Digital Transformation Guide for Manufacturing

Manish Kumawat

Last Updated on: 07 October 2025

It would not be an exaggeration if we say most manufacturing business owners feel like their business is stuck in a time warp while the world around is speeding ahead. If you feel the same, it's time to hit the change button — and our Digital Transformation Guide is the perfect place to start!

This overall change includes Digital Transformation, Process Transformation, Organizational Transformation, Strategic Transformation, Cultural Transformation, and Operational Transformation.

Digital transformation is the most important on this list. Our Digital Transformation Guide shows that it's not just a fancy word; it's a lifeline for manufacturing businesses looking to stay relevant, efficient, and profitable.

If a car eventually finds itself stranded on the side of the road and sees others going fast without regular tune-ups and upgrades, the same way, if your manufacturing business is not undergoing transformation according to the needs of the time, you may find it difficult to reach success.

Digital transformation is like giving your business a full-house renovation. It all comes down to replacing outdated, ineffective procedures with advanced, technology-powered alternatives.

When You Go for a New Change in Manufacturing Business, You Must Think About the Following 8 Things:

- What does it mean?

- Why should I go for it?

- What will I get if I go for it?

- What if I don’t go for it?

- What are the steps for it?

- How much do I have to spend on it?

- How much I will get back from it?

- Who will assist me with it?

1. A Digital Transformation Guide to Help You Understand the Basics

Think of digital transformation as giving your business a futuristic makeover. It's like an overall change. Instead of relying on traditional, paper-based methods, you're adopting the latest tech to streamline everything from operations to customer interactions.

In simpler terms, it means using digital tools and technologies to improve how your business works. It's about embracing the digital age and making sure your business isn't left behind.

See some examples that give you a clear idea:

- Online shopping: Instead of having customers visit physical stores, you sell your products directly through your manufacturing website or app.

- Cloud computing: Storing your business data on remote servers instead of local computers, making it accessible from anywhere.

- Automation: Using software to automate repetitive tasks, freeing up your employees to focus on more important work.

- Artificial intelligence (AI): Employing AI-powered tools to analyze data, make predictions, and provide personalized customer service.

Digital transformation isn't just about adopting new tech; it's about changing the way you think about your business. It's about being flexible, innovative, and customer-centric.

Digital transformation is not just about technology; it’s about rethinking how you do business in the digital age. It’s about finding new ways to solve old problems and creating more value for your customers.

2. Why Should I Go for Digital Transformation?

You may think, "What is the need for a transformation if things are working?" The world is changing quickly, and consumers demand more and more. They want stuff faster, they want it to be just right, and they want it to feel like it was made just for them. That's where digital transformation comes in. It's like giving your business an amazing makeover.

Think about it: all the big companies are doing it. They're using new tech to make things faster, cheaper, and way better.

Plus, customers today are picky. They want quick service, personalized stuff, and cool new products. Digital transformation helps you do all that. It's like having a magic wand that makes everything faster and more personalized.

And you know what else? It helps you reach people all over the world. In this connected age, being global is huge. Digital tools make it easy to find and serve customers from anywhere.

And let's not forget about those manual errors and staffing shortages. Digital tools can automate a lot of stuff, so you make fewer mistakes and your team can focus on the important stuff.

Bottom line: Digital transformation is like wearing a superhero cape. It helps you stay ahead of the game, keep your customers happy, and make your business a winner in this fast-paced world.

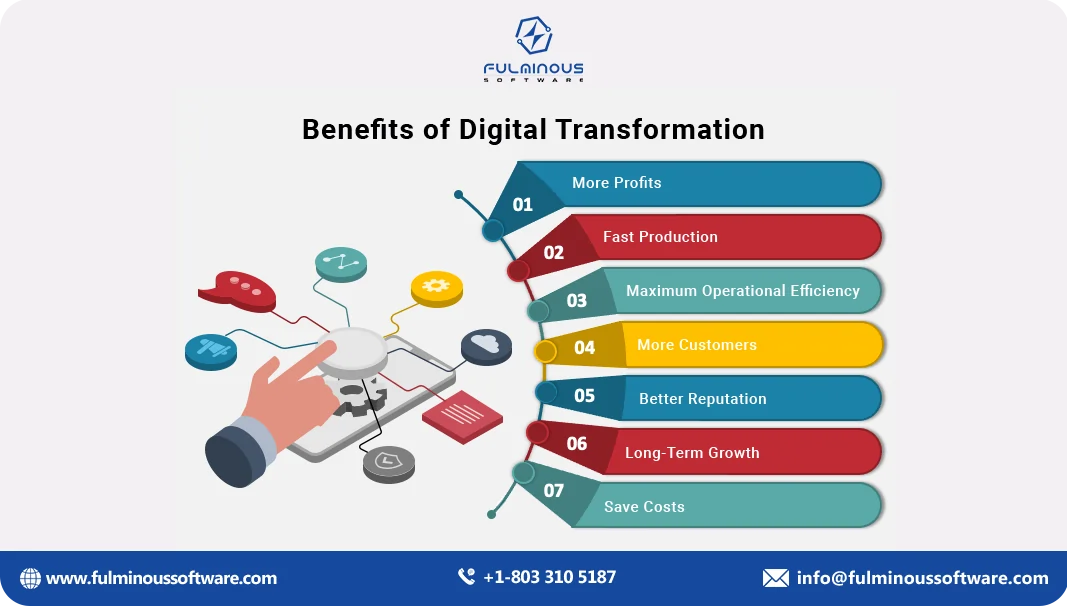

3. What Will I Get If I Go for Digital Transformation?

Digital transformation offers a range of benefits that can significantly improve your business:

- Efficiency Gains: By automating processes and using smart systems, you can produce more products in less time with fewer errors.

- Cost Reduction: Digital tools can help you reduce waste, optimize resource use, and prevent costly errors.

- Better Decision-Making: With access to real-time data, you can make informed decisions that improve production, reduce costs, and increase customer satisfaction.

- Customer Satisfaction: Digital transformation allows you to offer personalized products and services, faster delivery, and better customer support.

- Competitive Advantage: Companies that adopt digital technologies are better positioned to compete in the marketplace.

In summary, digital transformation can help you increase efficiency, reduce costs, make better decisions, improve customer satisfaction, and gain a competitive advantage.

4. What If I Don’t Go for Digital Transformation?

Choosing not to embrace digital transformation can have serious consequences for your business:

- Lag Behind Competitors: Competitors who adopt digital technologies will likely outperform you in terms of efficiency, cost-effectiveness, and customer satisfaction. This could lead to a loss of market share.

- Higher Operating Costs: Without automation and digital tools, your operations may remain slow, inefficient, and prone to errors. This can lead to higher costs and lower profit margins.

- Less Operational Efficiency: If you ignore digital transformation, you may face less operation efficiency and less production speed.

- Customer Dissatisfaction: Today’s customers expect fast, personalized service and high-quality products. If you’re unable to meet these expectations, they may choose to do business with your competitors.

- Difficulty in Adapting to Change: As technology continues to evolve, businesses that don’t keep up may find it increasingly difficult to adapt to new trends and demands. This can result in missed opportunities and a decline in business performance.

- Missed Opportunities: Digital transformation can open up new revenue streams, such as offering products online through e-commerce or using data to develop new products. Without digital tools, you may miss out on these opportunities.

In essence, not going for digital transformation can put your business at a significant disadvantage, making it harder to compete, attract customers, and grow.

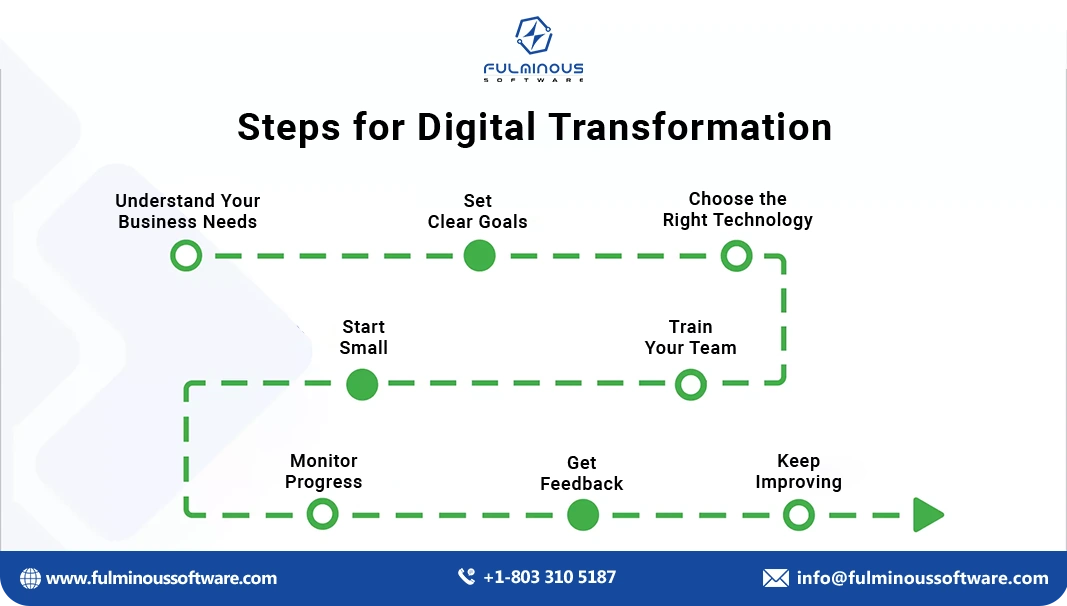

5. What Are the Steps for Digital Transformation?

Digital transformation can seem overwhelming, but breaking it down into steps makes it more manageable. Here’s a step-by-step guide:

- Understand Your Business Needs: Start by identifying the areas of your business that need improvement. For example, is your production process slow? Do you struggle with inventory management?

- Set Clear Goals: Once you’ve identified your business needs, set clear goals for your digital transformation.

- Choose the Right Technology: Research and select the technologies that will help you achieve your goals. For example, if your goal is to improve inventory management, you might consider implementing an inventory management system that uses real-time data.

- Train Your Team: Digital transformation involves more than just implementing new technology; it also requires training your team to use the technology effectively.

- Start Small: Begin with a small project or pilot program to test the new technology.

- Monitor Progress: Track the progress of your digital transformation efforts in each stage.

- Get Feedback: Involve your team and customers in the process by asking for their feedback.

- Keep Improving: Digital transformation is an ongoing process.

By following these steps, you can successfully navigate the digital transformation process and achieve your business goals.

6. How Much Do I Have to Spend on Digital Transformation?

The cost of digital transformation can vary depending on the size of your business, the type of technologies you choose, and the scope of the changes you want to make. Here’s what to consider:

Initial Costs:

- Equipment Purchase: This includes the cost of acquiring new machinery, devices, and other hardware required for digital transformation.

- Software Acquisition: Budgeting for the purchase or licensing of new software, such as ERP systems, CRM tools, or specialized manufacturing software.

- Technology Integration: Costs related to integrating new technologies with existing systems, which may include custom software development or APIs.

- Consultation Fees: Expenses for hiring experts or consultants to help design and plan the digital transformation strategy.

Implementation Costs:

- Installation and Setup: Costs for installing new equipment, software, and ensuring they work seamlessly within your current operations.

- Customization: Budgeting for the customization of software or hardware to meet your specific business needs.

- Testing and Debugging: Expenses related to testing new systems to ensure they function correctly and address any issues that arise.

- Employee Training: Costs for training staff on how to use new systems and technologies effectively.

Ongoing Costs:

- Software Updates: Regular updates to keep your software current, secure, and efficient, which may involve periodic fees.

- Maintenance and Support: Budget for ongoing maintenance of hardware and software, including potential support contracts.

- Subscription Fees: Recurring costs for cloud services, SaaS applications, or other digital tools that operate on a subscription basis.

- Training and Development: Continuous education and training for employees as new features or systems are introduced.

To manage costs effectively, create a budget that outlines both the initial and ongoing expenses. Choose affordable technology providers like Fulminous Software. Start with smaller projects to minimize risk and gradually invest in larger initiatives as your business grows.

7. How Much Will I Get Back From Digital Transformation?

The return on investment (ROI) from digital transformation can be substantial, depending on how effectively you implement it. Here’s what you can expect:

- More Profits: By improving efficiency and reducing costs, digital transformation can lead to higher profits.

- Fast Production: Digital transformation helps you to maximize the speed of production. More production means more clients and more business.

- Maximum Operational Efficiency: The features of the latest technology will boost your overall operation efficiency.

- More Customers: Digital transformation can help you attract more customers by improving product quality, offering personalized solutions, and providing better customer service.

- Better Reputation: Companies that adopt digital technologies are often seen as more innovative and reliable. This can enhance your reputation.

- Long-Term Growth: Digital transformation can position your business for long-term growth by making it more agile and responsive to market changes.

- Save Costs: When you choose digital transformation, you can cut down the costs of manual repetitive tasks.

The ROI may not be immediate, but the long-term benefits of digital transformation can far outweigh the initial costs. By investing in the right technology and processes, you can expect to see significant returns over time.

8. Who Will Assist Me with Digital Transformation?

Digital transformation is a complex process, but you don’t have to do it alone. Here’s who can help:

| Professionals | Type of Assistance |

|---|---|

| Digital Transformation Consultants | Expert advice to align digital transformation strategies with business objectives. |

| Project Managers | Oversees the digital transformation process from start to finish. |

| IT Support Specialists | Provides ongoing technical assistance to ensure digital transformation success. |

| Software Developers | Builds and customizes digital transformation solutions tailored to your needs. |

| Integration Specialists | Seamlessly connects new digital transformation tools with existing systems. |

| Data Analysts | Analyzes data to drive insights and optimize digital transformation processes. |

| Trainers & Educators | Educates your team on digital transformation technologies and tools. |

| Cybersecurity Experts | Implements measures to protect data during digital transformation. |

| Change Management Professionals | Assists in overseeing organizational modifications throughout the process of digital transformation. |

| Maintenance Engineers | Ensures continued performance of digital transformation systems with updates. |

It's better to choose an all-in-one partner like Fulminous Software!

It is always better to go with an experienced tech partner who can provide comprehensive solutions for your manufacturing businesses. Because hiring a separate team for each task may cost a huge price and make things more complex. Experienced Digital Transformation service providers like Fulminous Software provide all the solutions you need. At the same time, we have several offers that help you to access premium quality digital transformation solutions at a reasonable cost. Choosing the right tech partners and resources is crucial to achieving success in your digital transformation.

Other Benefits of Choosing Fulminous Software for Digital Transformation:

- Personalized Plans: We'll design a digital strategy that fits your business perfectly.

- Industry Insiders: We're experts in your manufacturing field.

- Seamless Integration: We'll add new systems without causing any problems to the current ones.

- Innovative Approach: We use the latest technology to drive your business forward.

- Agile Development: We can quickly adapt and deliver results.

- Ongoing Support and Long-lasting Partnership: We'll assist you throughout the process and keep long-term relationships with clients.

- Future-Proof Technology: Our solutions are designed to be adaptable.

- Enhanced Security: We prioritize data protection with strong security measures.

See Some Real Stories of Successful Digital Transformation

Nike - Digitalizing the Supply Chain

Challenge: Nike, a global sportswear giant, faced challenges related to ensuring ethical sourcing, reducing lead times, and improving supply chain visibility.

Solution: Nike implemented a digital supply chain platform that integrated data from various sources, including suppliers, manufacturers, and logistics providers. Key components of the platform included:

- Blockchain: To ensure transparency and traceability throughout the supply chain, particularly for ethical sourcing.

- Internet of Things: To monitor equipment operation and track the flow of commodities.

- Artificial intelligence: To optimize logistics routes, predict demand, and manage inventory levels.

Results: Nike's digital transformation led to:

- Improved sustainability: Blockchain technology enabled Nike to ensure ethical sourcing practices and reduce environmental impact.

- Reduced lead times: Optimized logistics and inventory management helped reduce lead times and improve responsiveness to market demand.

- Increased customer satisfaction: Faster delivery times and improved product quality enhanced customer satisfaction.

ABB - Leveraging Digital Transformation for Industrial Automation

Challenge: ABB, a global technology leader in electrification, industrial automation, and robotics, faced challenges related to improving operational efficiency, reducing costs, and staying competitive in a rapidly evolving industry.

Solution: ABB embraced digital transformation by implementing advanced technologies, including:

- Industrial Internet of Things (IIoT): ABB integrated sensors and data analytics into its industrial equipment to monitor performance, optimize maintenance, and improve efficiency.

- Robotics and automation: ABB expanded its robotics and automation offerings to help customers automate their manufacturing processes and improve productivity.

- Digital twin technology: ABB created digital twins of its equipment to simulate operations, identify potential issues, and optimize performance.

- Cloud-based solutions: ABB leveraged cloud computing to provide scalable and flexible solutions to its customers.

Results: ABB's digital transformation led to:

- Improved efficiency: ABB's IIoT and automation solutions helped customers improve their operational efficiency and reduce costs.

- Enhanced product innovation: ABB's digital twin technology enabled the development of innovative products and solutions.

- Increased competitiveness: ABB's focus on digital transformation positioned it as a leader in the industrial automation market.

- Sustainable operations: ABB's digital solutions helped customers reduce their environmental impact and improve sustainability.

Bosch - A Digital Transformation Leader in Automotive Manufacturing

Challenge: Bosch, a global supplier of automotive technology, faced challenges related to staying competitive in a rapidly evolving industry, improving product quality, and reducing costs.

Solution: Bosch implemented a digital transformation strategy that focused on:

- Connected vehicles: Bosch developed connected vehicle solutions, including advanced driver assistance systems, infotainment systems, and electric vehicle components.

- Industry 4.0: Bosch embraced Industry 4.0 principles, incorporating automation, data analytics, and connectivity into its manufacturing processes.

- Digital twin technology: Bosch created digital twins of its manufacturing facilities to optimize production, improve quality, and reduce costs.

- Sustainability: Bosch focused on developing sustainable products and reducing its environmental impact.

Results: Bosch's digital transformation led to:

- Product innovation: Bosch's focus on connected vehicles and advanced automotive technology positioned it as a leader in the industry.

- Improved efficiency: Industry 4.0 and digital twin technology helped Bosch improve manufacturing efficiency and reduce costs.

- Enhanced quality: Bosch's digital solutions enabled improved quality control and reduced defects.

- Sustainability: Bosch's focus on sustainability helped it meet growing consumer demand for environmentally friendly products.

Toyota - Leveraging Digital Transformation for Lean Manufacturing

Challenge: Toyota, a leading automotive manufacturer, faced challenges related to improving operational efficiency, reducing costs, and ensuring high-quality standards.

Solution: Toyota leveraged digital transformation to enhance its lean manufacturing principles, focusing on:

- Just-in-time (JIT) inventory: Toyota used digital tools to optimize its JIT inventory management, reducing waste and improving efficiency.

- Kaizen: Toyota implemented digital tools to support continuous improvement initiatives, such as Kaizen events.

- Andon: Toyota used digital andon systems to quickly identify and address production issues.

- Data analytics: Toyota used data analytics to analyze production data, identify areas for improvement, and optimize processes.

Results: Toyota's digital transformation led to:

- Improved efficiency: Toyota's lean manufacturing principles, enhanced by digital tools, helped improve operational efficiency and reduce waste.

- Reduced costs: Toyota's focus on cost reduction and continuous improvement resulted in significant cost savings.

- Enhanced quality: Toyota's quality management systems, supported by digital tools, helped ensure high-quality standards.

- Sustainable operations: Toyota's lean manufacturing practices and focus on efficiency contributed to sustainable operations.

Conclusion

A manufacturing company can increase productivity, maintain competitiveness, and provide customers with superior products by implementing digital transformation. Ask the right questions and take the right steps, and you can successfully navigate the digital transformation process and achieve your business goals.

Remember, digital transformation is not just about technology; it’s about rethinking how you do business in the digital age. Start small, plan carefully, and involve your team in the process. With the right approach — and a solid Digital Transformation Guide — it can take your business to the next level.

The success stories of leading manufacturing companies like Nike, ABB, Bosch, and Toyota are inspiring manufacturers to implement digital transformation as soon as possible.

If you are interested in implementing digital transformation in your manufacturing business, Contact us now!

FAQs

- Q1: What is digital transformation?

- A: Digital transformation involves updating your business with new technologies to improve operations, customer experience, and competitiveness in a fast-paced market.

- Q2: Why should manufacturers embrace digital transformation?

- A: Digital transformation enhances efficiency, reduces costs, improves customer satisfaction, and helps manufacturers stay competitive in the evolving industrial landscape.

- Q3: What are the key steps in digital transformation?

- A: Identify needs, set goals, choose technology, train teams, start small, monitor progress, gather feedback, and continuously improve processes.

- Q4: How does digital transformation improve efficiency?

- A: Automation, real-time data, and smart systems streamline processes, reduce errors, and increase production speed, leading to higher efficiency.

- Q5: What technologies are essential for digital transformation?

- A: Key technologies include cloud computing, AI, automation, IoT, and data analytics, all of which optimize operations and decision-making.

- Q6: What are the benefits of digital transformation for customers?

- A: Faster service, personalized products, improved quality, and better customer support enhance overall customer satisfaction and loyalty.

- Q7: How much does digital transformation cost?

- A: Costs vary based on business size, technology choices, and project scope, including initial setup, ongoing maintenance, and employee training.

- Q8: What is the ROI of digital transformation?

- A: ROI includes increased profits, improved efficiency, reduced costs, more customers, and long-term growth potential for your business.

- Q9: What happens if I don’t adopt digital transformation?

- A: Businesses risk falling behind competitors, facing higher operating costs, and struggling to meet customer expectations in a digital world.

- Q10: Who can help with digital transformation?

- A: Digital transformation consultants, IT specialists, and experienced tech partners like Fulminous Software can guide and support your journey.

HIRE A TOP SOFTWARE DEVELOPMENT COMPANY

Verified

Expert in Software & Web App Engineering

Verified

Expert in Software & Web App Engineering

I am Manish Kumawat, co-founder of Fulminous Software, a top leading customized software design and development company with a global presence in the USA, Australia, UK, and Europe. Over the last 10+ years, I am designing and developing web applications, e-commerce online stores, and software solutions custom tailored according to business industries needs. Being an experienced entrepreneur and research professional my main vision is to enlighten business owners, and worldwide audiences to provide in-depth IT sector knowledge with latest IT trends to grow businesses online

Partner with Top-Notch Web Application Development Company!

Discuss your Custom Application Requirements on info@fulminoussoftware.com or call us on +1-903 488 7170.

15 Days Risk-Free TrialRecommended Articles