10 Proven Strategies to Improve Operational Efficiency in Manufacturing

Manish Kumawat

Last Updated on: 07 October 2025

In a manufacturing business, every second, every movement on the production floor values thousands of dollars and manufacturers face huge pressure to produce high-quality goods, faster and at lower costs. That is why operational efficiency is to be enhanced day by day in the manufacturing business. Each and every manufacturer is in search of ways to improve their operational efficiency and go ahead of competitors.

It is a fact that the challenges are many to maintain or improve operational efficiencies of the manufacturing process. But how do you identify and eliminate inefficiencies that are silently draining your profits?

There comes the role of the latest technologies that can make these heavy tasks simpler. Here we'll reveal a trending technology that offers you 10 proven strategies to improve your operational efficiency.

Get ready to:

- Maximize operational efficiencies.

- Reduce waste and enhance production flows.

- Get the benefit of trending technologies.

- Boost your employees to achieve their maximum potential.

- Utilize the power of data-driven decision-making

- Consistently monitor and enhance your manufacturing processes.

Whether you're a well-established manufacturer or just a manufacturing startup, these strategies can be implemented at any scale. So, get ready to unlock the full potential of your manufacturing operation!

What is Actually Operational Efficiency in Manufacturing?

In manufacturing, operational efficiency denotes an organization's ability to produce things at maximum output while using the least amount of resources. Manufacturers must minimize costs by streamlining operations, increasing efficiency, and so on.

Operational efficiency plays an important role in almost all sectors, it is especially crucial in manufacturing. That is because, in manufacturing, each step of the process contributes not only to the number of things produced and their quality but also to how long it takes to produce an item and how much that item must be sold for a profit. Manufacturers can enjoy immediate benefits by just organizing a few stages.

Why Manufacturing Businesses Need Improvement in Operational Efficiency

Improving operational efficiency offers a multitude of benefits for manufacturing businesses. Here’s why manufacturing businesses need to focus on enhancing their operational efficiency:

- Cut Costs: Less waste, lower energy use, and fewer workers needed = major savings!

- Beat Competitors: Offer high-quality products at lower prices, leaving them behind.

- Top-Notch Products: Catch errors early, and produce perfect products every single time.

- Fast Production: Make more products faster, meet sky-high demands, and become a manufacturing industry hero.

- Smart Resource Use: No more disappearing materials or energy-wasting machines. Get the most out of everything.

- Safety First: Efficient workplaces are safer workplaces, fewer accidents, and happy employees.

- Adapting to Change: The world changes fast, but efficient factories can keep up with ease.

- Happy Customers: Deliver on time, every time, with perfect quality. That's a recipe for customer satisfaction!

- Future-Proof Factory: Sustainable practices save money and help the environment, keeping your factory strong.

IoT: The Trending Tool for Improving Operational Efficiency of Manufacturing

Do you know? The best choice for manufacturing businesses to improve operational efficiency is the Internet of Things (IoT). When you get into the amazing world of IoT, you will know why we admire IoT. Manufacturers collect and analyze data in real-time with IoT and it leads to maximum productivity, cost savings, and overall operational effectiveness.

IoT refers to the network of interconnected devices and systems that communicate with each other and exchange data. In the current scenario, It is not an exaggeration we say there is no replacement for IoT.

The Industrial IoT market is rapidly adopting smart manufacturing technologies, transforming industry operations and increasing productivity. The global Industrial IoT market is expected to expand significantly in revenue and is predicted to have a high annual growth rate (CAGR 2024-2029) of 13.79%, resulting in a market volume of US$454.90 billion by 2029. (source)

According to the Ubisense Survey, 62% of manufacturers use IoT technologies in their production or assembly operations. (source)

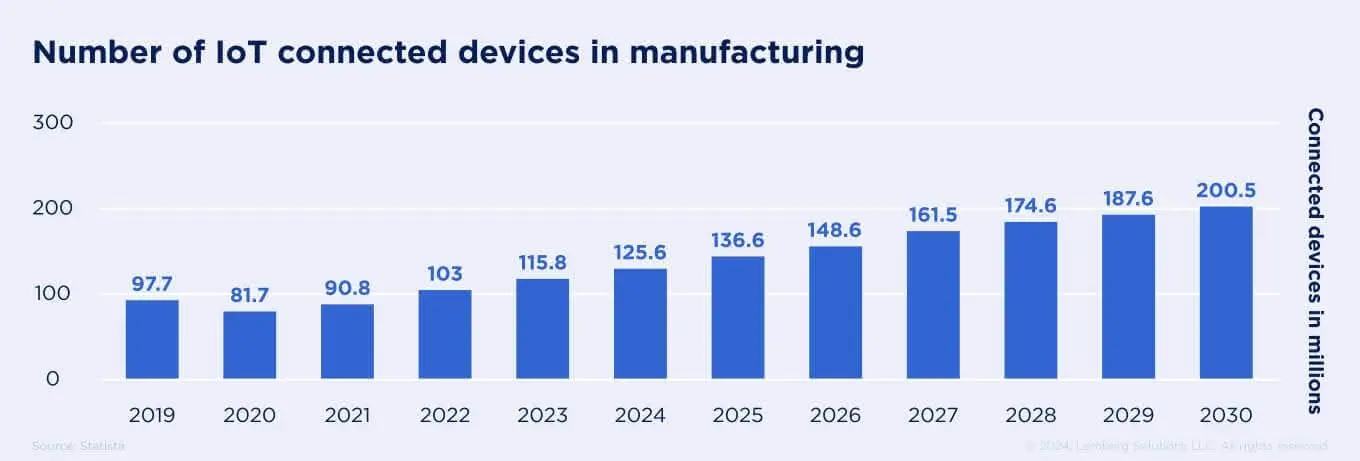

Manufacturing is one of the world's fastest-growing industries, with over 125.6 million items connected via IoT by 2024. (source)

Are you excited to know how IoT improves the operational efficiencies of manufacturing businesses? See the next section.

Improve Operational Efficiency in Manufacturing with IoT: 10 Proven Strategies

1. Predictive Maintenance

One of the best approaches to achieving this operational efficiency is through predictive maintenance with the Internet of Things (IoT). The word Predictive maintenance itself proves that it uses IoT technology to monitor equipment in real-time, predicting possible failures before they occur. The use of predictive maintenance decreases downtime, manages maintenance schedules, and improves overall operational efficiency.

The Role of IoT in Predictive Maintenance

- IoT sensors continuously monitor parameters such as temperature, vibration, and pressure. This informs the operational status of equipment.

- IoT devices collect information from various sources and detect issues.

- IoT systems evaluate the collected data to detect patterns, trends, and deviations that may indicate potential failures.

- IoT systems predict when and where equipment failures might occur and enable proactive maintenance actions.

- Based on predictive insights, maintenance can be scheduled during planned downtimes rather than waiting for unexpected failures

- IoT technology helps to find issues before they turn into serious failures.

- Continuous monitoring of machine conditions allows for accurate assessment of its health.

Real-Life Case Study: General Motors

General Motors (GM), one of the largest automobile manufacturers in the world, implemented predictive maintenance across its production lines using IoT technology. GM faced significant challenges with unplanned downtime, which was impacting its production schedule and increasing costs. GM equipped its machinery with IoT sensors to monitor various operational parameters in real time.

Results:

- Reduced Downtime: GM experienced a 30% reduction in unplanned downtime. The ability to predict and address issues before they cause a failure allowed for maintenance to be scheduled during planned downtimes.

- Cost Savings: The company saw a 20% decrease in costs of maintenance.

- Improved Operational Efficiency: With machinery running more reliably, GM increased its overall production efficiency.

2. Real-Time Monitoring and Control

Real-time monitoring and control are crucial for maintaining operational efficiency. Manufacturers are getting unmatched visibility into their operations through the integration of the Internet of Things (IoT) with this. Efficiency, productivity, and general competitiveness all significantly increase with this strategy.

The Role of IoT in Real-Time Monitoring and Control

- IoT devices detect data continuously on various parameters, such as machine performance, production rates, and environmental conditions.

- IoT systems aggregate data from multiple sources and give a complete overview of the manufacturing process.

- IoT systems generate real-time alerts and notifications based on predefined thresholds or detected anomalies.

- IoT technology enables automated control of manufacturing processes.

- IoT provides enhanced visibility that allows operators and managers to monitor and control production lines, machinery, and other critical components more effectively.

- IoT systems enable remote monitoring and control of manufacturing operations that allow operators to oversee and manage processes from off-site locations, improving flexibility and responsiveness.

Real-Life Case Study: Siemens

Siemens, a global powerhouse in industrial automation, implemented IoT-driven real-time monitoring and control in its manufacturing plants to enhance operational efficiency.

Results:

- Increased Efficiency: Siemens achieved a 20% increase in production efficiency.

- Reduced Downtime: The system's ability to provide instant alerts and automated responses reduced unplanned downtime by 25%.

- Improved Product Quality: Consistent monitoring of critical parameters ensured that products met stringent quality standards. Siemens reported a 15% reduction in product defects.

- Energy Savings: Real-time control of energy-consuming equipment led to a 10% reduction in energy costs.

3. Asset Tracking and Management

Traditional methods of tracking and managing assets can be inefficient. The Internet of Things (IoT) changes the scenario by providing real-time visibility and control over assets. Operational efficiency can be increased several times by this.

The Role of IoT in Asset Tracking and Management

- IoT devices like GPS trackers and RFID tags continuously monitor and report the location of assets.

- IoT sensors assess the health of assets and identify maintenance needs.

- IoT systems automate inventory tracking and management which also minimizes errors in inventory records.

- IoT technology helps manage the entire lifecycle of assets from acquisition to disposal.

- IoT provides information about asset utilization patterns that can lead to increased productivity and efficiency.

- IoT-enabled security features such as geofencing and tamper detection enhance asset security.

- IoT platforms generate comprehensive data reports on asset performance, usage, and condition.

Real-Life Case Study: Harley-Davidson

Harley-Davidson, a renowned motorcycle manufacturer, faced challenges in managing its vast inventory of manufacturing assets spread across multiple locations.

Results:

- Increased Asset Utilization: Harley-Davidson experienced a 15% increase in asset utilization.

- Reduced Inventory Costs: With improved visibility into asset locations and conditions, the company reduced its need for excess inventory by 20%.

- Enhanced Maintenance Efficiency: Condition monitoring enabled preventive maintenance, reducing unexpected breakdowns by 30%.

- Operational Efficiency: Automated tracking and management streamlined operations, reducing the time spent on manual asset tracking and administrative tasks.

4. Supply Chain Optimization

The Internet of Things (IoT) offers real-time visibility, better collaboration, and data-driven decision-making for supply chain optimization. IoT technology can improve the operational efficiency of manufacturers in various stages of supply.

The Role of IoT in Supply Chain Optimization

- IoT technology provides live status and location of goods throughout the supply chain.

- IoT technology facilitates detailed tracking of products from suppliers to end consumers.

- IoT data provides information about consumption patterns and market trends.

- IoT systems automate inventory tracking by updating stock levels live.

- IoT technology monitors transportation conditions, vehicle performance, and route efficiency.

- IoT-enabled platforms facilitate real-time data sharing and collaboration among supply chain partners.

- IoT sensors can detect and alert responsible persons to potential disruptions or risks.

- IoT technology helps in reducing operational costs. Improved inventory management, efficient logistics, and better demand forecasting.

Real-Life Case Study: Coca-Cola

Coca-Cola, one of the world's largest beverage manufacturers, implemented IoT technology to optimize its supply chain and improve operational efficiency. The Extensive network of suppliers, production facilities, and distribution channels were the major reasons for the challenges.

Results:

- Enhanced Visibility: Coca-Cola achieved complete end-to-end visibility of its supply chain, allowing for real-time tracking of products and more accurate delivery estimates.

- Inventory Optimization: The company reduced excess inventory by 15%, leading to significant cost savings in storage and logistics.

- Improved Collaboration: Real-time data sharing improved collaboration with suppliers and distributors, resulting in more synchronized operations and better demand forecasting.

- Reduced Lead Times: By optimizing the supply chain, Coca-Cola reduced lead times by 20%, ensuring faster delivery of products to retailers and customers.

- Increased Responsiveness: The IoT-enabled supply chain allowed Coca-Cola to quickly adapt to changes in demand and supply conditions, enhancing its ability to meet customer needs.

5. Quality Control and Assurance

Quality control and assurance (QC/QA) processes are important to check that products meet specified standards and customer expectations. The integration of the Internet of Things (IoT) into QC/QA offers real-time monitoring, data analytics, and automated reporting. Manufacturers can increase operational efficiency with this.

The Role of IoT in Quality Control and Assurance

- IoT sensors continuously monitor parameters to ensure that production conditions remain within specified tolerances and standards.

- IoT systems automate the collection of quality-related data from various stages of production.

- IoT analysis identifies patterns, detects anomalies, and predicts potential quality issues before they impact the final product.

- IoT technology enables immediate feedback on production quality.

- IoT facilitates detailed traceability of products to quickly pinpoint the source of quality issues.

- IoT systems can predict potential quality issues and suggest preventive measures.

- IoT solutions integrate with other manufacturing systems, such as Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES).

- IoT-driven quality control ensures that production processes are consistently monitored and controlled.

Real-Life Case Study: Siemens

Siemens, a global leader in industrial automation and manufacturing, implemented IoT-enabled QC/QA processes to enhance product quality and operational efficiency in its manufacturing plants.

Results:

- Improved Product Quality: Siemens achieved a 20% reduction in product defects. Real-time monitoring and early defect detection ensured that quality issues were addressed promptly.

- Increased Efficiency: The company got a 15% increase in operational efficiency.

- Cost Savings: The company reported a 10% reduction in manufacturing costs.

- Enhanced Compliance: Automated monitoring and reporting ensured compliance with industry standards and regulations, reducing the risk of non-compliance penalties.

- Customer Satisfaction: Improved product quality and consistency enhanced customer satisfaction and strengthened Siemens' market position.

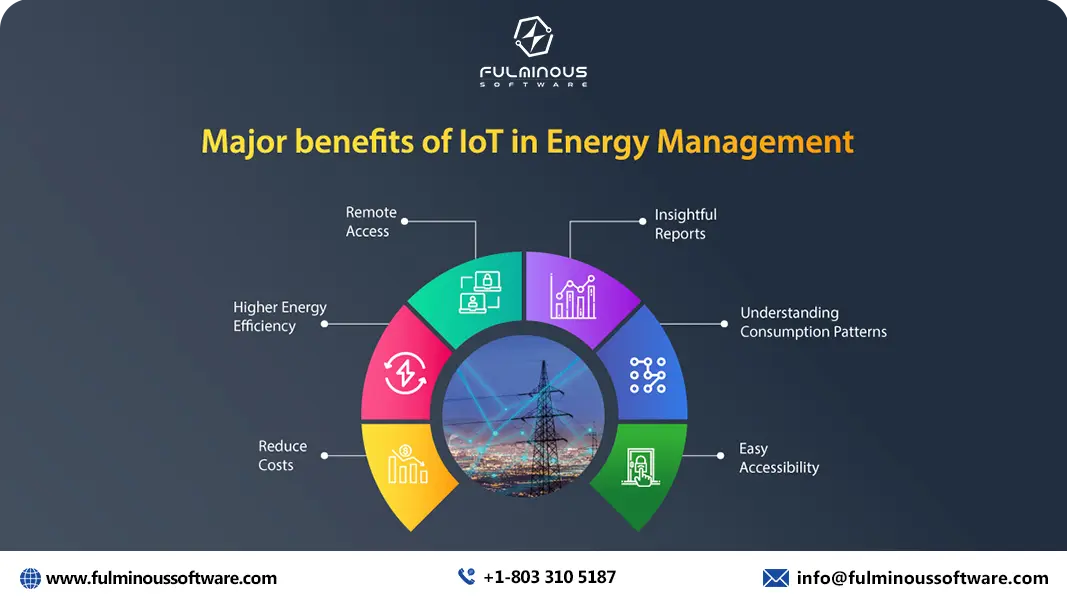

6. Energy Management

Manufacturers are under pressure to optimize their energy consumption with rising energy costs and increasing environmental regulations. The Internet of Things (IoT) integration into energy management offers the best approach to monitoring, controlling, and reducing energy usage.

The Role of IoT in Energy Management

- IoT sensors and devices continuously monitor energy consumption in real-time across various systems and equipment.

- IoT technology facilitates the integration of smart grids, enabling dynamic management of energy supply and demand.

- IoT-enabled automation systems can control lighting, heating, cooling, and other energy-consuming devices based on real-time data and predefined parameters.

- IoT sensors monitor the performance and condition of energy systems, predicting potential failures and maintenance needs before they occur.

- IoT devices collect and analyze data on energy consumption, identifying areas where energy use can be reduced without compromising operational efficiency.

- IoT technology aids in the management and optimization of renewable energy sources such as solar panels and wind turbines.

Real-Life Case Study: General Electric (GE)

General Electric (GE), a global leader in industrial manufacturing, implemented IoT technology to enhance its energy management practices across its manufacturing facilities.

Results:

- Energy Savings: GE achieved a 15% reduction in energy consumption across its manufacturing facilities.

- Improved Efficiency: The company reported a 10% increase in operational efficiency.

- Cost Reduction: GE realized substantial cost savings, with energy expenses decreasing by 12%.

- Sustainability Goals: The reduction in energy consumption contributed to GE’s sustainability goals.

- Predictive Maintenance: IoT-enabled monitoring helped predict and address equipment issues before they led to energy inefficiencies, further enhancing operational efficiency.

7. Enhanced Workforce Productivity

Innovative solutions of IoT improve the workforce productivity of manufacturers by integrating smart technologies. It streamlines operations, improves communication, and provides valuable insights into worker performance.

The Role of IoT in Enhancing Workforce Productivity

- IoT devices, such as wearable sensors and smart tools, provide real-time feedback on worker performance and health.

- IoT-enabled communication tools facilitate better coordination and information sharing among team members.

- IoT technology can automate daily tasks and manage operations.

- IoT sensors monitor equipment conditions and predict potential failures.

- Wearable IoT devices can monitor workers' physical conditions and provide alerts for unsafe practices or ergonomic issues.

Real-Life Case Study: Bosch

Bosch, a global leader in technology and manufacturing, implemented IoT technology to enhance workforce productivity in its manufacturing facilities.

Results:

- Increased Efficiency: Bosch achieved a 20% increase in workforce productivity.

- Improved Communication: Enhanced communication tools improved team coordination and information sharing, leading to more effective collaboration and fewer delays.

- Reduced Downtime: Predictive maintenance reduced equipment downtime by 25%.

- Enhanced Safety: Wearable devices improved workplace safety, reducing incidents of injuries by 15%.

- Better Resource Allocation: Data-driven insights allowed Bosch to allocate resources more effectively, optimizing worker assignments and improving overall productivity.

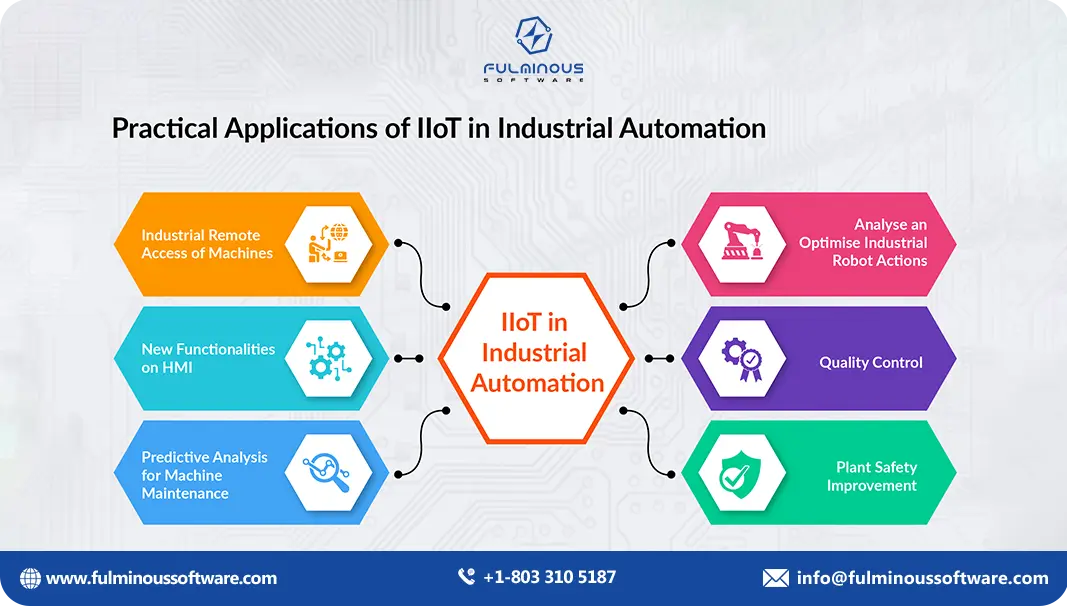

8. Automated and Autonomous Operations

The shift towards automated and autonomous operations represents an important step in achieving high operational efficiency in the manufacturing process. The Internet of Things (IoT) enables smart, interconnected systems that streamline processes, reduce human intervention, and optimize production.

The Role of IoT in Automated and Autonomous Operation

- IoT sensors and devices collect real-time data on various parameters, such as temperature, pressure, and machine status.

- IoT systems provide continuous monitoring of production processes, allowing for real-time control and adjustments.

- IoT data is analyzed using machine learning algorithms to predict trends, detect anomalies, and optimize operations.

- IoT technology integrates with robotic systems to automate repetitive tasks and complex operations.

- IoT-enabled systems allow for remote monitoring and control of manufacturing operations.

Real-Life Case Study: Tesla

Tesla, a leading electric vehicle manufacturer, has leveraged IoT technology to revolutionize its manufacturing operations.

Results:

- Increased Efficiency: Tesla achieved a 30% increase in production efficiency.

- Improved Consistency: Autonomous systems maintained high-quality standards across production lines, resulting in fewer defects and greater product consistency.

- Enhanced Flexibility: The ability to quickly adjust production schedules and processes allowed Tesla to respond rapidly to changes in market demand and optimize production.

- Reduced Downtime: Predictive maintenance and automated controls reduced equipment downtime by 20%, ensuring continuous and uninterrupted production.

- Cost Savings: The implementation of IoT-driven automation led to significant cost savings. Labor costs decreased by 15%.

9. Enhanced Safety and Compliance

The Internet of Things (IoT) offers the best solutions for improving safety and ensuring compliance, while also improving overall operational efficiency. Manufacturers can create safer work environments, adhere to regulatory requirements, and streamline safety management processes by this.

The Role of IoT in Enhancing Safety and Compliance

- IoT sensors continuously monitor environmental conditions and equipment performance, providing real-time data on factors such as temperature, gas levels, and machinery status.

- IoT systems can generate automated alerts and notifications for unsafe conditions or compliance breaches.

- IoT data analytics provide insights into safety trends, incident patterns, and compliance performance.

- IoT technology allows for remote monitoring and control of safety systems.

- IoT systems automate the collection and documentation of safety data, ensuring accurate and comprehensive records for compliance audits and regulatory reporting.

Real-Life Case Study: BASF

BASF, a global chemical manufacturing company, implemented IoT technology to enhance safety and compliance across its production facilities.

Results:

- Response Time: The average response time to safety alerts decreased by 40%, allowing for quicker interventions and mitigating risks more effectively.

- Remote Monitoring Capabilities: Remote monitoring resulted in a 30% improvement in the efficiency of safety operations and allowed for better resource allocation.

- Cost Savings: The company estimated a reduction in safety-related operational costs by 25%.

- Employee Safety and Morale: There was a reported 15% increase in employee satisfaction related to workplace safety.

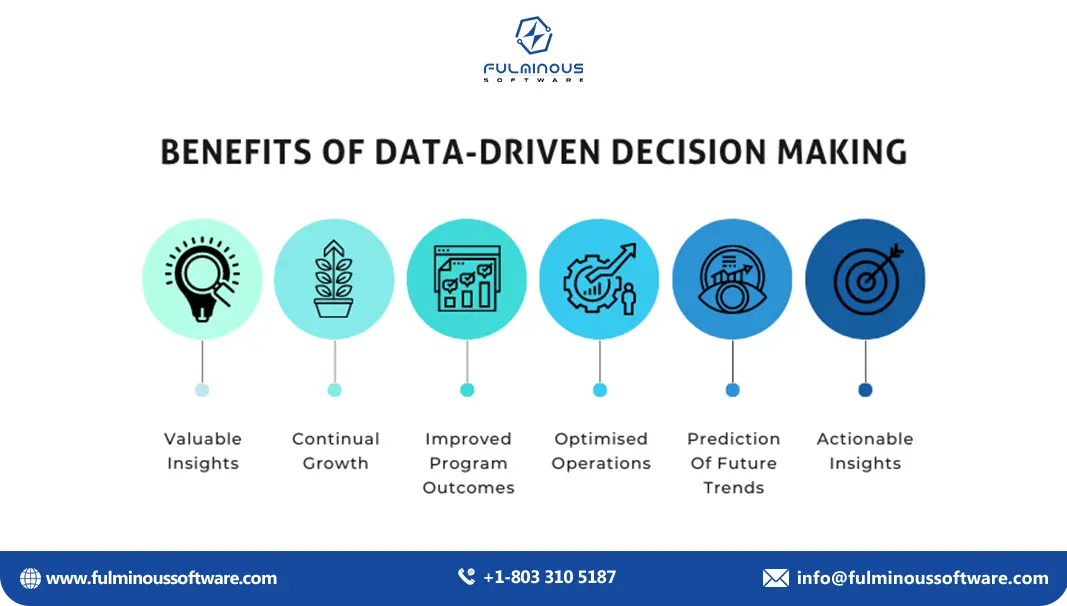

10. Data-Driven Decision Making

The Internet of Things (IoT) provides the necessary infrastructure to collect, analyze, and act upon vast amounts of data generated by manufacturing processes. Manufacturers can make informed decisions, optimize operations, and enhance overall efficiency by leveraging IoT technology.

The Role of IoT in Data-Driven Decision Making

- IoT sensors and devices gather real-time data on various aspects of manufacturing operations, including machine performance, production rates, and environmental conditions.

- IoT systems use advanced analytics and machine learning algorithms to analyze data, identify trends, and detect anomalies.

- IoT technology can predict future outcomes and potential issues by analyzing historical data and identifying patterns.

- IoT provides visibility into all aspects of the manufacturing process, from supply chain management to production line performance.

- IoT systems can automate decision-making processes based on predefined criteria and real-time data.

Real-Life Case Study: Procter & Gamble (P&G)

Procter & Gamble (P&G), a leading consumer goods company, utilized IoT technology to enhance its data-driven decision-making capabilities in its manufacturing operations.

Results:

- Improved Efficiency: P&G achieved a 20% increase in operational efficiency.

- Proactive Maintenance: Predictive maintenance reduced equipment downtime by 25%.

- Enhanced Quality Control: The company reported a 15% reduction in product defects.

- Optimized Resource Allocation: Data-driven decision-making led to more effective allocation of resources, including labor and materials. P&G reduced inventory costs by 10% and improved resource utilization.

- Informed Strategic Planning: Comprehensive data analysis supported strategic planning and alignment with market demands, enhancing overall business performance.

Challenges and Solutions: Overcoming Barriers to IoT Implementation

The Internet of Things (IoT) is supposed to make everything in manufacturing run like clockwork, but sometimes getting it set up can be a challenge. Let's look at some of the roadblocks you might hit and how to get past them:

1. Not Sure Why You Need It:

Sometimes the biggest hurdle is figuring out what problem you're trying to solve with IoT. Just because it's the latest tech doesn't mean it's the right fit for everything.

Solution: Start by identifying areas in your manufacturing process that could be more efficient. Maybe it's preventive maintenance, resource usage, or quality control.

2. Tech Team Needed?

IoT systems can involve a bunch of different skills, from data analysis to IT know-how. If your team is on the lean side, you might worry you can't handle it.

Solution: You don't have to be an expert on everything. Plenty of tech companies like Fulminous Software specialize in setting up and managing IoT systems. Partnering with one can give you the expertise you need without a huge hiring spree.

3. Keeping Things Secure:

Security is a big concern with any internet-connected device. Imagine a hacker messing with your factory robots!

Solution: Make sure any IoT systems you implement have strong security features like encryption and access controls. Keep your software up to date to patch any security holes.

4. Data Overload!

IoT devices collect a lot of data, and figuring out what to do with it all can be overwhelming.

Solution: Invest in data analytics tools that can help you make sense of all the information coming in. You can focus on the insights that matter most for improving your operations.

5. Future-Proofing for Tomorrow:

Technology is constantly changing, so you don't want to get stuck with an outdated system.

Solution: Choose an IoT platform that is flexible and scalable. You can easily add new devices and features as your needs evolve.

The Future of IoT in Improving Operational Efficiency Manufacturing: Trends and Innovations

When you see the upcoming impact of IoT in improving the operational efficiency of manufacturing businesses, you will be amazed!

Artificial Intelligence: Spotting Trouble Before it Starts:

Say goodbye to surprise breakdowns! With IoT sensors and artificial intelligence (AI) working together, factories can now predict when a machine is about to act up.

Virtual Twins: Like a Factory in a Video Game:

Imagine a perfect copy of your factory but in the digital world. Manufacturers test new ideas and spot problems without messing with the real production line. Pretty cool, right?

Edge Computing: Bringing the Cloud Closer:

Imagine processing data without waiting forever. Edge computing crunching numbers closer to where they're collected, factories can make decisions faster and rely less on big computer servers in the cloud. Think of it like having a super-powered mini-computer right on the factory floor.

5G Connectivity: Super-Fast Internet for Super Factories:

The next generation of internet, 5G, is here, and it's super-fast! Factories can connect tons of devices without any lag, making things like remote monitoring and robots that move on their own reality. Faster internet, smoother operations!

Smart Factories: Happy Factories:

Imagine a factory that pretty much runs itself! With a mix of IoT, AI, and other tech, smart factories are becoming a thing. Companies like Bosch and Hitachi are at the forefront of smart factory development.

Sustainable Manufacturing: Going Green with Tech:

Being eco-friendly is a must these days, and IoT is helping factories be more sustainable. Imagine systems that track energy use and help factories cut back on waste.

Invest in IIOT: Maximize ROI by Maximizing Operational Efficiency

If you want to turn your factory into a profit machine, look no further than the Industrial Internet of Things (IIoT)! It's like giving your production line a high-tech upgrade, letting you see and control everything in real time.

Just like Siemens' Amberg Electronics Plant. They're practically printing perfect products and using way less energy, all thanks to IIoT. It's like having a super-powered supervisor constantly monitoring and optimizing everything for peak efficiency.

Investing in IIoT might seem like a big step at first, but it's a future-proof move. You're not just buying gadgets, you're revamping your entire operation for long-term success. So, ditch the guesswork and embrace the IIoT revolution. Watch your ROI grow as your factory transforms into a lean, mean, money-making machine!

Conclusion

Today, in this crazy competitive world of manufacturing, running things efficiently isn't optional - it's essential. Manufacturers gotta use new tech like the Internet of Things (IoT) to maximize operational efficiency.

IoT technology can seriously change the game for manufacturers. By using IoT, factories can make more money, build better things, run smoother, and keep their workers happy. All these will lead to maximum efficiency. Big companies like Tesla, General Motors, and Coca-Cola are already doing this and seeing amazing results.

Getting started with IoT can be tricky. You gotta figure out what you really want to achieve, keep your data safe, not get overwhelmed by all the information, and be ready for even cooler tech in the future. To overcome these hurdles, you gotta plan well, work with a tech expert team like Fulminous Software, and always strive to be better.

The future of manufacturing with IoT is mind-blowing! This will lead to "smart factories" that are super efficient. Investing in Industrial IoT (IIoT) is a smart move for any manufacturer. It'll make your factory run like a cheetah, save you money in the long run, and help you grow your manufacturing business in a sustainable way.

Want to maximize the operational efficiency of your manufacturing business with the latest tech? We can hook you up with super cool Internet of Things (IoT) to make things run smoother. Fulminous is your one-stop solution provider for all things IoT. We can help you set it all up and get the benefits out of it. Don't wait, contact us now, call us at +1 903 488 7170, or shoot us an email at info@fulminoussoftware.com.

FAQs

- Q1: What is operational efficiency in manufacturing?

- A: Operational efficiency in manufacturing refers to producing maximum output with minimal resources, reducing waste, costs, and time while maintaining high product quality.

- Q2: How does IoT improve predictive maintenance?

- A: IoT improves predictive maintenance by using sensors to monitor machines in real-time, predicting failures before they occur, and optimizing maintenance schedules.

- Q3: How does IoT facilitate supply chain optimization?

- A: IoT connects various supply chain elements, allowing for real-time tracking, improved collaboration, data-driven decisions, and more efficient, responsive operations.

- Q4: Why is quality control important in manufacturing?

- A: Quality control ensures products meet specified standards, reducing defects and waste, enhancing customer satisfaction, and maintaining competitive advantage.

- Q5: What role does IoT play in energy management?

- A: IoT supports energy management by giving real-time consumption data, improving usage, integrating smart grids, and allowing predictive maintenance for energy systems.

- Q6: How does IoT enhance workforce productivity?

- A: IoT improves workforce productivity by providing real-time feedback, enhancing communication, automating tasks, and ensuring worker safety through wearable sensors.

- Q7: What are the upcoming changes in IoT?

- A: They are:

- Artificial Intelligence

- Virtual Twins

- Edge Computing

- 5G Connectivity

- Smart Factories

HIRE A TOP SOFTWARE DEVELOPMENT COMPANY

Verified

Expert in Software & Web App Engineering

Verified

Expert in Software & Web App Engineering

I am Manish Kumawat, co-founder of Fulminous Software, a top leading customized software design and development company with a global presence in the USA, Australia, UK, and Europe. Over the last 10+ years, I am designing and developing web applications, e-commerce online stores, and software solutions custom tailored according to business industries needs. Being an experienced entrepreneur and research professional my main vision is to enlighten business owners, and worldwide audiences to provide in-depth IT sector knowledge with latest IT trends to grow businesses online.

Partner with Top-Notch Web Application Development Company!

Discuss your Custom Application Requirements on info@fulminoussoftware.com or call us on +1-903 488 7170.

15 Days Risk-Free TrialRecommended Articles