Steps for Implementing Digital Transformation Successfully

Manish Kumawat

Last Updated on: 07 October 2025

The term ‘transformation’ in digital transformation itself shows that careful step-by-step implementation is necessary. It’s like giving your old house a complete makeover — you don’t just change the paint; you gut the place, replace outdated fixtures, and add modern amenities to truly implement digital transformation. That's essentially what digital transformation is for manufacturing businesses.

As several technologies, processes, and methods are involved in digital transformation, you need clear steps for implementing digital transformation. Digital transformation is all about renovation, replacing outdated systems and processes with new, tech-powered ones.

But unlike home renovations, digital transformation isn't just about aesthetics. It has several aspects to cover. Here we'll explore the steps involved in this digital transformation. Let's get started!

Digital Transformation in Manufacturing: Why It Matters

Digital transformation in manufacturing is like upgrading your business with the latest gadgets. How wonderful if you have a fridge that tells you when your milk is about to expire or a toaster that automatically adjusts to the perfect browning level? It's the same idea for factories. By using smart machines and software, factories can:

- Work faster: Machines can do repetitive tasks without getting tired or making mistakes.

- Make better stuff: With data, factories can figure out how to make things stronger, lighter, or cheaper.

- Save money: Less waste, fewer errors, and more efficient use of energy means big savings.

- Stay ahead: Customers love new and cool stuff, so digital factories can stay ahead of the competition.

Why following these steps is key to implementing digital transformation

What if you were trying to build a house without a blueprint? It would be difficult, right? The same goes for digital transformation. Following a structured approach helps ensure a smooth and successful journey.

Here's why:

- Avoid chaos: A plan keeps everyone on the same page and prevents wasted time and resources.

- Identify challenges early: By breaking down the process into steps, you can spot potential roadblocks before they become major problems.

- Measure progress: Each step is a milestone, allowing you to track your progress and make adjustments as needed.

- Maximize benefits: A well-thought-out plan helps you focus on the most important areas, ensuring you get the most out of your digital transformation efforts.

Therefore, although it could be tempting to jump right in, it's better to take small steps and develop a solid foundation for your digital future.

The Risks of Skipping Steps in Implementing Digital Transformation

Yes! Skipping implementing digital transformation steps can lead to significant risks.

Without a well-defined strategy, you may invest in technologies or projects that don't align with your business goals, leading to wasted time and money. A lazy approach can result in unexpected challenges, delays, and costly rework, ultimately increasing the overall cost of your digital transformation.

Planning ahead will help you avoid operational hindrances and boost employee morale and productivity. Measuring progress and making sure your digital transformation efforts are producing the expected results are challenging without a clear strategy.

In today's fast-paced business environment, companies that fail to implementing digital transformation effectively risk falling behind their competitors. Thus, for a successful digital transformation journey, adhering to an organized method is essential.

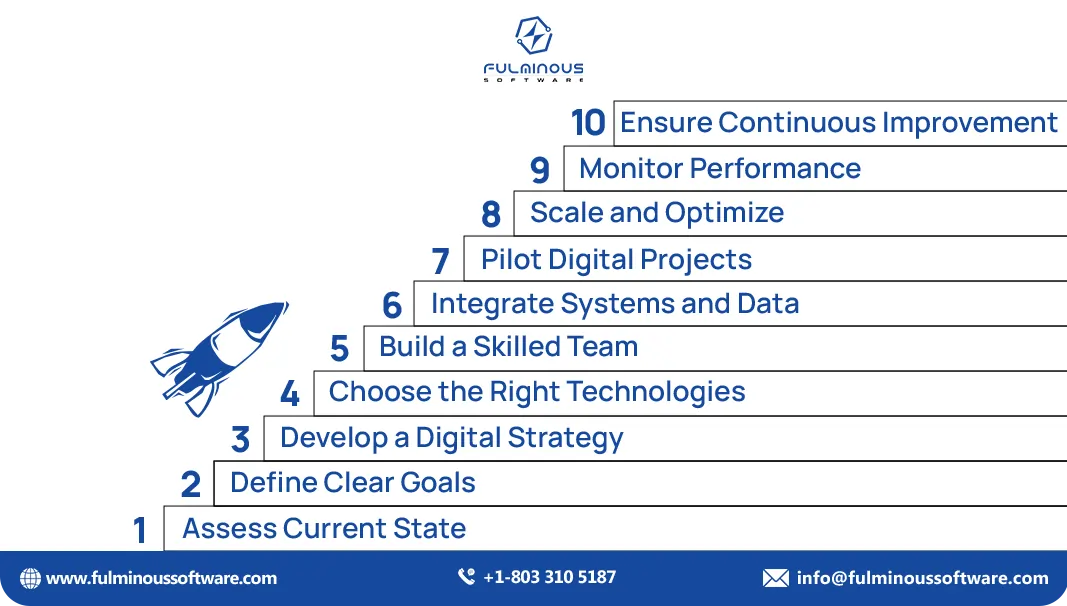

10 Ideal Steps to Implementing Digital Transformation

To successfully implement digital transformation, you need to do it the right way. Let's go through 10 steps to help you do this.

STEP 1: Assessing Your Manufacturing Reality: The First Step to Digital Success

Think of your manufacturing digitalization process as a big puzzle. Before you can start adding fancy new pieces (like digital technology), you need to understand what you already have.

Why is it important?

- Identifying Gaps: Knowing where you stand helps you figure out what's missing or not working as well as it should.

- Setting Realistic Goals: You can't aim for the stars if you don't know where you're starting from.

- Prioritizing Investments: Knowing your pain points helps you focus on the areas that will give you the biggest bang for your buck.

- Building a Roadmap: Once you know where you are, you can plan the best route to where you want to be.

How to Assess Your Current State:

- Take Inventory: List all your current equipment, software, and processes.

- Talk to the People: Ask your employees about their daily challenges and what they think could be improved.

- Analyze Data: Look at your production data to identify trends, bottlenecks, and inefficiencies.

- Benchmark: Compare your performance to industry standards to see where you stand.

Remember: Assessing your current state isn't about finding fault. It's about gathering information to make informed decisions and build a stronger, more efficient manufacturing operation.

STEP 2: Setting the Stage for Digital Success: Defining Clear Goals

Once you've got a good understanding of your current manufacturing process, it's time to decide your goals.

Why are goals important?

- Focus: Goals give your digital transformation a direction, preventing you from getting lost in a sea of possibilities.

- Motivation: Having something to strive for can boost morale and keep everyone motivated. Measureme

- Measurement: Goals provide a way to measure progress and ensure you're on track.

- Alignment: Clear goals help ensure that everyone in your organization is working towards the same objectives.

How to define clear goals:

- Be Specific: Instead of saying "improve efficiency," try "reduce production time by 15%."

- Be Measurable: Make sure you can quantify your goals so you can track progress.

- Be Achievable: Set goals that are challenging but realistic.

- Be Relevant: Ensure your goals align with your overall business strategy.

- Be Time-bound: Set specific deadlines to be punctual.

Remember: Your goals should be ambitious but achievable. Think of your goals as the destination you're aiming for on your digital transformation journey.

STEP 3: Crafting Your Digital Blueprint: Developing a Strategy

Now that you know where you're starting from and where you want to go, it's time to map out the journey. Without a strategy, you may wander here and there. Strategies are relevant to save time, effort, and wealth.

Why is a strategy important?

- Roadmap: A strategy provides a clear path to follow, ensuring you don't get sidetracked.

- Investment: It helps you prioritize investments and allocate resources effectively.

- Alignment: A strategy ensures that your digital initiatives are aligned with your overall business goals.

- Risk Management: By anticipating potential challenges, you can develop strategies to mitigate them.

How to develop a digital strategy:

- Identify Key Areas: Determine which areas of your manufacturing process will benefit most from digital transformation.

- Choose Technologies: Research and select the technologies that best suit your needs and goals.

- Prioritize Initiatives: Decide which digital projects to tackle first, based on their potential impact and feasibility.

- Consider the People Factor: Don't forget about the human element. Plan for training, change management, and employee engagement.

- Build a Timeline: Plan out when you want to execute your digital projects.

Remember: An adaptive and flexible digital strategy is essential. As technology evolves and your business needs change, you may need to adjust your plan accordingly.

STEP 4: Picking the Perfect Tools for the Job: Choosing the Right Technologies

Once you've mapped out your digital journey, it's time to pick the tools you'll need. This is where choosing the right technologies comes in.

Why is technology important?

- Efficiency: The right technology can streamline processes and boost productivity.

- Innovation: New technologies can open up new growth opportunities.

- Competitive Advantage: By adopting cutting-edge technology, you can gain a competitive edge in the marketplace.

How to choose the right technologies:

- Assess Your Needs: Identify the specific problems you want to solve or the goals you want to achieve.

- Research Options: Explore the available technologies and their capabilities.

- Consider Cost: Evaluate the cost of implementing digital transformation, maintenance, and ongoing support.

- Think Scalability: Choose technology that will expand with your company.

- Prioritize Security: Ensure that the technologies you select have robust security features.

Remember: Technology is just a tool. It's how you use it that matters. Choose technologies that align with your digital strategy and support your overall business objectives.

STEP 5: Building Your Digital Dream Team: Hiring a Skilled Tech Team

You have the goals, the tools, and the strategy. Now, you need the people to make it all happen.

Why is a skilled tech team important?

- Expertise : Identify the specific problems you want to solve or the goals you want to achieve.

- Problem-Solving: A good team can troubleshoot issues and find innovative solutions.

- Adaptability: They can change to meet evolving business needs and technological changes.

- Collaboration: A strong tech team can work effectively with other departments to ensure a smooth digital transformation.

How to hire a skilled tech team:

- Define Roles: Clearly outline the specific skills and experience you need in your team.

- Source Candidates: Use a variety of channels, including job boards, referrals, and social media.

- Conduct Interviews: Ask questions that assess technical skills, problem-solving abilities, and cultural fit.

- Technical Assessments: Consider conducting technical assessments or coding challenges to evaluate candidates' skills.

Remember: A skilled tech team is more than just a group of individuals. They're a valuable asset that can help you achieve your digital transformation goals.

STEP 6: Bringing Systems and Data Together: Connecting the Dots

Imagine your manufacturing process as a puzzle. Every component symbolizes a distinct system or data set. To get a complete picture, you need to connect all the pieces together. That's where integrating systems and data comes in.

Why is integration important?

- Efficiency: By connecting different systems, you can streamline processes and reduce manual tasks.

- Visibility: Integration provides a comprehensive view of your operations, helping you identify bottlenecks and areas for improvement.

- Decision-Making: Access to real-time data can support better decision-making.

How to integrate systems and data:

- Assess Your Systems: Identify the systems you want to integrate and their capabilities.

- Choose an Integration Platform: Select a platform that can connect different systems and data sources.

- Develop an Integration Plan: Outline the specific data flows and processes you want to integrate.

- Address Data Quality: Ensure that the data you're integrating is accurate, consistent, and up-to-date.

- Test and Optimize: Thoroughly test your integrations and make adjustments as needed.

Remember: Integration is an ongoing process. As your systems and data evolve, you may need to update your integration plans.

STEP 7: Testing the Waters: Piloting Digital Projects

Before diving into a full-scale digital transformation, it's a good idea to test at a minor level first.

Why pilot digital projects?

- Risk Mitigation: Piloting helps you identify and address potential challenges before they become major problems.

- Learning: You can learn from the experience and make adjustments to your digital strategy.

- Gain Buy-In: Successful pilots can help build support for your digital transformation initiatives.

- Phased Implementation: Piloting allows you to implement digital transformation gradually, minimizing disruption to your operations.

How to pilot digital projects:

- Choose a Pilot: Select a project that is relatively small in scope but still offers significant potential benefits.

- Set Clear Objectives: Define the specific goals you want to achieve with the pilot.

- Assemble a Team: Build a team that has the knowledge and experience needed to carry out the pilot.

- Implement the Project: Follow your digital strategy and carefully monitor the pilot's progress.

- Evaluate Results: Assess the pilot's success or failure and learn from the experience.

Remember: Piloting is not about perfection. It's about learning, adapting, and improving.

STEP 8: Taking Your Digital Success to New Heights: Scaling and Optimizing

Once you've successfully piloted your digital projects, it's time to expand their reach and maximize their benefits. That's where scaling and optimizing come in.

Why scale and optimize?

- ROI: By scaling successful initiatives, you can increase their return on investment.

- Efficiency: Optimization helps you refine your processes and improve performance.

- Innovation: As you scale and optimize, you can identify new opportunities for innovation.

- Competitive Advantage: By staying ahead of the curve, you can maintain a competitive edge in the marketplace.

How to scale and optimize:

- Evaluate Performance: Assess the performance of your scaled-up initiatives and identify areas for improvement.

- Optimize Processes: Refine your processes to eliminate bottlenecks and increase efficiency.

- Leverage Data: Use data analytics to identify trends and make data-driven decisions.

- Adapt to Change: Be ready to modify your strategies as commercial requirements and technological advancements take place.

Remember: Scaling and optimizing an ongoing process. It's about continuously refining your digital initiatives to achieve maximum value.

STEP 9: Keeping an Eye on the Prize: Monitoring Performance

Once you've scaled and optimized your digital initiatives, it's important to keep track of their performance. That's where monitoring comes in.

Why monitor performance?

- Identify Trends: Monitoring helps you spot trends and patterns in your data.

- Measure ROI: You can track the return on investment of your digital initiatives.

- Identify Issues: Monitoring can help you detect problems early and address them before they become major issues.

- Continuous Improvement: By analyzing performance data, you can identify areas for improvement and make data-driven decisions.

How to monitor performance:

- Define Key Performance Indicators (KPIs): Find out the key performance indicators for your company.

- Collect Data: Gather data from your systems and processes.

- Analyze Data: Use data analytics tools to analyze your data and identify trends.

- Visualize Data: Create dashboards and reports to visualize your data and make it easy to understand.

Remember: Monitoring performance is an ongoing process. It's important to regularly review your KPIs and adjust your monitoring approach as needed.

STEP 10: Always Striving for Better: Ensuring Continuous Improvement

Digital transformation is a process that needs continuous monitoring and improvement. Maintaining your market position demands creating a culture of continuous improvement.

Why is continuous improvement important?

- Adaptability: A culture of continuous improvement helps you adapt to changing market conditions and technological advancements.

- Innovation: By constantly seeking ways to improve, you can foster a culture of innovation and creativity.

- Efficiency: Continuous improvement can help you streamline processes and reduce costs.

- Customer Satisfaction: By delivering better products and services, you can improve customer satisfaction.

How to ensure continuous improvement:

- Foster a Learning Culture: Encourage employees to learn new skills and share their knowledge with others.

- Set Ambitious Goals: Set challenging but achievable goals that inspire your team.

- Encourage Experimentation: Create a safe environment where employees can experiment and try new things.

- Measure Progress: Track your progress towards your goals and celebrate successes.

- Seek Feedback: Continually ask stakeholders, including staff and clients, for their opinions.

Remember: Continuous improvement is a mindset. It's about always striving for better, regardless of your current level of success. By embracing a culture of continuous improvement, you can ensure that your digital transformation journey is a long-lasting success.

Join the Digital Revolution with Fulminous Software

When you're renovating your home, what if you could try to do it all yourself? It's probably going to be a lot of work, and you might not get the best results. That's why it's often better to hire a professional contractor. There are various workers, like electricians, plumbers, carpenters, and so on, in their team for specific work.

It's the same with digital transformation. First of all, accept the reality that It can be stressful and time-consuming to try to handle everything on your own. That's where leading tech companies like Fulminous come in.

Why choose Fulminous Software to implement digital transformation

Experts: They know their stuff when it comes to technology.

Experience: They've helped countless businesses like yours succeed.

Custom Solutions: They can tailor their solutions to fit your specific needs.

Innovative Approach: Using cutting-edge technology to continuously push beyond the boundaries and provide innovative solutions.

Client-Centric Focus: Your business objectives and difficulties are taken into consideration when designing each project.

Smooth Collaboration: To guarantee efficient execution and ongoing communication, collaborate closely with your team.

Fulminous Software's team of experts is well-versed in a wide range of cutting-edge fields, including:

- Manufacturing Website Development: They can create stunning and functional websites that showcase your manufacturing capabilities and attract new customers.

- Industrial IoT: Fulminous can help you leverage IoT technology to optimize your manufacturing processes, improve efficiency, and reduce costs.

- AI Integration: Their AI experts can help you integrate artificial intelligence into your manufacturing operations, enabling you to make smarter decisions and automate tasks.

- Robotics: Fulminous can assist you in implementing digital transformation by introducing robotics solutions to automate repetitive tasks, improve safety, and increase productivity.

- Automation: Their team can help you automate various aspects of your manufacturing processes, from production to quality control.

- Machine Learning (ML): Fulminous can leverage ML algorithms to analyze data, predict trends, and optimize your manufacturing operations.

When you work with Fulminous, you get more than simply a tech company—you get a trustworthy partner who can assist you in realizing your digital manufacturing objectives.

Conclusion

In short, implementing digital transformation is more than just buying new tech. It's about making your business future-ready in multiple dimensions. But before investing in manufacturing digitalization, clearly follow the above-described steps. By following the right steps and having the right help, you can make it happen smoothly. It is better to follow the deal steps one by one rather than going ahead blindly.

Fulminous Software can help you with this. We're experts in helping manufacturing businesses use new technology. We can help you make your business more efficient and successful.

Don't wait! Start your manufacturing digitalization journey today and see the benefits for yourself. Let's make your business the top! Contact us

FAQs

- Q1: What is digital transformation in manufacturing?

- A: Digital transformation in manufacturing is the integration of advanced technologies to optimize production, efficiency, and innovation.

- Q2: Why is digital transformation important for manufacturers?

- A: It improves operational efficiency, reduces costs, enhances product quality, and keeps manufacturers competitive in a digital-driven world.

- Q3: How does IoT help in manufacturing?

- A: IoT connects devices, enabling real-time monitoring, predictive maintenance, and automation, leading to reduced downtime and increased productivity.

- Q4: What are the benefits of adopting AI in manufacturing?

- A: AI enhances decision-making, automates repetitive tasks, improves production accuracy, and helps with predictive maintenance.

- Q5: How can manufacturers start their digital transformation journey?

- A: Manufacturers should assess current systems, set goals, and invest in the right technologies like IoT, AI, and automation tools.

- Q6: What role does data analytics play in manufacturing?

- A: Data analytics helps manufacturers identify patterns, optimize processes, predict equipment failures, and improve overall operational efficiency.

- Q7: How does automation improve manufacturing processes?

- A: Automation increases production speed, reduces human errors, improves safety, and allows for the efficient handling of repetitive tasks.

- Q8: How can cloud computing benefit manufacturing companies?

- A: Cloud computing enables remote access to data, scalability, real-time collaboration, and cost-effective infrastructure management.

HIRE A TOP SOFTWARE DEVELOPMENT COMPANY

Verified

Expert in Software & Web App Engineering

Verified

Expert in Software & Web App Engineering

I am Manish Kumawat, co-founder of Fulminous Software, a top leading customized software design and development company with a global presence in the USA, Australia, UK, and Europe. Over the last 10+ years, I am designing and developing web applications, e-commerce online stores, and software solutions custom tailored according to business industries needs. Being an experienced entrepreneur and research professional my main vision is to enlighten business owners, and worldwide audiences to provide in-depth IT sector knowledge with latest IT trends to grow businesses online.

Partner with Top-Notch Web Application Development Company!

Discuss your Custom Application Requirements on info@fulminoussoftware.com or call us on +1-903 488 7170.

15 Days Risk-Free TrialRecommended Articles