Digitalization in Manufacturing: Changing Industry Practices

Manish Kumawat

Last Updated on: 07 October 2025

Hey there!

Do you remember those old factories with people doing everything by hand, having unexpected maintenance and regular expenditure? Well, those days are long gone. Now, it's all about computers, internet, mobile phones, robots, and smart machines.

Visualize a factory where machines collaborate with each other, learn from, and adapt to one another in addition to working nonstop. This is the vision of the digital factory, a concept that is rapidly transforming the manufacturing landscape. As the world is growing with advancements in technology, it's time to learn more about digitalization in the manufacturing sector.

In this blog, we'll explore the various topics related to how digitalization is changing the manufacturing industry.

The Manufacturing Process Evolution: From Manual to Digital

Back in the day, the manufacturing process was all about people doing things by hand or using big machines. But then computers came along and started changing things up. In the 21st century, we really got into using digital tools to make things faster and better.

Computers and technology are now used for everything, including designing, manufacturing, and even customer service. In order to make informed decisions, do more, and maintain our competitive edge, we have access to software, cloud services, intelligent devices, and vast amounts of data.

Let's See the Term ‘Digitalization’

Consider digitalization as an investment similar to buying a brand-new phone. It's about using technology to take something old and turn it into something new and improved. To be more productive, intelligent, and efficient in the manufacturing industry, it refers to the use of computers and software. Machines and computers thus take over from people, producing goods like automobiles, phones, and even food in a far more contemporary manner.

Benefits of Digitalization in Manufacturing

Investment without stable benefits must be avoided if you are looking for manufacturing success. Same in digitalization, we need to consider the benefits before investing in it.

Faster and Cheaper:

- Robots do the work: Machines can work 24/7 and make fewer mistakes.

- Data helps: Computers tell us what's working and what's not, so we can fix things quickly.

Better Products:

- Catch problems early: We can spot flaws before they become big issues.

- Make things just the way you want: We can customize products easily.

More Flexible:

- Change things fast: If something changes, we can adjust quickly.

- Handle different orders: We can make a variety of products without much trouble.

Good for the Environment:

- Save energy: We can use less electricity and waste less stuff.

- Reduce pollution: We can make things cleaner.

Smarter Decisions:

- Use data to guide choices: We can use information to make better choices.

- Predict the future: We can guess what will happen next and plan accordingly.

Digitalization in Manufacturing: More Than Just a Website

While having a manufacturing website design is undoubtedly an important aspect of a modern manufacturing business, it's just one piece of the digital puzzle. True digitalization goes far beyond a simple online presence.

Manufacturers have the misperception that all it takes to run a successful business is a website. But, it's about integrating digital technologies into every aspect of the manufacturing process, from design and production to supply chain management and customer service. This involves leveraging data analytics, automation, artificial intelligence, and the Internet of Things (IoT) to optimize operations, improve efficiency, and enhance product quality.

For example, IoT-enabled sensors can monitor equipment health in real-time, allowing for predictive maintenance and reducing downtime. Large volumes of data can be analyzed by AI-powered algorithms to spot trends and improve production procedures. Additionally, automation can improve productivity, decrease human error, and streamline procedures.

In essence, digitalization in manufacturing is about using technology to create a more connected, intelligent, and efficient business. It's about transforming the way products are designed, produced, and delivered to meet the evolving needs of customers in the digital age.

Digitalization is not a Choice

For manufacturing companies, digitalization is now a need, not an option. It's like attempting to manage a restaurant without a kitchen. You could certainly continue to serve meals, but it won't be very good, and your firm would most likely fail.

You can increase overall productivity, grow your competitiveness, and streamline your procedures with digital technologies. Using technology to alter your entire business is more important than just having a website. Therefore, this is the perfect moment to embrace digitalization if you've been hesitant to do so. Manufacturing will become computerized in the future.

Key Technologies Driving Digitalization

Digitalization in manufacturing is powered by a range of technologies that work together to optimize processes and deliver better outcomes.

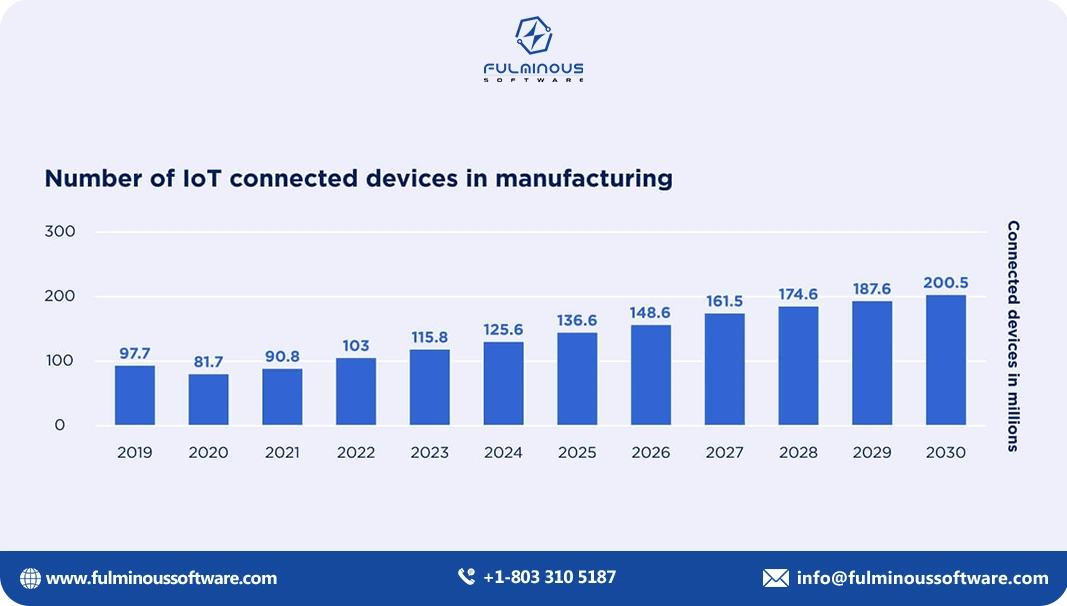

1. Internet of Things (IoT):

Think of IoT development as a network of connected devices that can talk to each other and share information. In a factory, this means machines, sensors, and even products can communicate in real time.

For example, a sensor on a machine might detect a problem and send a message to a central computer, which can then take action to fix it before it becomes a bigger issue. This helps prevent downtime and keeps things running smoothly. The size of the global IoT market for manufacturing is projected to grow at a compound annual growth rate (CAGR) of 10.7% from 2024 to 2034 to reach approximately USD 181.86 billion. (source)

Benefits:

- Real-time info: Things can talk to each other, helping you make better decisions.

- Predict problems: You can see when machines might break and fix them before they do.

- Save money: This helps you work faster and spend less.

2. Artificial Intelligence (AI) and Machine Learning (ML):

AI and ML are exactly the same as a digital factory's brains. They can analyze huge amounts of data from machines, sensors, and other sources to identify patterns and make predictions.

For instance, an AI system might be able to predict when a machine is likely to break down based on its performance data, allowing for preventative maintenance. This can save time and money by avoiding unexpected downtime. It is projected that the artificial intelligence industry in manufacturing will reach $16.3 billion by 2027. (source)

Benefits:

- Smart thinking: Computers can analyze lots of data and learn from it.

- Predict problems: You can see when machines might break and fix them before they do.

- Save time and money: This helps you work faster and spend less.

3. Robotics:

Robots have been a part of manufacturing for years, but they’re becoming even more advanced thanks to digital technology. Robots that collaborate with humans, often known as "cobots," are capable of doing hazardous or repetitive activities alongside humans.

Benefits:

- Do the boring stuff: Robots can do repetitive or dangerous tasks.

- Work together: Robots can work alongside people to get things done faster.

- Stay safe: This helps keep people safe in dangerous places.

4. 3D Printing:

With the use of technology, 3D printing makes it possible to turn digital drawings into tangible products. It’s being used in manufacturing to produce everything from prototypes to final products.

Benefits:

- Make things fast: You can make things quickly and easily.

- Save money: This can help you spend less.

- Make things exactly how you want: You can customize your products.

5. Cloud Computing:

Cloud computing is like having a powerful computer that you can access from anywhere. Manufacturers can use the cloud to store and analyze data, run software applications, and collaborate with partners. This can help reduce costs, improve flexibility, and enable remote work. By 2030, the cloud manufacturing market is expected to grow to a value of $200 billion. (source)

Benefits:

- Work from anywhere: You can access your data and programs from anywhere.

- Save money: You don't need expensive computers in your office.

- Work together: You can work with people all over the world.

6. Augmented and Virtual Reality (AR/VR):

AR and VR are technologies that can enhance the way we interact with the physical world. In manufacturing, AR can be used to provide workers with real-time information and instructions, while VR can be used for training and simulation.

Benefits:

- Learn better: You can learn new things in a fun and interactive way.

- Work faster: You can get live information and instructions.

- Stay safe: You can practice things in a safe virtual environment.

7. Big Data Analytics:

Examining massive databases for trends and patterns is known as big data analytics. In manufacturing, this can be used to optimize production processes, improve quality control, and reduce waste. The size of the big data analytics market in manufacturing is projected to be $9.07 billion in 2024 and grow to $19.55 billion by 2029. (source)

Benefits:

- Use data to improve: You can use data to manufacture things at their best.

- Find problems: You can find problems in your products before they become big issues.

- Save resources: You can use less stuff and waste less.

8. Cybersecurity:

As factories become more connected and reliant on digital technology, cybersecurity is becoming increasingly important. Protecting against cyber threats is essential to ensure the security and integrity of manufacturing operations.

Benefits:

- Protect your data: You can keep your data safe from hackers.

- Keep things running smoothly: You can make sure your factory keeps working without problems.

9. Digital Twin Technology:

A digital twin is a virtual replica of a physical asset, such as a machine or product. It allows manufacturers to simulate and test changes in production processes without disrupting the actual operation.

Digital twins improve product development, maintenance planning, and process optimization. A $48.2 billion USD market for digital twins is predicted by 2026, reflecting the growing use of digital twins in manufacturing. (source)

Benefits:

- Test things before you do them: You can try out changes in your factory without actually making them.

- Make things better: This can help you make your products and processes better.

- Prevent problems: You can see problems before they happen.

These are just a few of the many technologies that are driving the digital transformation of manufacturing.

How Digitalization Is Changing Industry Practices

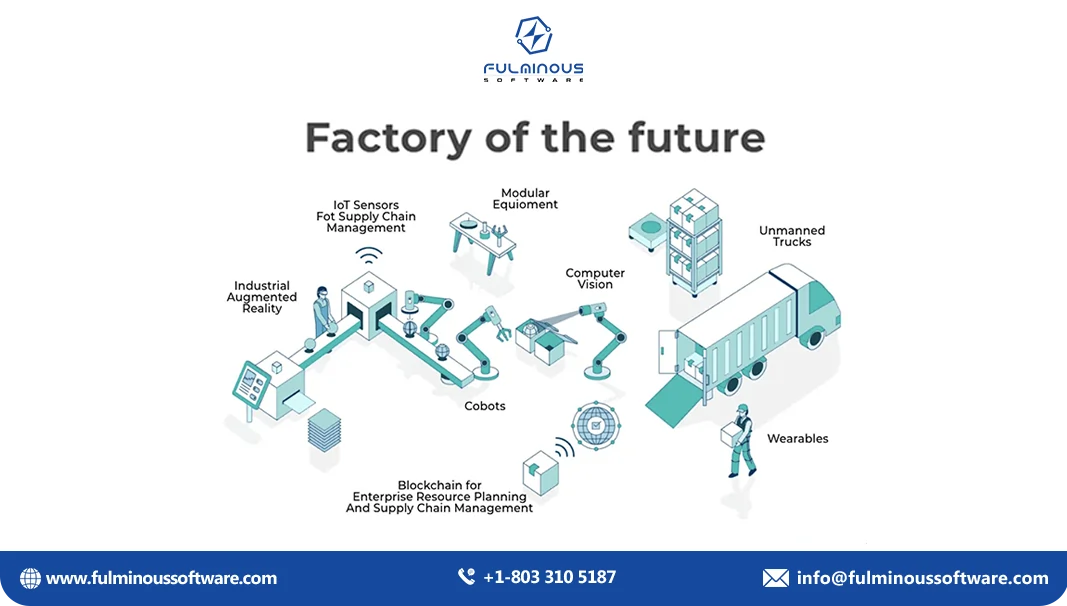

The integration of digital technologies is transforming several key areas of the manufacturing industry, leading to more efficient, flexible, and sustainable practices. Below are some of the ways digitalization is changing traditional manufacturing practices:

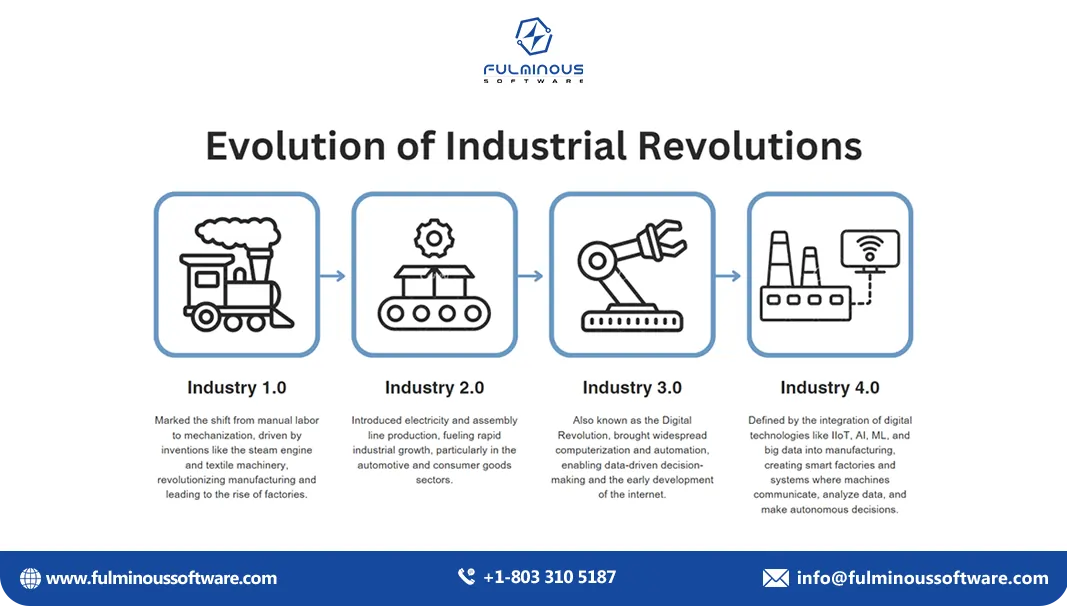

a. Smart Factories and Industry 4.0

The Fourth Industrial Revolution, or Industry 4.0, is a concept that represents the merging of digital and physical systems in manufacturing. Smart factories, a key component of Industry 4.0, are equipped with IoT devices, sensors, and AI-powered software that enable autonomous decision-making and process optimization. These factories can adjust to changes in demand, reduce energy consumption, and improve product quality.

b. Predictive Maintenance

One of the biggest advantages of digitalization is the ability to predict when machinery is likely to fail, allowing manufacturers to perform maintenance before a breakdown occurs. By using IoT sensors and AI-driven analytics, companies can monitor equipment health in real-time, reducing unplanned downtime and extending the lifespan of machinery.

c. Supply Chain Optimization

Digitalization is streamlining supply chain management by providing greater visibility into inventory levels, production schedules, and shipping logistics. With the help of AI and big data analytics, manufacturers can anticipate demand fluctuations, avoid stockouts, and reduce lead times. Additionally, blockchain technology is being used to enhance transparency and traceability across supply chains.

d. Customization and Flexibility

Consumer demand for personalized products is pushing manufacturers to adopt more flexible production methods. Digitalization enables companies to create customizable products at scale by leveraging 3D printing, automation, and data-driven design tools. This shift toward mass customization allows manufacturers to meet individual customer preferences without sacrificing efficiency.

e. Enhanced Quality Control

Quality control has traditionally relied on manual inspections and sampling, but digital technologies are changing this practice. AI-powered vision systems, sensors, and machine learning algorithms can detect defects in real time, ensuring that only high-quality products are delivered to customers. Digitalization also enables manufacturers to trace the source of defects and implement corrective actions quickly.

Overcoming Challenges in Digitalization

| Challenge | Solution | Technology |

|---|---|---|

| Cost | Automation, innovation, partnerships | Robotics, AI, IoT |

| Competition | Innovation, differentiation, branding | Product design, marketing, data analytics |

| Technology | Research and development, training, partnerships | Cloud computing, AI, machine learning |

| Labor | Training, automation, flexible work arrangements | Robotics, AI, virtual reality |

| Sustainability | Eco-friendly materials, waste reduction, energy efficiency | IoT, renewable energy, sustainable materials |

The Top Secret to Digital Success: Partner with Tech Giants

Want to make your business a digital powerhouse? The secret might be simpler than you think: team up with a tech giant. These tech companies have the brains, brawn, and resources to help you level up.

Can you dream of having access to their cutting-edge technology, from AI that can predict customer needs to cloud computing that makes your data super fast? Plus, they have a team of experts who can guide you through the digital maze.

By partnering with a leading technology service provider like Fulminous Software, you're not just getting their tools; you're also tapping into their network and reputation. This can open doors to new opportunities and give your business a major credibility boost. So, if you're serious about digital transformation, consider teaming up with a tech titan. It could be the move that takes your business to the next level.

By working with them, you can:

- Get access to the best tech

- Learn from the experts

- Boost your credibility

- Expand your reach

The Future of Digitalization in Manufacturing

Digital tech is getting even cooler! New techs like 5G, supercomputers, and quantum computers will make factories even more amazing. Robots and AI will work together to make things automatically, and they'll get better at it over time. It's like having a super-smart team that never gets tired or makes mistakes.

Companies that use this new tech will have a big advantage. They'll be able to make things faster, cheaper, and more personalized. It's like having a superpower in the manufacturing world!

So, if you're in manufacturing, get ready for a digital revolution!

Case Study: Digitalization in Apple

Challenges Before Digitalization

Before embracing digitalization, Apple faced several challenges common to large-scale manufacturing:

- Supply Chain Complexity: Managing a global supply chain with multiple suppliers posed a challenge in terms of efficiency, traceability, and responsiveness.

- Product Customization: Rapidly evolving consumer demands require higher flexibility in production processes, making it difficult to keep up with the desired levels of customization.

- Sustainability: Apple faced growing pressure to reduce its environmental impact, necessitating the need for more sustainable manufacturing practices.

- Cost Efficiency: Increasing labor and material costs made it necessary to explore ways to enhance efficiency while maintaining high product quality.

Digital Transformation Strategy

Apple embarked on a digitalization journey by integrating several advanced technologies into its manufacturing ecosystem. The company adopted the following technologies to drive efficiency and improve its manufacturing practices:

Internet of Things (IoT)

Apple integrated IoT devices into its production lines to monitor equipment performance, track product components, and improve efficiency. IoT sensors allowed Apple to collect real-time data from machines and production lines, facilitating predictive maintenance, reducing downtime, and ensuring smooth operations.

Benefit: Reduced equipment downtime by 20% and increased production efficiency by 15%.

Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML were deployed to optimize Apple's manufacturing processes by analyzing vast amounts of data. AI algorithms detected patterns, predicted equipment failures, and optimized workflows in real-time. This automation allowed Apple to streamline production and reduce human error.

Benefit: Improved defect detection rates by 30% and reduced waste through more efficient resource management.

Robotics and Automation

Apple integrated advanced robotics into its assembly lines to handle repetitive tasks with precision and speed. Collaborative robots (cobots) worked alongside human workers, allowing for increased flexibility in production. Automation helped Apple increase its production capacity while maintaining product quality.

Benefit: Enhanced productivity by 25%, leading to faster product assembly and delivery.

3D Printing

Apple used 3D printing technology to rapidly prototype and customize product components. This innovation helped the company create complex designs, reduce lead times, and experiment with new materials, ultimately speeding up the product development cycle.

Benefit: Reduced prototyping time by 50%, accelerating time-to-market for new products.

Sustainability through Digitalization

Apple integrated digital solutions to reduce its carbon footprint and waste. The company used AI-driven data analytics to optimize energy consumption in its factories and adopted IoT for better waste management. Furthermore, it embraced automation to ensure minimal material waste during production.

Benefit: Achieved a 70% reduction in carbon emissions across its production facilities and reduced material waste by 40%.

Key Results of Digitalization

- Increased Efficiency: Apple’s manufacturing plants became significantly more efficient due to the integration of digital tools. Real-time data monitoring and predictive analytics allowed for optimized production lines and reduced downtime.

- Enhanced Product Quality: AI and machine learning helped Apple catch defects early in the production process, leading to improved product quality and reduced returns.

- Greater Flexibility: By leveraging robotics and automation, Apple was able to quickly adapt its production lines to changes in demand and product customization, reducing lead times.

- Sustainability Goals Achieved: Through digitalization, Apple was able to achieve its ambitious sustainability goals, reducing waste and lowering energy consumption.

Lessons Learned

Apple’s digital transformation highlights several key lessons for manufacturers:

- Invest in Technology: Embracing advanced technologies such as IoT, AI, and robotics can drive efficiencies and improve product quality.

- Predictive Maintenance is Key: Monitoring equipment and predicting failures before they occur can reduce downtime and save significant costs.

- Sustainability Matters: Digitalization not only improves efficiency but also helps achieve sustainability goals, which are increasingly important in today’s manufacturing landscape.

- Collaboration Between Humans and Machines: The use of cobots shows how humans and robots can work together to optimize production and improve safety.

Apple’s digitalization journey illustrates how the integration of advanced technologies can transform manufacturing practices.

Do Not Delay Digitalization

Delaying digitalization can be a costly mistake for manufacturing businesses. Think of it like not upgrading your phone for years. Sure, it still works, but you're missing out on all the cool new features that can make your life easier.

The same goes for manufacturing. Digital tools can help you save money, improve quality, and stay ahead of the competition. So, don't let fear or uncertainty hold you back. It's time to embrace the digital future!

Conclusion

Are You Ready to Digitalize Your Manufacturing Business?

Digitalization is not just a trend; it is a fundamental shift in the way manufacturing companies operate. The integration of IoT, AI, big data analytics, and other digital tools is reshaping industry practices, leading to faster, more efficient, flexible, and sustainable manufacturing processes.

The digital factory isn't just a dream; it's becoming a reality.

But here's the catch: Those who don't embrace digitalization risk being left behind. It's like trying to compete in a marathon with a bicycle.

So, what are you waiting for? Dive into the digital world and unlock the full potential of your manufacturing business. It's time to step up your game and join the digital revolution.

FAQs

- Q1. What is digitalization in manufacturing?

- A: Digitalization in manufacturing involves using digital tools and technologies like AI, IoT, and robotics to optimize processes, improve efficiency, and reduce costs.

- Q2. How does IoT benefit manufacturing?

- A: IoT enables real-time monitoring, predictive maintenance, and better decision-making by connecting machines, sensors, and systems, improving productivity and reducing downtime.

- Q3. What is a smart factory?

- A: A smart factory integrates digital technologies like IoT, AI, and robotics to automate processes, improve efficiency, and make autonomous decisions in real-time.

- Q4. How does AI improve manufacturing processes?

- A: AI analyzes large data sets to optimize operations, predict equipment failure, and enhance quality control, helping manufacturers reduce costs and boost productivity.

- Q5. What is predictive maintenance in manufacturing?

- A: Predictive maintenance uses sensors and AI to monitor machinery performance, predicting failures before they occur, minimizing downtime, and extending equipment lifespan.

- Q6. How do robots enhance manufacturing efficiency?

- A: Robots perform repetitive, dangerous tasks with precision, improving productivity, safety, and allowing human workers to focus on more complex operations.

- Q7. How does 3D printing benefit manufacturing?

- A: 3D printing enables rapid prototyping, customization, and faster production of complex parts, reducing lead times, waste, and production costs.

- Q8. Why is cybersecurity important in digital manufacturing?

- A: Cybersecurity protects manufacturing data, systems, and operations from cyber threats, ensuring business continuity and preventing costly disruptions.

- Q9. How can big data analytics improve manufacturing?

- A: Big data analytics identifies trends and inefficiencies in production, helping manufacturers optimize processes, enhance quality control, and reduce waste.

- Q10. What is the role of cloud computing in manufacturing?

- A: Cloud computing offers manufacturers scalable data storage, access to applications from anywhere, and collaboration with global partners without needing expensive infrastructure.

HIRE A TOP SOFTWARE DEVELOPMENT COMPANY

Verified

Expert in Software & Web App Engineering

Verified

Expert in Software & Web App Engineering

I am Manish Kumawat, co-founder of Fulminous Software, a top leading customized software design and development company with a global presence in the USA, Australia, UK, and Europe. Over the last 10+ years, I am designing and developing web applications, e-commerce online stores, and software solutions custom tailored according to business industries needs. Being an experienced entrepreneur and research professional my main vision is to enlighten business owners, and worldwide audiences to provide in-depth IT sector knowledge with latest IT trends to grow businesses online.

Partner with Top-Notch Web Application Development Company!

Discuss your Custom Application Requirements on info@fulminoussoftware.com or call us on +1-903 488 7170.

15 Days Risk-Free TrialRecommended Articles