: What role does AI play in predictive maintenance?

A: AI studies data to find patterns and predict when machines might fail, helping plan maintenance and reducing unexpected breakdowns.

Q6: Why is data quality important in predictive maintenance?

A: Good data makes predictions more reliable, which is important for planning maintenance and making decisions.

Q7: What challenges are associated with implementing predictive maintenance?

A: Challenges include keeping data safe, paying for new technology, finding skilled workers, and helping people adjust to the changes.

Q8: Can predictive maintenance be implemented gradually?

A: Yes, it's smart to start with important machines, improve the process, and slowly add more as you gain experience and show it works.

Q9: How does predictive maintenance impact safety?

A: By spotting dangers early, predictive maintenance makes the workplace safer and helps prevent accidents.

Q10: Is predictive maintenance cost-effective for all manufacturers?

A: Yes, it can save money by avoiding costly repairs and downtime, though the starting cost depends on the factory's size and needs.

HIRE A TOP SOFTWARE DEVELOPMENT COMPANY

Verified

Expert in Software & Web App Engineering

Verified

Expert in Software & Web App Engineering

I am Manish Kumawat, co-founder of Fulminous Software, a top leading customized software design and development company with a global presence in the USA, Australia, UK, and Europe. Over the last 10+ years, I am designing and developing web applications, e-commerce online stores, and software solutions custom tailored according to business industries needs. Being an experienced entrepreneur and research professional my main vision is to enlighten business owners, and worldwide audiences to provide in-depth IT sector knowledge with latest IT trends to grow businesses online.

Partner with Top-Notch Web Application Development Company!

Discuss your Custom Application Requirements on info@fulminoussoftware.com or call us on +1-903 488 7170.

15 Days Risk-Free TrialRecommended Articles