Top Trends in Digital Transformation for Manufacturing

Manish Kumawat

Last Updated on: 07 October 2025

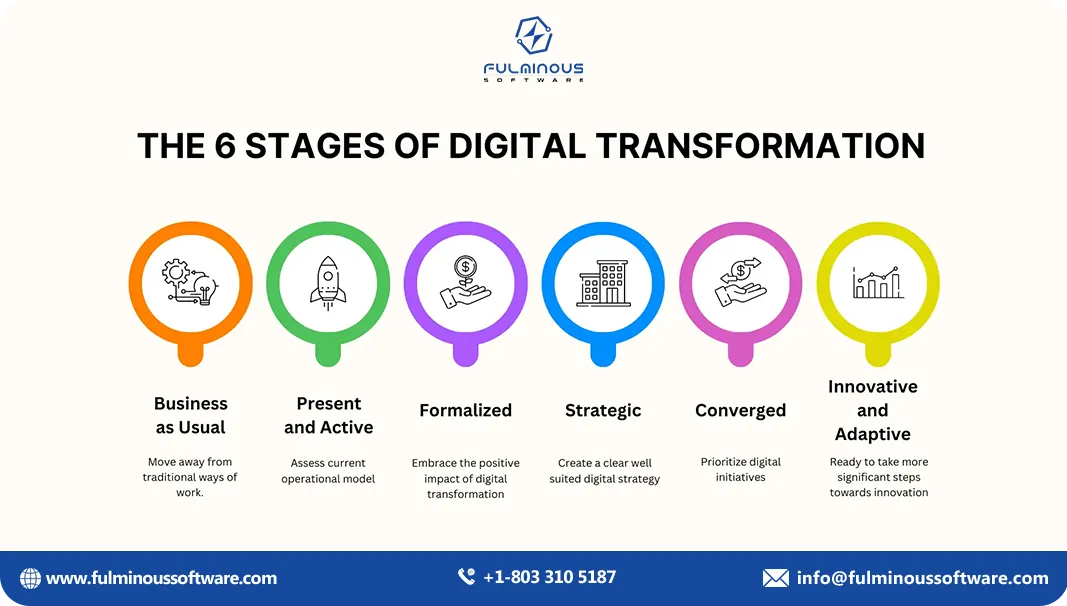

Trends in digital transformation are influencing every part of our lives—food, fashion, communication, and even the way people think. If you continue to rely on outdated methods, society may quickly label you as behind the times. Remember the old days when people used to work 24/7 and still struggled to meet production goals? Or when a single machine failure could halt production for days? Times have changed. Today, a manufacturing web design agency can help modern businesses adapt by integrating smart technologies, streamlining operations, and improving overall efficiency through digital solutions.

Now compare the current situation. Today, the manufacturing process has completely changed. Advanced technologies have changed the way factories work. At the same time, trends are supposed to change over time. Manufacturing businesses with futuristic visions are daily updating digitally. If you are a manufacturing business owner, you need to be aware of the current and upcoming trends. Here we are going to see it in detail.

Manufacturing Digital Transformation is an Ever-changing and Dynamic

Digital transformation in manufacturing is always changing, and if you don't keep up, you'll be left behind. Remember how fast smartphones, apps, and online shopping have changed? Well, the manufacturing industry is going through a similar thing. They're constantly trying out new tech to make things faster, cheaper, and better. It's like renovating and updating your home every year.

These changes aren't just about making things more efficient; they're changing the whole game. Some factories are becoming like smart homes, running almost on their own. It's like having a robot in your factory. If you want to stay competitive in manufacturing, you need to be on top of these changes. But if you can do it, you'll be rewarded big time.

Following the Trends in Digital Transformation: Top Secret of Successful Manufacturers

Do you know how industry leaders achieve sustainable success? The only answer is their willingness and eagerness to follow the trends in upgrading digitally. Absolutely! Following digital transformation trends is like having a secret weapon in your manufacturing business. It's the key to staying ahead of the competition and achieving long-term success. If you're not embracing digital technologies, you're missing out on opportunities to improve your efficiency, reduce costs, and enhance customer satisfaction.

Adapting to the Latest Trends: A Critical Step in Digital Transformation

The manufacturing world is constantly evolving, just like the apps on your phone. If you're stuck using an old app while everyone else is enjoying the latest features, you're going to miss out. The same goes for manufacturing. Being willing to change and adapt to the latest trends in digital transformation is like having an advantage in the world of manufacturing. Many time,s resistance to adapt and experiment is the major hindrance to achieving success.

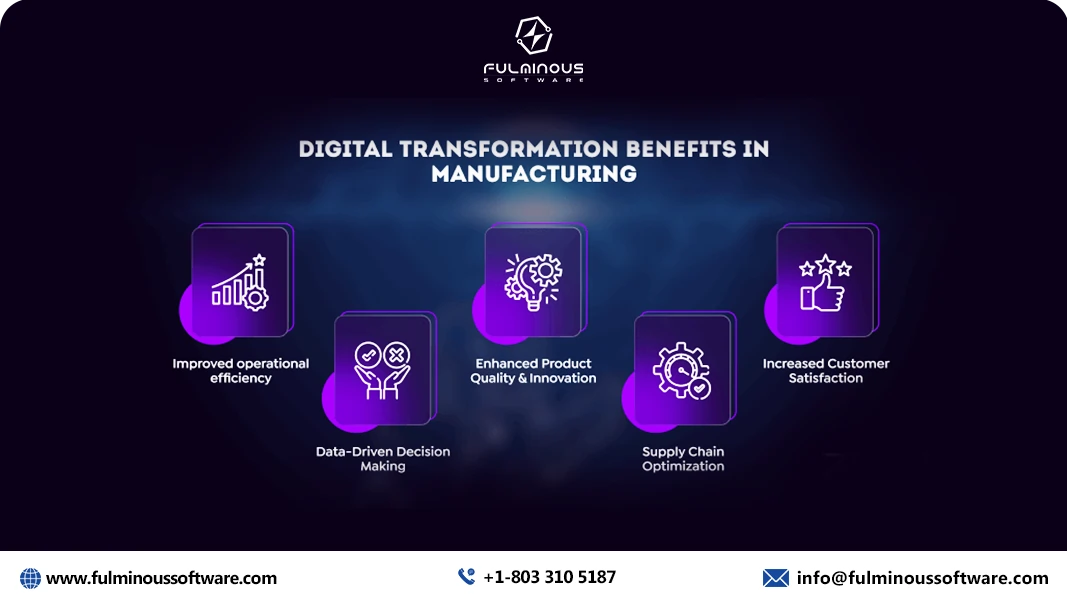

Why Following and Implementing Digital Transformation Trends is Essential for Manufacturing

Digital transformation is a necessity for the survival and growth of manufacturers. You may ask why following digital transformation trends is so important. Here's why:

1. Increased Efficiency and Productivity:

- Automation: Digital tools can automate repetitive tasks, freeing up human workers for more complex and strategic roles.

- Data-Driven Decision Making: By analyzing vast amounts of data, manufacturers can make informed decisions to optimize production processes and reduce waste.

2. Improved Quality and Consistency:

- Quality Control: Advanced technologies like machine learning can detect defects early in the production process, ensuring higher quality products.

- Standardization: Process standardization might result in more consistent results thanks to digital systems.

3. Enhanced Customer Experience:

- Customization: Digital technologies enable manufacturers to offer personalized products and services, meeting the specific needs of individual customers.

- Faster Delivery: Efficient digital supply chains can reduce lead times and get products to customers faster.

4. Cost Reduction:

- Energy Efficiency: Digital solutions can help optimize energy consumption, reducing operational costs.

- Inventory Management: Accurate inventory tracking can prevent stockouts and overstocking, saving money.

5. Competitive Advantage:

- Innovation: By embracing digital transformation, manufacturers can stay ahead of the competition by introducing innovative products and services.

- Agility: Businesses that use digital technologies can quickly adjust to shifting market conditions.

What if not following trends in Digital Transformation in Manufacturing

Let’s understand with a real-life incident. If you're running a bakery and you've been using the same old techniques for years, kneading dough by hand and baking bread in a brick oven. Can you compete with those who have advanced machines and technologies? But then, you discover a new bread machine that can do all the work for you and a high-tech oven that bakes bread perfectly every time.

Similarly, if you stick to your old ways, you'll probably be okay for a while. But as time goes on, you'll start to notice that others are making better products, faster, and at a lower cost. They're using modern equipment and techniques that you're missing out on.

In the world of manufacturing, if you don't embrace digital transformation, you risk falling behind your competitors. They'll be able to produce products more efficiently, at a higher quality, and at a lower cost.

So, what are the consequences of not following digital transformation trends?

- Decreased competitiveness: You'll struggle to compete with other manufacturers who are using modern technologies.

- Reduced profitability: Higher costs and lower efficiency can cut down your profits.

- Loss of market share: Customers will choose products from companies that are more innovative and efficient.

- Difficulty attracting and retaining talent: Top talent will want to work for companies that are at the forefront of technology.

In short, not following digital transformation trends can be a recipe for disaster.

Top 12 Trends in Digital Transformation for Manufacturing

Manufacturing is getting a major tech upgrade. From smart factories to artificial intelligence, new technologies are transforming the way products are made. Let’s see the top 12 Trends in Digital Transformation for Manufacturing.

1. Feature-rich Industrial IoT

Just like your phone tells you when the lights are on or the thermostat is set too high in a smart house, IIoT (Industrial Internet of Things) can tell you everything about your machines.

Consider it as your factory's personal assistant. IIoT connects all your machines and sensors, so they can talk to each other and share information. This means you can see exactly what's going on in real time, from how fast your machines are running to how much energy they're using.

With IIoT, you can:

- Predict problems before they happen: Just like your phone can predict when your battery is about to die, IIoT can predict when your machines might break down.

- Keep your machines running smoothly: By monitoring their performance, you can schedule maintenance and repairs at the best time, minimizing downtime.

- Reduce waste: IIoT can help you optimize your production process, so you're not wasting materials or energy.

- Make smarter decisions: With all the data IIoT gives you, you can make better choices about how to run your factory.

2. Software-driven Manufacturing

Software-driven manufacturing is a new trend in the manufacturing industry, allowing for greater flexibility. With the right software, you can streamline your operations, automate tasks, and improve collaboration between teams. It's like having a personal assistant that helps you manage everything from your supply chain to your quality control.

Software-driven manufacturing can help you become more flexible and adaptable, so you can respond quickly to changes in the market and develop new products faster. It's like having a turbocharger for your factory!

These are just a few of the main advantages of software-driven manufacturing:

- Increased efficiency: Software can automate repetitive tasks, freeing up your employees to focus on more strategic work.

- Improved quality: Software can help you identify and address quality issues before they become problems.

- Enhanced collaboration: Software can break down silos and improve communication between teams.

- Reduced costs: Software can help you optimize your operations and reduce waste.

- Faster time to market: Software can help you develop and launch new products more quickly.

3. Advanced Smart Factories

In a smart factory, everything is connected. Machines, robots, and even the walls are all talking to each other, sharing information, and working together to make things more efficient. It's like having a super-smart brain that runs your entire factory.

With smart factories, you can:

- Monitor everything in real-time: See exactly what's happening on the factory floor, from how fast your machines are running to how much energy they're using.

- Predict problems before they happen: Just like your phone can predict when your battery is about to die, smart factories can predict when machines might break down.

- Reduce waste: By optimizing your production process, you can minimize waste and save money.

- Make smarter decisions: With all the data you collect, you can make better choices about how to run your factory.

4. Manufacturing Rooted in the Value of Experience

Your staff are your most valuable asset, as this trend acknowledges. They have the skills, knowledge, and experience to make a huge difference in your business.

By investing in training and development, you can help your employees grow and learn new things. This will not only make them happier and more engaged, but it will also improve the quality of your products and services.

Plus, understanding your customers is key to success. By listening to their feedback and paying attention to their needs, you can develop products that they love. Your consumers will remain loyal to you, and you will be able to establish good relationships with them as a result.

So, if you want to create a thriving manufacturing business, it's time to focus on the value of experience. By investing in your employees and understanding your customers, you can achieve great things.

5. AI-Driven Production

Large data sets can be analyzed by AI, which can also spot patterns that humans would overlook. This can help you optimize your production process, reduce waste, and improve quality control.

For example, AI can predict when your machines are likely to break down, so you can schedule maintenance before they fail. This helps you avoid costly downtime and keep your factory running smoothly.

AI can also help you manage your supply chain better. By predicting demand fluctuations, you can ensure that you have the right amount of materials on hand, avoiding stockouts or excess inventory.

As AI technology continues to improve, manufacturers that embrace AI-driven solutions will be able to stay ahead of the competition and achieve greater productivity and cost savings. It's like having a secret weapon in your factory!

6. Complete Automation

Automation technologies, like robots and advanced machinery, can take over repetitive tasks, freeing up your employees to do more creative and strategic work. This can make your employees happier and more engaged because they'll be able to use their skills and talents to the fullest.

Plus, automation can help improve the quality and consistency of your products. Machines can perform tasks with precision and accuracy, reducing the risk of errors and ensuring that all your products are made to the same high standard.

So, if you want to make your factory more efficient, more productive, and more enjoyable for your employees, complete automation is the way to go!

7. Advancing the Sustainable Development Goals (SDGs)

By adopting sustainable practices, manufacturers can reduce their impact on the environment, create a better world for everyone, and even improve their brand reputation.

Here are some ways manufacturers can be more sustainable:

- Use less energy: By implementing energy-efficient technologies, manufacturers can reduce their carbon footprint and save money on energy bills.

- Reduce waste: Recycling materials and minimizing waste can help protect the environment and save resources.

- Promote ethical labor practices: Ensuring that workers are treated fairly and have safe working conditions is essential for a sustainable business.

8. Data-Driven Decisions

Imagine having a crystal ball that can predict the future of your factory. That's the power of data-driven decision-making!

By collecting and analyzing data from your machines, supply chain, and customers, you can get a clear picture of what's happening in your business. This can help you identify trends, spot problems early, and make better decisions.

It's like having a super-smart assistant that can help you navigate the challenges of running a manufacturing business. You may become more successful, flexible, and responsive by using data-driven decision-making.

The following are a few advantages of making decisions based on data:

- Improved efficiency: Finding obstacles and simplifying your production processes are both possible with data analysis.

- Enhanced quality control: Data can help you detect and prevent defects before they become problems.

- Reduced costs: Data-driven decisions can help you reduce waste and save money.

- Increased customer satisfaction: By understanding your customers' needs, you can develop products that meet their expectations.

9. Profitable Digital Twins

Digital twins are virtual replicas of your physical assets, like machines or processes. They can help you simulate and analyze your operations in real-time, giving you valuable insights into how things are working.

With digital twins, you can:

- Monitor your equipment's health: You can keep a check on the health of your machines, just like a doctor can keep an eye on yours.

- Optimize your production process: Find out what's working and what's not, and make changes to improve efficiency.

- Design better products: Test new designs and make improvements before you even build them.

Digital twins are like having a crystal ball for your factory. They can help you predict problems before they happen, reduce downtime, and improve the quality of your products. It's like having a super-powered tool that can help you achieve your goals.

10. Edge Computing

Edge computing is like a local superhero base that processes information quickly and locally. It's faster than sending everything back to a central headquarters, so your machines can respond to changes in real-time.

With edge computing, your factory can:

- Make decisions faster: If a machine starts to malfunction, edge computing can detect the problem and take action immediately, without waiting for information to be sent to a central server.

- Improve efficiency: By processing data locally, you can reduce the amount of data that needs to be transmitted, saving time and money.

- Enhance security: Edge computing can help protect your data by keeping it closer to your factory, reducing the risk of cyberattacks.

11. Cloud Integration

Cloud integration is like a super-powered communication network that connects all your machines and systems. It's like having a group chat app for your factory, where everyone can share information and collaborate in real-time.

With cloud integration, you can:

- Improve teamwork: Break down silos and get everyone working together more effectively.

- Make better decisions: Share data and insights across teams to make informed decisions.

- Save money: Cut costs by using cloud-based solutions instead of investing in expensive on-premises infrastructure.

12. Client-Centered Production with Technologies

This trend is all about understanding your customers and making products that are just right for them. It's like having a personal shopper for your customers, helping them find exactly what they need.

With technology, you can collect data and analyze it to understand your customers' preferences. This helps you tailor your products to their specific needs, making them feel special and valued.

You can also use technology to engage with your customers throughout the production process. You may produce goods that your customers would adore by doing this, which also fosters transparency and trust.

By focusing on client-centered production, you can differentiate yourself from your competitors and build strong relationships with your customers. It's like having a secret weapon in your manufacturing business!

Implement Digital Transformation in Manufacturing for Big Gains

There is no benefit to just holding this information. If you want to take advantage, you have to implement the trending digital transformation solutions that suit your manufacturing business. Implementing digital transformation in your manufacturing process can bring a ton of benefits. It’s all about using the latest tech to make your operations run smoother, faster, and smarter.

No doubt, this is the right time to act. Otherwise, you will be late. Because the leading manufacturing businesses are seeking and implementing the latest trends in digital transformation. You need to stay ahead of them to reach the top of the manufacturing sector.

Collaborating with Trend-Focused Tech Firms Boosts Manufacturing Digital Growth

If you want to be a big player in manufacturing, you need to team up with a tech company that knows its stuff. These guys are always on top of the latest trends and can help you use the coolest tools and strategies to stay ahead of the competition.

For example, Fulminous Software is a leading digital transformation service provider for manufacturers with deep knowledge of trends in manufacturing digital transformation. When you seek assistance from a digital transformation expert like us, you can get top-class solutions with the latest technologies and continuous support by upgrading your manufacturing factories with trending ones.

That's what partnering with a tech company is like. They'll help you navigate the crazy world of digital transformation and make sure you're always one step ahead.

Conclusion

In simple words, following trends in manufacturing digital transformation and its careful integration is a vital part of the current manufacturing business process. The above information gives us clear guidance that never ignore the importance of following the latest trends in the digital transformation of manufacturers.

Feature-rich Industrial IoT, Software-driven Manufacturing, Manufacturing Rooted in the Value of Experience, AI-Driven Production, Complete Automation, Advancing the Sustainable Development Goals (SDGs), Data-Driven Decisions, Profitable Digital Twins, Edge Computing, Cloud Integration, and Client-Centered Production with Technologies are the latest trends in the digital transformation of manufacturers.

As we learn from industry toppers, we must follow their key secret, which is following the latest trend and adapting it as soon as possible. Asking for assistance from a leading service provider of digital transformation is a perfect idea to have a smooth and tension-free digitalization process. If you want to know more or get assistance, you can contact our digital transformation experts now.

FAQs

- Q1: What is digital transformation in manufacturing?

- A: Digital transformation in manufacturing involves using advanced technologies to improve efficiency, quality, and customer experience while reducing costs and enhancing competitiveness.

- Q2: Why is following digital transformation trends essential for manufacturers?

- A: Following digital transformation trends helps manufacturers stay competitive by optimizing processes, reducing waste, enhancing product quality, and improving customer satisfaction.

- Q3: How can AI fit into the manufacturing process?

- A: AI helps manufacturers by optimizing production processes, predicting machine failures, managing supply chains, and improving overall product quality and efficiency.

- Q4: What are smart factories in manufacturing?

- A: Smart factories use interconnected machines, sensors, and software to monitor production in real-time, predict issues, reduce waste, and make data-driven decisions.

- Q5: How does automation benefit manufacturing?

- A: Automation improves efficiency by taking over repetitive tasks, allowing employees to focus on more strategic work, and ensuring consistent product quality.

- Q6: What is Industrial IoT (IIoT) in manufacturing?

- A: IIoT connects machines and sensors to collect data, predict failures, optimize performance, and streamline production processes, improving factory operations.

- Q7: What is software-driven manufacturing?

- A: Software-driven manufacturing uses digital tools to automate tasks, improve collaboration, streamline operations, and enhance production flexibility and efficiency.

- Q8: What is edge computing in manufacturing?

- A: Edge computing processes data locally at the factory level, enabling faster decision-making, improving efficiency, and enhancing data security.

- Q9: How can manufacturers benefit from digital twins?

- A: Digital twins provide virtual models of physical assets, allowing manufacturers to simulate, monitor, and optimize production processes in real-time.

- Q10: What are the risks of not following digital transformation trends in manufacturing?

- A: Not following trends can lead to reduced competitiveness, higher costs, lower efficiency, loss of market share, and difficulty attracting talent.

HIRE A TOP SOFTWARE DEVELOPMENT COMPANY

Verified

Expert in Software & Web App Engineering

Verified

Expert in Software & Web App Engineering

I am Manish Kumawat, co-founder of Fulminous Software, a top leading customized software design and development company with a global presence in the USA, Australia, UK, and Europe. Over the last 10+ years, I am designing and developing web applications, e-commerce online stores, and software solutions custom tailored according to business industries needs. Being an experienced entrepreneur and research professional my main vision is to enlighten business owners, and worldwide audiences to provide in-depth IT sector knowledge with latest IT trends to grow businesses online.

Partner with Top-Notch Web Application Development Company!

Discuss your Custom Application Requirements on info@fulminoussoftware.com or call us on +1-903 488 7170.

15 Days Risk-Free TrialRecommended Articles