Understanding the Digital Transformation Model

Manish Kumawat

Last Updated on: 07 October 2025

Everything around us is becoming digital in the current scenario. We have been seeing huge changes in how we communicate, shop, work, and how businesses operate. Even though we are going to discuss digital transformation in the manufacturing sector, this transformation is visible everywhere. It is more than just a technical term – it’s a powerful process that helps businesses improve their operations, services, and even their overall culture with the assistance of trending technologies. This is where a well-structured Digital Transformation Model plays a crucial role in guiding organisations through this shift effectively.

First of all, let’s see the two major terms we are going to discuss:

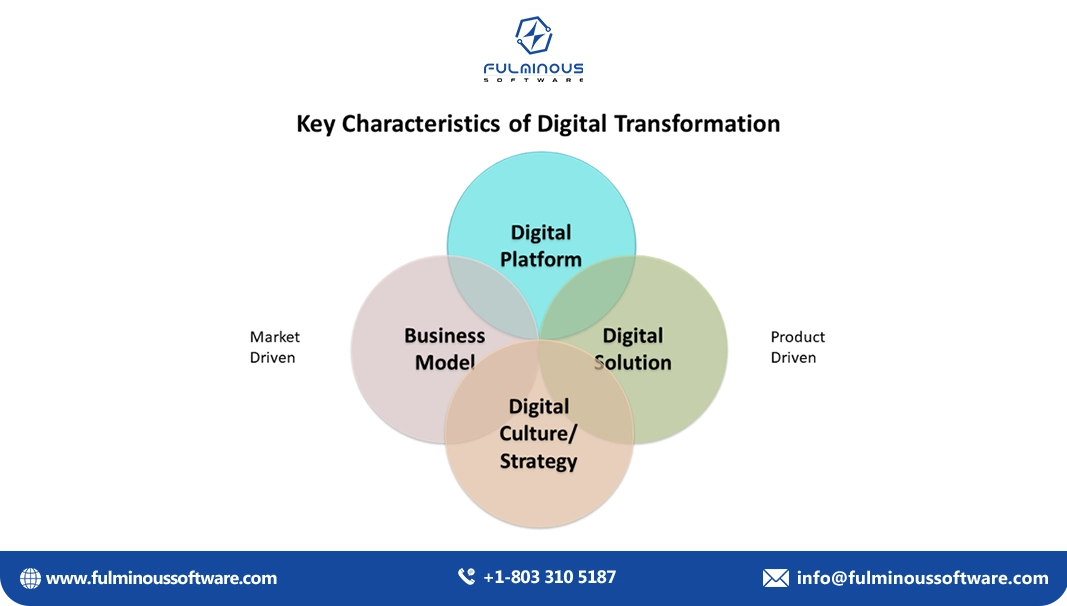

Digital Transformation

The process of using digital technologies to change how businesses operate can be referred to as digital transformation. Digital transformation is not only just about adding or using new technology; it’s about rethinking the way businesses do everything.

Digital Transformation Model

Think of building a house. You need a plan, right? A digital transformation model is like that plan for your business. It helps you find out how to use technology to make your manufacturing business better. It's like a well-defined guide that tells you what to do and when.

The digital transformation model helps you choose the right manufacturing tools and techniques. It also makes sure everything works together smoothly. You can use it to focus on the most important things and make sure your business is successful in the long run.

The meaning of these terms reveals the huge benefits of adapting them. We know that you are excited. So here we will discuss the digital transformation model in depth including its importance, types, models, examples, factors, and challenges.

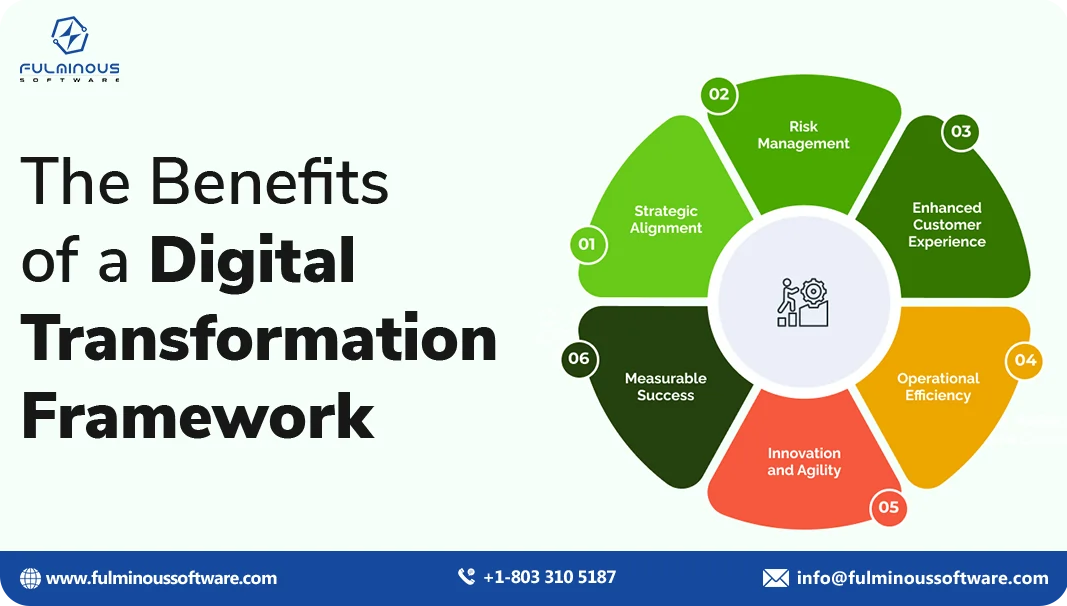

Importance of Digital Transformation Models

Digital transformation models are crucial for manufacturing businesses because they simplify the complex process of change. Here’s how they help manufacturers:

- Set Clear Goals: They help manufacturing businesses define objectives and prioritize tasks for a smooth transformation.

- Improve Processes: They identify and improve workflows, making it easier for manufacturers to adopt new technologies.

- Reduce Risks: They help manufacturing businesses predict problems and plan solutions effectively.

- Specially For Your Business: They create customized plans for manufacturers and the manufacturing industry.

- Monitor Progress: Manufacturing businesses easily measure success and evaluate the results of digital changes.

- Boost Teamwork: Collaboration across departments in manufacturing businesses is another key benefit.

In short, these models serve as a guide to ensure manufacturers achieve a focused and effective digital transformation.

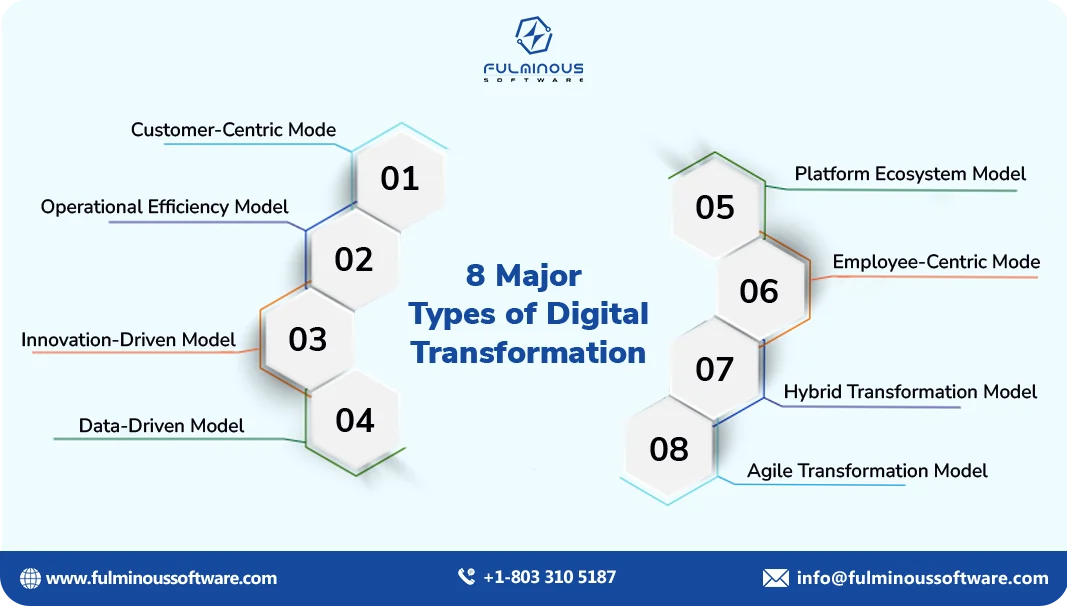

8 Major Frameworks for Digital Transformation

There are several types of digital transformation models. Here we will see each in detail.

1. Customer-Centric Model

The name of the model itself says that the customer is the center of focus in this model. Improving the overall experiences of customers is the goal of this transformation model. Here technologies like data analytics, artificial intelligence (AI), and personalized tools are used for this purpose.

Customer data including what they want, how they behave, and what problems they face are deeply studied through these data. After that, they use this information to provide better services or products. The main goal is to make manufacturing customers feel valued and understood.

For example:

- Online stores use AI to recommend items based on your previous purchases.

- Banking businesses use chatbots to answer questions quickly and offer services for customers.

A customer-centric digital transformation model can help manufacturers create products that meet specific customer demands or offer personalized after-sales services.

2. Operational Efficiency Model

The Operational Efficiency Model of digital transformation mainly targets faster and smarter business processes. Automating tasks, saving time, and cutting costs can be achieved by this model.

The operational Efficiency Model mainly uses tools like Enterprise Resource Planning (ERP) systems and the Internet of Things (IoT) for manufacturing businesses. Manufacturers track production, monitor machines, and reduce waste with this.

For example:

- A manufacturer can use sensors to check if a machine is about to break down and fix it before it causes delays.

- ERP systems are best to manage inventory and orders, making operations smooth.

- Reducing errors is another key in this model because machines follow programmed instructions more accurately than humans.

Efficient production, higher-quality goods, saving maximum money, and delivering products faster to customers can be achieved by this.

3. Innovation-Driven Model

The Innovation-Driven Model deals with using the latest and trending technologies to create new products or services. Advanced technologies like artificial intelligence (AI), 3D printing, and blockchain can be the main driving force in this model of digital transformation. Manufacturers can make unique and profitable products.

For example:

Innovation-driven mode encourages manufacturing businesses to be the leader in the industry with unique and custom products. It’s not just about improving what already exists but inventing entirely new solutions. Manufacturing businesses can open new markets and attract large numbers of customers using this.

4. Data-Driven Model

The name itself defines this model as all about available data. The Data-Driven Model helps businesses make the best and most profitable decisions. The data-based model uses advanced tools like data analytics and machine learning. Manufacturing businesses collect data from machines, sensors, and production lines. Manufacturers use this information to improve efficiency and solve problems.

For example:

- A manufacturer can analyze data to find which machines are slowing down production.

- Logistics businesses use data to plan faster delivery routes.

- In healthcare, data helps track patient health trends and improve treatments.

The Data-Driven Model of digital transformation is the best solution for manufacturers to predict future trends, reduce waste, and make their operations smarter. It’s about using available information to make maximum profits.

5. Platform Ecosystem Model

The Platform Ecosystem Model connects different people or businesses through a shared platform. Manufacturers can improve communication, reduce delays, and offer better services by using platforms. It’s about creating a space where everyone benefits from working together.

For example:

- Think of Uber, which connects drivers and passengers, or Salesforce, which helps companies manage customer relationships.

In manufacturing, a platform might connect suppliers, manufacturers, and customers. For example, a system can allow suppliers to update inventory levels, manufacturers to place orders, and customers to track shipments. This type of model ensures everyone involved works together smoothly.

6. Hybrid Transformation Model

The combination of both digital and traditional methods is a hybrid model. In manufacturing, a hybrid digital transformation model helps remove differences between old systems and new technologies.

For example:

- Using augmented reality (AR) to train workers while still maintaining hands-on practices.

- Using AR to guide assembly line workers in real-time, reducing errors.

At the same time, manufacturers continue using physical tools and machines. This model ensures a smooth transition to digital while keeping what works from traditional methods. By blending the best of both worlds, manufacturers can improve efficiency and reduce the risks of going fully digital too quickly.

7. Employee-Centric Model

The Employee-Centric Digital Transformation Model focuses on making work easier and better for employees. Collaborative software, online training, and HR analytics are the major technologies used in this model.

For example:

- Manufacturers can use apps to schedule shifts or training programs to teach workers new skills.

It’s a fact that happy employees will be more productive. Manufacturers can help their teams work efficiently and feel more satisfied. This also reduces errors and improves teamwork. Investing in employees ensures manufacturers have a skilled and motivated workforce. This model shows that businesses grow when their people grow.

8. Agile Transformation Model

The Agile Digital Transformation Model helps manufacturing businesses cope with changes easily. It uses flexible methods like DevOps and scalable cloud solutions. For manufacturers, this might mean rapidly adjusting production schedules or adopting new technologies without disrupting operations.

For example:

- If demand for a product suddenly increases, an agile system can help manufacturers increase production.

This model ensures businesses stay responsive and efficient, even in unpredictable situations. By staying flexible, manufacturers can handle challenges and seize new opportunities faster than competitors. It’s all about being ready for anything.

5 Digital Transformation Model Examples

There are plenty of businesses that succeeded by choosing a suitable digital transformation model. Here we will see the major 5 businesses.

Customer-Centric Model of Amazon

Amazon is one of the best examples of companies that make customers happy with the help of trending smart technology. They use artificial intelligence (AI) to understand what customers like.

When you shop online, Amazon suggests items based on your previous searches and purchases. They also use predictive analytics to figure out what people might need in the future. This helps Amazon stock the right products in the right places.

Amazon has a strong delivery system, which makes sure packages arrive quickly and safely. They track every order closely, so customers always know when to expect their items. This focus on fast and personalized service is why many people trust and enjoy shopping with Amazon. That’s why Amazon has become one of the biggest and most trusted online stores in the world.

Tesla’s Innovation-Driven Model

Tesla is known for creating new and exciting technology. They make electric cars that are good for the environment and fun to drive. Tesla uses the Internet of Things (IoT) to connect their cars to the internet. This allows cars to update themselves with new software, just like a smartphone.

They also use AI to make self-driving cars a reality. Tesla cars can learn from the roads they drive on and improve over time. Automation in Tesla factories helps build cars faster and with fewer mistakes. Tesla has become a leader in the electric vehicle industry by focusing on innovation.

GE’s Operational Efficiency Model

General Electric (GE) focuses on working smarter and saving resources. They use IoT and big data to keep machines running smoothly. For example, sensors on their equipment collect data about how the machines are working. This helps GE predict when a machine might need fixing, so it doesn’t break down unexpectedly.

This approach is called predictive maintenance. It saves time and money because repairs are done before problems become serious. GE uses this system in industries like energy and manufacturing, where efficiency is very important. GE helps businesses produce more while using fewer resources.

Netflix’s Digital-First Model

Netflix focuses on digital technology to deliver entertainment. They use cloud computing to stream shows and movies to millions of people around the world. This means you can watch Netflix anytime, anywhere, as long as you have an internet connection.

Netflix also uses AI to recommend shows and movies you might like based on what you’ve already watched. This personalized experience keeps users coming back. The company relies on data analytics to understand what content is popular and what isn’t, helping them make better decisions about what to offer. Netflix has become a global leader in online entertainment by focusing on digital tools.

Microsoft's Hybrid Transformation Model

Microsoft combines old and new ways of working to help businesses succeed. They offer traditional software like Microsoft Office along with modern cloud services like Azure. Azure allows businesses to store and access data online, making work more flexible and efficient.

This mix of tools helps companies move to digital systems without giving up the tools they’re used to. For example, a business can use both cloud-based tools and software installed on their computers. Microsoft also helps companies with digital training, so employees can use new technologies easily. Microsoft makes it easier for businesses to adapt to the modern world by blending traditional and digital solutions.

Factors for Choosing a Digital Transformation Model

Before you choose a digital transformation model for your business, you need to consider the following points:

- Business Objectives: You must think about what your manufacturing business wants to achieve. For that, ask the following question: Do you want to work faster, make customers happier, or come up with new ideas? Knowing your short- and long-term goals helps you pick the right model.

- Industry Needs: Every industry has its own challenges. Always choose a model that solves the problems in your industry and makes your work easier. For example, manufacturers might need tools for predictive maintenance to keep machines running smoothly.

- Technological Readiness: Look at the technology your manufacturing business uses now. Are you ready to add new tools like cloud storage, AI, or smart devices? If not, you might need to upgrade your systems first.

- Budget and Resources: Check how much money and how many people you have to help with the transformation. Some models need more investment, while others might fit a smaller budget.

- Employee Expertise: Think about your team’s skills. Are they ready to use new tools, or will they need training? If your team isn’t familiar with the technology, you might need to hire experts or provide learning opportunities to help them succeed.

- Customer Expectations: Understand what your customers want. Choose a model that helps you meet these needs so your customers stay happy and loyal.

- Risk Management: Think about the risks involved in digital transformation. A good model will include steps to handle these risks.

- Timeframe: Decide how quickly you need the changes to happen. If you need results fast, choose a model that focuses on speed. If you have more time, you can pick a model that works step by step for a thorough transformation.

- Measurements of Success: You need a clear decision on how you will measure success. Make sure you have metrics to track your progress and where you need to be better.

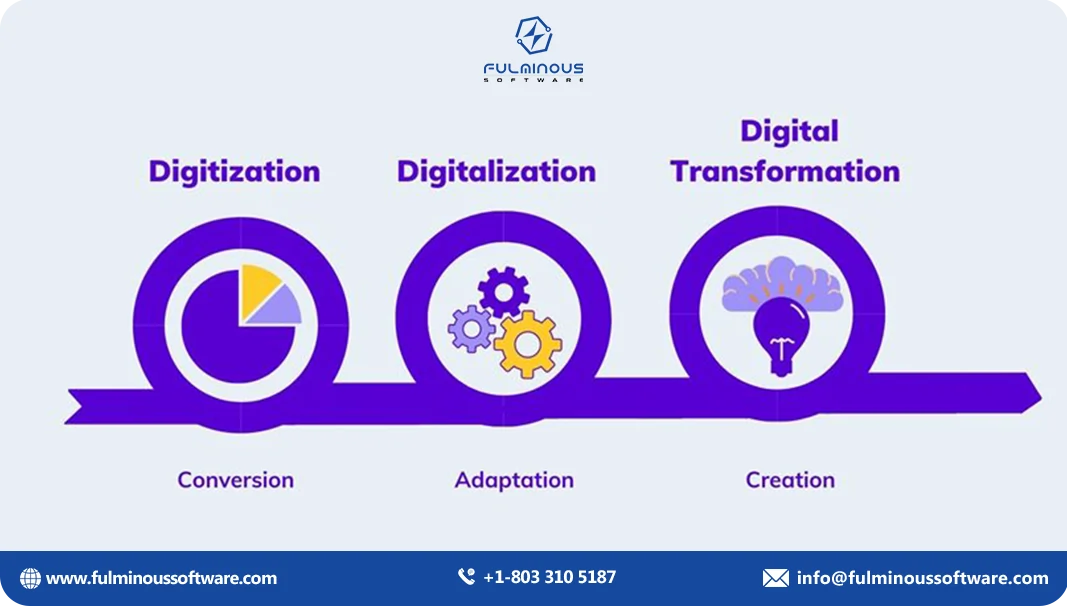

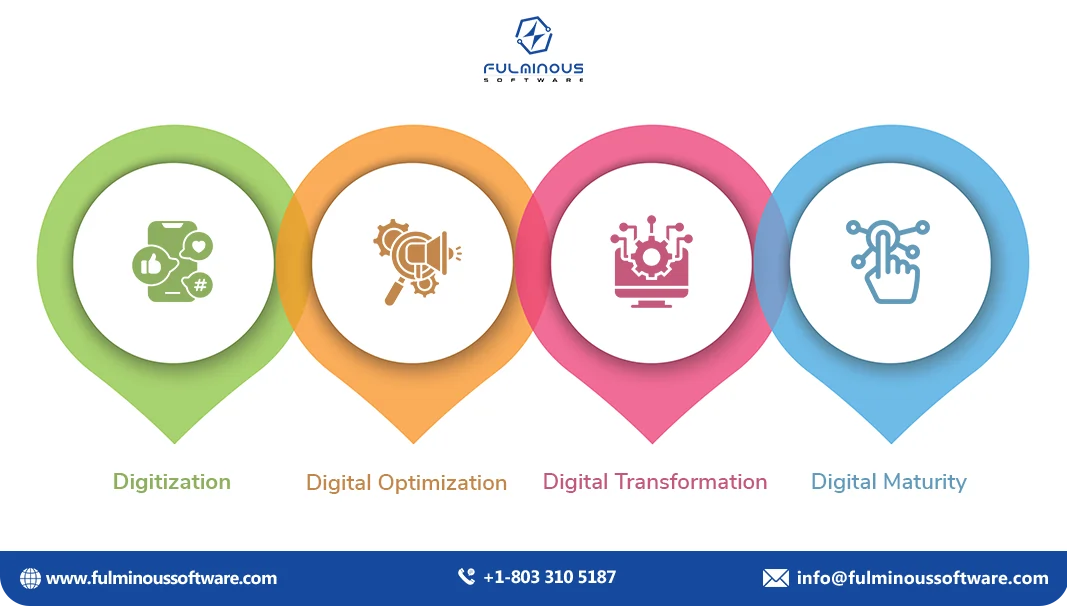

Stages of Digital Transformation

When you go ahead in the digital transformation of y our manufacturing business, the awareness about stages of digitalization will be useful for you.

Digitization

Digitization is about turning paper-based or manual work into digital forms. For example, scanning a paper document to make it a PDF is digitization. It also includes automating simple tasks, like setting up a computer to send reminders instead of writing them by hand. This stage makes it easier to store and share information.

Digital Optimization

Optimization of digital functions deals with using digital tools to improve how things work. For example, a company might use software to speed up order processing or track shipments better. Instead of changing everything, this stage focuses on making small improvements.

Digital Transformation

Digital transformation is a big change in how a business works. It’s not just about using technology—it’s about changing the way employees work, how customers are served, and how the company runs. For example, a store might start selling products online or use apps to track deliveries.

Digital Maturity

Digital maturity happens when a business is fully comfortable with using digital tools. At this stage, they don’t just use technology—they keep improving it. For example, a factory might use smart machines that learn and get better over time.

Conclusion

If you are a manufacturing business owner, you might have understood the need to add digital transformation. The above information shows digital transformation can’t be considered just as using new technology. It covers the changes in your business process in all dimensions.

At the same time, you need to consider the above-discussed factors while choosing digital transformation. There are several businesses like Netflix, Tesla, GE, Amazon, and Microsoft that have implemented the right digital transformation model. Their success stories in the industry help them to be a real inspiration for you.

By passing through digitization, digital optimization, and digital transformation, you need to reach digital maturity. The digital maturity of your manufacturing business can make you the leader in your industry. It’s necessary to survive and succeed in a manufacturing world that depends on technology.

Top digital transformation service providers like Fulminous Software can assist you even in choosing and implementing digital transformation models. If you want to succeed in the manufacturing business with a perfect digital transformation model, contact us now!

FAQs

- Q1: What is a digital transformation model?

- A digital transformation model is a simple plan that helps businesses use new technology step by step.

- Q2: How does the customer-centric model help manufacturers?

- It makes customers happy by using tools like AI to learn what they like and give them special products or services.

- Q3: What is the role of data in digital transformation?

- Data helps make better choices, find problems, and guess future trends to improve manufacturing.

- Q4: How does the operational efficiency model help manufacturers?

- It uses tools like IoT to make work faster, fix mistakes, and organize tasks better.

- Q5: What tools drive innovation in digital transformation?

- Tools like AI, 3D printing, and blockchain help create new ideas and stay ahead of others.

- Q6: What is the hybrid transformation model?

- It mixes old methods with digital tools like AR to change smoothly and effectively.

- Q7: What industries use the digital-first model?

- Industries like online shopping, factories, and banks use digital tools to work faster and smarter.

- Q8: What problems do manufacturers face in digital transformation?

- They face high costs, need skilled workers, and find it hard to fit new tools into old systems.

HIRE A TOP SOFTWARE DEVELOPMENT COMPANY

Verified

Expert in Software & Web App Engineering

Verified

Expert in Software & Web App Engineering

I am Manish Kumawat, co-founder of Fulminous Software, a top leading customized software design and development company with a global presence in the USA, Australia, UK, and Europe. Over the last 10+ years, I am designing and developing web applications, e-commerce online stores, and software solutions custom tailored according to business industries needs. Being an experienced entrepreneur and research professional my main vision is to enlighten business owners, and worldwide audiences to provide in-depth IT sector knowledge with latest IT trends to grow businesses online.

Partner with Top-Notch Web Application Development Company!

Discuss your Custom Application Requirements on info@fulminoussoftware.com or call us on +1-903 488 7170.

15 Days Risk-Free TrialRecommended Articles