How to Reduce Equipment Downtime in Factories

Manish Kumawat

Last Updated on: 07 October 2025

Equipment downtime is one of the most frustrating moments and a nightmare for any manufacturer. Every minute of equipment downtime is equal to loss of time, revenue, energy, and effort. Definitely, no one looks forward to experiencing this.

Do you know?

According to Forbes, when the manufacturing line pauses, the typical automotive manufacturers lose $22,000 every minute. The annual cost of unexpected downtime to industrial businesses can reach $50 billion.

Any unscheduled downtime may result in serious adverse effects later on, such as:

- Decreased profits or a decline in revenue

- Reduced productivity

- Extended lead times

- Irate consumers or clients

- A higher frequency of accidents at work during startup and closure

If you are a manufacturing, engineering, or industrial business owner you might have gone through the same feeling. Don't think that you are alone, it is common in the manufacturing industry.

But, don't worry!

Here we discuss the most suitable solution available for this major challenge faced by manufacturing businesses. Yes, it is none other than the Internet of Things (IoT). What a satisfying experience if you could predict a machine meltdown before it happened. That's the magic of the Internet of Things (IoT) in manufacturing. Machines' sensors converse with computers, interact with robots in a smooth way, and you can keep an eye on everything from your phone. These sensors constantly gather data on things like temperature, vibration, and energy use.

After analyzing all of this data, the computer searches for trends and red flags. With IoT, you can maintain a competitive edge by keeping your manufacturing and equipment operating efficiently. Let’s explore tips and tricks to keep your equipment operating smoothly and efficiently.

What exactly is Equipment Downtime?

Imagine: the giant machine in your factory suddenly stops working! That is known as equipment downtime, and it causes various issues for manufacturers. Manufacturing businesses may lose hundreds, maybe millions, of dollars due to downtime. Reducing downtime helps you keep your production line running smoothly and efficiently, whether it is unplanned (due to unexpected breakdowns) or planned (during regular maintenance).

10 Common Causes of Equipment Downtime in Factories

The reason is plenty of downtime. Let's see the reasons behind these machine downtime:

- Surprise Breakdowns: Even the most dependable machines occasionally decide to shut off. Maybe there is an exhausted component, a power surge, or it's just bad luck. The worst thing that can happen to a manufacturer is an unexpected breakdown.

- Lack of Regular Maintenance Mishap: Think of your machines like high-performance athletes. They will eventually become inefficient and slow if they are not maintained on a regular basis. Ignoring or postponing routine maintenance inspections can result in unplanned downtime and possibly more serious issues later on.

- The Communication Issues: By the time it reaches the maintenance crew, things can get mixed up. Poor communication between operators, technicians, and management can lead to missed issues, improper fixes, and ultimately, more downtime.

- Poor Inventory Management: Imagine the following scenario: your production line is running smoothly when all of a sudden it stops. Why? You've run out of the essential components needed to keep things moving. Inventory mismanagement, unreliable suppliers, or unexpected delays in receiving materials can all lead to frustrating downtime.

- Human Errors: Even the most skilled operators can make mistakes. Maybe it's a programming error, an incorrect setting, or a simple case of accidentally hitting the wrong button. These human errors, while hopefully rare, can still contribute to equipment downtime and production delays.

- Power Problem: Factories are like hungry beasts that need a constant flow of electricity to keep things running. Power outages, voltage fluctuations, or even brownouts (reduced voltage) can all cause machinery to malfunction and production to come to an unwanted halt.

- Climate Chaos: Believe it or not, even nature can play a role in downtime. Extreme temperatures, humidity, or dust can all affect the performance of sensitive equipment, leading to operational hiccups and the need for adjustments (or even shutdowns) to maintain safety and quality.

- Cybersecurity Scare: In today's digital world, even factories are vulnerable to cyberattacks. Malicious software or hackers targeting control systems can cause major disruptions, leading to downtime and potentially causing safety hazards.

- Training Troubleshoot: Operating complex machinery requires specialized knowledge. Inexperienced or inadequately trained operators can make mistakes that lead to equipment damage or breakdowns.

- Data Disconnect Dilemma: Factories are generating a ton of data these days. But without proper analysis and understanding of this data, you might miss early warning signs of potential problems. This can lead to reactive maintenance instead of proactive measures that prevent downtime altogether.

Just a few of the frequent reasons responsible for equipment failures are listed above. You may prevent problems, lessen their effects, and maintain a productive factory by being aware of these reasons.

Cost of Downtime

The cost of downtime might vary based on your company's size, kind of operation, and length of downtime. See the stats:

- In a survey conducted by Statista with participants from all around the world, 25% said that the average hourly cost of their servers' unavailability was between $301,000 and $400,000.

- A medium-sized organization might lose hundreds of thousands of dollars for each hour of downtime, as measured by an average cost of downtime of almost $9,000 per minute, according to a study conducted by the Ponemon Institute.

- According to a recent IDC survey of the Fortune 1000, the average annual cost of unplanned application downtime ranges from $1.25 billion to $2.5 billion, while the average cost of an infrastructure failure is $100,000 per hour.

- An article from Big Panda discusses a study conducted by EMA research that reveals a concerning trend: although the average cost per minute increased by 60% for businesses with fewer than 10,000 employees, it decreased by 5% for the largest businesses.

- Siemens found that the expenses associated with unscheduled downtime are rising. An hour of unscheduled downtime now costs the manufacturer at least 50% more than it did two years ago in every industry evaluated. The report goes on to estimate that Fortune Global 500 industrial companies lose about $1.5 trillion a year due to unplanned downtime. This represents 11% of the turnover of these enterprises and is an increase of 65% in just two years.

How IoT Helps You Reduce Equipment Downtime in Manufacturing

What is IoT?

The Internet of Things (IoT) in manufacturing refers to a network that uses built-in sensors to link different kinds of machinery, equipment, and gadgets to the Internet. These sensors improve communication and facilitate the gathering and exchange of data, which has several advantages for the manufacturing process.

Applications of IoT in Manufacturing

What if your machines could talk to you, whispering secrets about their health and performance? That's the miracle of the Internet of Things (IoT) in action! The application of IoT is plenty. Let's see some amazing applications of IoT!

| Application | Benefits | Example |

|---|---|---|

| Predictive Maintenance | Monitor machine conditions like temperature, vibration, and pressure in real time. Predict potential equipment failures, allowing for maintenance to be scheduled before breakdowns occur, reducing unplanned downtime by up to 50%. | A car manufacturer implements IoT sensors on its assembly line machines to track their condition continuously. The sensors detect early signs of wear and tear, such as unusual vibrations or temperature fluctuations, predicting potential failures. |

| Real-Time Monitoring and Control | Real-time remote monitoring of equipment, providing instant alerts and diagnostics. Quickly addressing issues, thus minimizing downtime (TeamSense) (IIoT World). | A food processing plant uses IoT devices to monitor the operational status of its equipment in real time. When an anomaly is detected, such as a conveyor belt malfunction, an alert is sent to the maintenance team, allowing for immediate intervention. |

| Inventory Management | Track inventory levels in real-time, with automated tracking. Automate the reordering process to prevent stockouts or overstocking. Enhance supply chain visibility and coordination. | A pharmaceutical company employs IoT sensors to track raw material levels and finished products in its warehouse. The system automates the reordering process when inventory drops below a certain threshold, preventing stockouts or overstocking. |

| Quality Control | Monitor product quality during manufacturing. Detect defects early and take action promptly, saving millions of dollars each year. Gain deeper insights with quality data to improve and enhance product standards. | An electronics manufacturer integrates IoT sensors on its production line to inspect the quality of circuit boards. The sensors detect defects such as incorrect soldering or component misplacement early in the production process. Prompt corrective actions save millions of dollars each year by avoiding the cost of reworking or scrapping defective products. |

| Energy Management | Monitor energy consumption. Identify waste and reduce energy costs and environmental impact. Significantly reduce cost and improve overall operational efficiency. | A steel manufacturing plant utilizes IoT devices to monitor energy usage across different sections of the facility. The data collected helps identify areas of excessive energy consumption and wastage. |

| Safety and Compliance | Improve workplace safety by monitoring environmental conditions. Provide alerts for hazardous situations. Ensure compliance with industry regulations and standards, reducing the risk of non-compliance. | A chemical manufacturing company installs IoT sensors to monitor air quality and detect the presence of hazardous gases. If the sensors detect dangerous levels of toxic substances, alerts are sent to employees and safety personnel. |

Benefits of IoT in Manufacturing

- Reduce Unplanned Downtime: Reduce unnecessary downtime and ensure more consistent production processes by proactively addressing concerns using predictive maintenance and real-time monitoring.

- Increase Productivity and Reduce Costs: Minimize unexpected breakdowns, leading to increased productivity and lower operational costs. IoT helps maintain optimal production efficiency by preventing disruptions.

- Predictive Maintenance Impact: According to McKinsey, predictive maintenance can reduce machine downtime by 30 to 50 percent and increase machine life by 20 to 40 percent, enhancing overall equipment reliability.

- Boost Efficiency: Real-time monitoring and data analysis will be useful to optimize manufacturing operations, streamline workflows, and enhance decision-making.

- Reduce Energy Consumption: Implement preventative maintenance to identify and fix issues that cause excess energy use, leading to lower energy consumption and reduced utility costs in manufacturing processes.

- Improve Inventory Management: Leverage IoT to monitor inventory levels in real-time, automate reordering processes, and optimize stock levels, ensuring timely availability of materials and components.

- Enhance Quality: Implement continuous quality monitoring to detect and address defects early, ensuring that products meet high-quality standards and reduce waste due to faulty products.

- Meet High Product Standards: Maintain consistent product quality by using IoT-enabled quality control processes, ensuring products meet industry standards and customer expectations consistently.

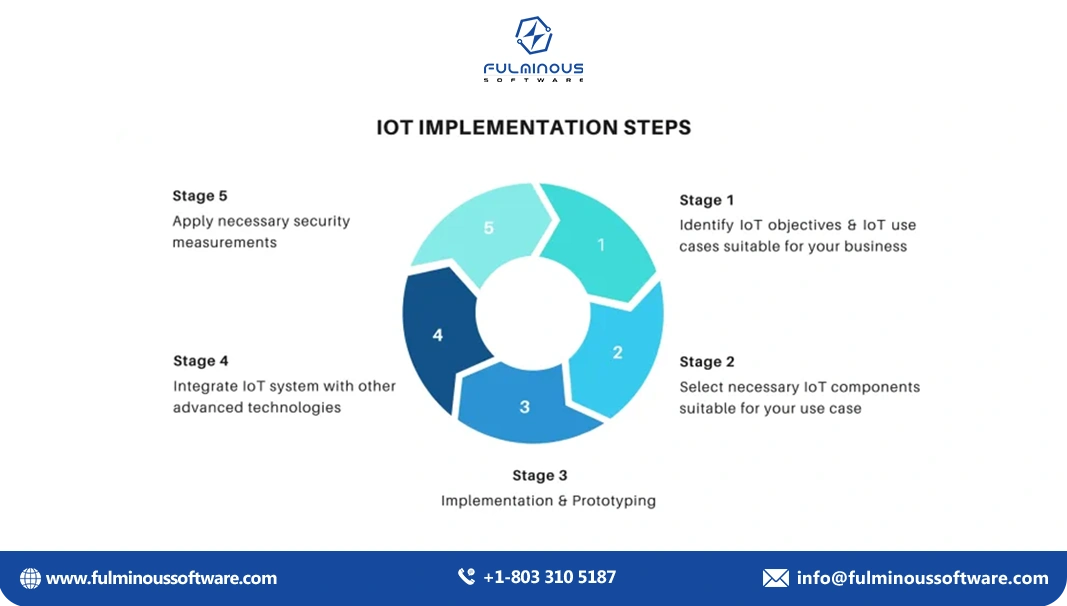

Implementing IoT Solutions in Your Factory

Step 1: Assess Your Needs

First, you gotta understand what needs fixing! Here's what to consider:

- Weak Points: What are the biggest challenges you face? Is it frequent equipment breakdowns? Inefficient production lines? Targeting these issues will help you decide which areas IoT can benefit the most.

- Current Infrastructure: What kind of technology do you already have? Are your machines compatible with sensors? Selecting the appropriate IoT solutions will be made easier if you know what you're working with.

- Data Goals: What kind of information do you want to collect? Is it real-time machine performance data? Inventory levels? Having clear goals helps you determine the type of sensors and data platforms you'll need.

Step 2: Research and Choose Your Sensors & Platforms

Now, it's time to choose your IoT sensors and platforms! Here are some tips:

- Sensors: Consider factors like the type of data you need, the environment your machines operate in, and compatibility with existing equipment. Energy meters, vibration sensors, and temperature sensors are examples of common sensors.

- Platforms: This is your data command center! Seek for feature-rich systems with data analytics tools, data visualization, and software integration.

Step 3: Test with Pilot Project!

Before you go ahead, it's wise to test with a pilot project. Choose a specific area (like a single machine or production line) and implement your chosen IoT solution. This helps you:

- Identify any compatibility issues between your existing systems and the IoT setup.

- Refine your data analysis processes to ensure you're extracting the most valuable insights.

- Train your team on using the new system and interpreting the data.

Step 4: Data, Glorious Data!

Once your pilot project is up and running, the real game begins – analyzing the data! Look for patterns, trends, and early warning signs.

- Predictive Maintenance: Is a machine showing signs of wear and tear? Use this data to schedule maintenance before it breaks down.

- Process Optimization: Can you identify areas where production slows down? By analyzing data flow and machine performance, you can optimize production lines for efficiency.

- Inventory Management: Are you constantly running out of materials? IoT is useful for tracking inventory levels in real time.

Step 5: Scaling Up – Your Factory's IoT Revolution!

Based on the success of your pilot project, it's time to expand! Implement IoT solutions across your entire factory, integrating them seamlessly with your existing systems. Don't miss to train your team on the new processes and how to use the data effectively.

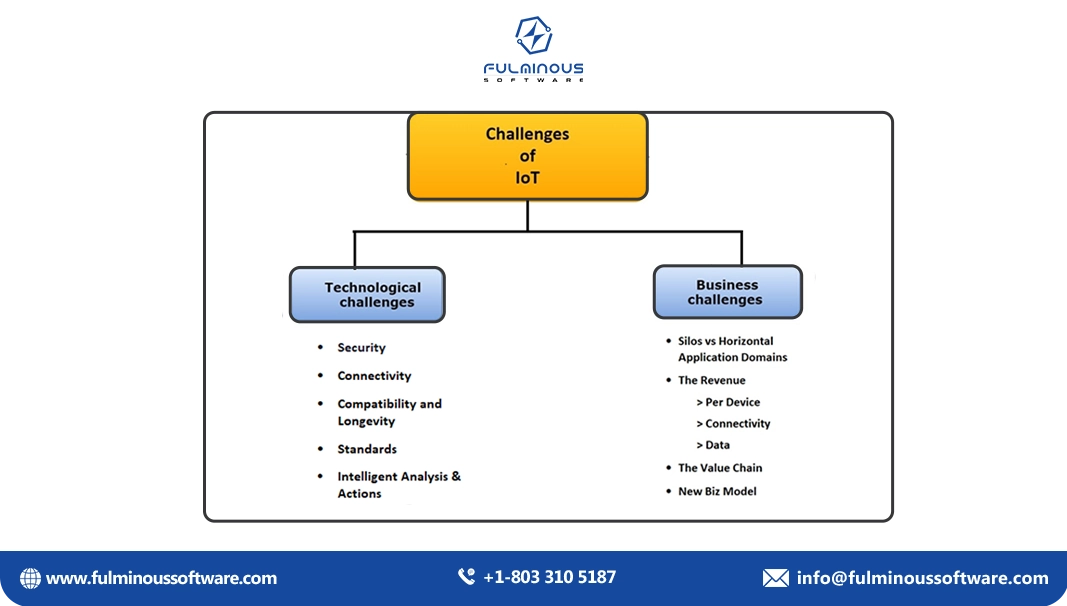

Upgrading Your Factory with IoT: Challenges and How to Conquer Them

Security Concerns: Keeping the Data Safe

Think of your factory's data as a treasure of valuable data. With IoT, this treasure gets connected to the internet, which can be risky! Here's how to keep the data safe:

- Security: Choose platforms with robust security features like encryption and multi-factor authentication. Think of it as a double-layered vault for your data.

- Regular Updates: Just like patching a leaky roof, regularly update your systems and software to stay ahead of potential cyber threats. It's like constantly reinforcing your data castle's defenses.

Integration Headaches: Bridging the Gap Between Old and New

Picture this: you get a fancy new gadget, but it doesn't work with your old equipment. That's the frustration of integration! Here's how to avoid the headache:

- Compatibility Check: Before buying, ensure your chosen sensors and platforms work seamlessly with each other and your existing factory systems. It's like buying the right adapter to plug your new tech into your old setup.

- IT Professionals: Don't hesitate to enlist the help of experienced IT professionals. They can be your knights in shining armor, helping navigate the integration process and ensuring a smooth transition.

Data Overload: Drowning in a Sea of Information

Imagine getting buried under a mountain of paperwork. That's what data overload can feel like! Here's how to stay afloat in the data sea:

- User-Friendly Platforms: Choose platforms with clear and easy-to-understand data visualization tools. Think of them as life jackets that help you see the valuable information amidst the data waves.

- Focus on What Matters: Don't try to analyze everything. Identify key metrics that directly impact your operations and prioritize those. It's like picking the most important documents from the paperwork pile.

Remember, with a little planning and the right tools, you can transform your operation into a data-driven powerhouse, leaving behind the days of frustrating guesswork and hello to a future of optimized production and efficiency!

Choosing the Right Tools for Your Factory Adventure

Selecting the right tools for your IoT journey is crucial for success. Here are some valuable tips to guide your way:

- Compatibility is King: Revisit this point because it's that important! Ensure everything works together like a well-oiled machine (see, we can use that phrase here!).

- Cost vs. Value: IoT solutions come in various price ranges. Weigh the cost against the value it will bring to your factory. Consider the long-term advantages and approach it as an investment in a high-tech update.

- Scalability for the Future: Don't get locked into a system that won't grow with your factory. Choose solutions that can be easily scaled up as your needs expand.

Real-World Examples of IoT in Manufacturing: Reducing Downtime

Case Study 1: Siemens’ Digital Factory

Siemens, a global leader in industrial manufacturing, has significantly reduced downtime in its digital factory in Amberg, Germany, using IoT technologies. The Amberg plant produces programmable logic controllers (PLCs) and is a benchmark for Industry 4.0 implementations.

Implementation and Outcomes:

Siemens implemented IoT sensors across the production line to monitor machine conditions such as temperature, vibration, and pressure in real time. The data collected is analyzed using advanced analytics and machine learning algorithms to predict equipment failures before they occur. As a result, the factory has achieved an availability rate of 99%, with unplanned downtime reduced by 20%.

Expert Insight:

Klaus Helmrich, a member of Siemens’ Managing Board, stated, “By leveraging IoT and digital twin technology, we have transformed our Amberg factory into a smart manufacturing hub. The real-time data analysis allows us to anticipate issues and perform maintenance before a breakdown, significantly reducing downtime and improving overall productivity.”

The Amberg manufacturing manager, Hans-Jürgen Brunner, continued, "Our maintenance procedures have been completely transformed by the incorporation of IoT. Because we can now anticipate when a machine may break and take preventative action, we have decreased downtime and increased the equipment's lifespan.”

Case Study 2: Harley-Davidson’s York Plant

Harley-Davidson, the iconic motorcycle manufacturer, implemented IoT solutions in its York, Pennsylvania, plant to enhance production efficiency and reduce downtime.

Implementation and Outcomes:

The company deployed IoT sensors to monitor the health and performance of its manufacturing equipment. These sensors give data that is fed into a centralized platform where powerful algorithms forecast possible problems and offer insights into the status of the equipment. By using predictive maintenance, equipment downtime has been decreased by over 25%, and overall equipment effectiveness (OEE) has been enhanced by 10%.

Expert Insight:

Monica McCabe, Director of Operations at Harley-Davidson, noted, “IoT has enabled us to transition from reactive to predictive maintenance. By analyzing data from our machinery, we can foresee potential issues and address them before they lead to downtime. This shift has had a profound impact on our production efficiency and product quality.”

John King, the plant manager at York, shared, “The implementation of IoT has been a game-changer for us. We’ve seen a significant reduction in unplanned downtime, which has allowed us to meet production targets more consistently. The insights we gain from real-time data have also helped us improve our maintenance strategies.”

Case Study 3: Bosch’s Automotive Electronics Plant

Bosch, a leading supplier of technology and services, has implemented IoT solutions in its automotive electronics plant in Juarez, Mexico, to enhance operational efficiency and reduce downtime.

Implementation and Outcomes:

Bosch equipped its manufacturing lines with IoT sensors to monitor various parameters such as temperature, humidity, and machine vibrations. The gathered data is examined to forecast equipment malfunctions and plan maintenance tasks in advance. With this strategy, unscheduled downtime has decreased by 15% and productivity has increased by 12%.

Expert Insight:

The chairman of Bosch Mobility Solutions, Dr. Stefan Hartung, said, "We can now optimize our manufacturing processes using IoT technologies. We can guarantee that our equipment runs as efficiently as possible by utilizing predictive maintenance, which will reduce downtime and increase production.”

The Juarez plant manager, Carlos Ramirez, made the following observation: "The implementation of IoT has greatly enhanced our maintenance operations. Our ability to recognize possible problems before they become serious ones has significantly decreased our downtime and increased the effectiveness of our output.”

Case Study 4: GE Aviation’s Engine Manufacturing Plant

GE Aviation, a world-leading provider of jet engines, has integrated IoT solutions into its engine manufacturing plant in Durham, North Carolina, to enhance production reliability and reduce downtime.

Implementation and Outcomes:

GE Aviation deployed IoT sensors across its production lines to monitor equipment health and performance in real time. AI and machine learning algorithms are used to examine the data in order to forecast probable equipment breakdowns and improve maintenance plans. This deployment has resulted in a 30% decrease in unscheduled downtime and a 20% boost in overall production efficiency.

Expert Insight:

GE Aviation CEO David Joyce explained, saying, "We have gained unprecedented visibility into our equipment performance through the integration of IoT into our manufacturing operations." Our ability to increase output and decrease downtime has been greatly aided by IoT-powered predictive maintenance.

Durham's plant manager, Lisa Smith, stated, "IoT has revolutionized the way we manage our maintenance activities." Our downtime has been greatly decreased by being able to anticipate equipment breakdowns before they happen, which has helped us stick to a regular production schedule and fulfill delivery obligations.

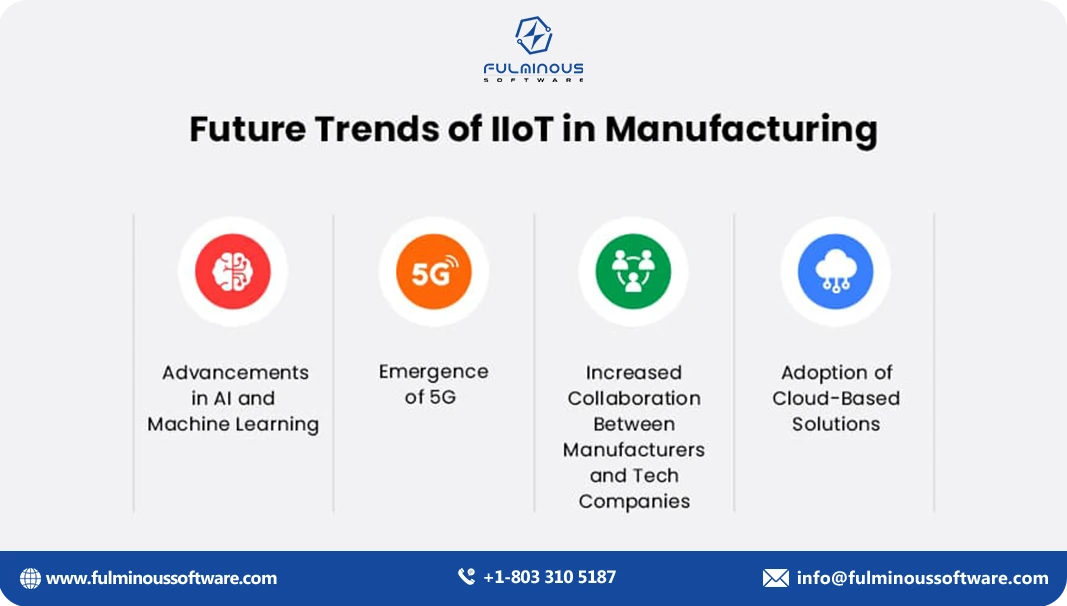

Future Trends in IoT and Manufacturing

The future of IoT in manufacturing is far beyond our expectations. Emerging trends such as 5G, edge computing, and advanced analytics are poised to further reduce equipment downtime and enhance operational efficiency.

5G Connectivity

Improved Data Transfer and Communication: 5G technology promises much faster data transfer speeds, lower latency, and more dependable connections than previous wireless technologies. For manufacturing, this means that IoT devices can exchange data and communicate in real-time with minimal delay. increased communication capabilities will enable more accurate and timely monitoring of equipment conditions, facilitating faster responses to potential issues.

Impact on Predictive Maintenance: 5G will allow manufacturers to deploy more sensors and connect more devices seamlessly, creating a dense network of IoT devices. This increased connectivity allows for the collection of vast amounts of data, which can be analyzed to predict equipment failures more accurately.

Edge Computing

Real-Time Data Processing: Processing data nearer to the point of generation is known as edge computing, as opposed to depending on centralized cloud servers. This facilitates real-time data processing and decision-making. Edge computing makes it possible to instantly analyze data from IoT sensors in a production setting, which speeds up the process of identifying possible problems.

Enhanced Reliability and Security: Edge computing also improves manufacturing operations' security and dependability by processing data locally. Because sensitive data does not have to travel to distant servers, there is less chance of a data breach and timely decision-making. Reducing downtime and preserving continuous operations depend heavily on this targeted processing capacity.

Advanced Analytics

Machine Learning and AI Integration: Advanced analytics, powered by machine learning (ML) and artificial intelligence (AI), are transforming how data is utilized in manufacturing. Machine learning (ML) and artificial intelligence (AI) technologies can analyze vast amounts of data from IoT sensors to identify patterns and anomalies that human operators might miss.

Prescriptive Maintenance: Beyond predictive maintenance, advanced analytics enable prescriptive maintenance, which not only predicts when a failure might occur but also suggests the best course of action to prevent it. By recommending specific maintenance actions, such as adjusting machine settings or replacing certain components, prescriptive maintenance minimizes downtime and extends the lifespan of equipment.

Integration of Digital Twins

Virtual Replicas for Optimization: Digital twins are virtual replicas of physical assets, systems, or processes that are used to simulate and analyze real-world conditions. In manufacturing, digital twins allow for the real-time monitoring and simulation of equipment performance. Digital twins can predict failures and optimize maintenance schedules.

Enhanced Decision-Making: The use of digital twins enables manufacturers to run simulations to understand the impact of different maintenance strategies without affecting actual production. This enhances decision-making.

Conclusion

The maintenance of factory production, profitability, and customer satisfaction depend heavily on minimizing equipment downtime. This problem can be drastically solved with the incorporation of IoT technologies. With the help of IoT, predictive maintenance may anticipate machine problems before they happen, greatly reducing unscheduled downtime. Manufacturers can minimize unplanned breakdowns and increase equipment longevity by scheduling maintenance proactively using real-time data from sensors monitoring parameters like temperature, vibration, and pressure.

IoT also improves operational efficiency by improving real-time monitoring and control. Rapid alerts and diagnostics made possible by remote monitoring make it possible to react quickly. By acting quickly, this intervention reduces downtime and guarantees continuous production flow. IoT enhances inventory management by reducing stockouts and overstocking through automatic reordering and real-time tracking. Furthermore, early defect detection through continuous monitoring results in quicker remedial action and higher product standards. The capacity of IoT to track energy usage lowers expenses and has a positive environmental impact by identifying waste and optimizing use. By keeping an eye on the surrounding environment and sending out notifications in case of danger, it also improves worker safety.

The limitless advantages of IoT in minimizing downtime are demonstrated by real-world examples from Siemens, Harley-Davidson, Bosch, and GE Aviation. Future developments in digital twins, edge computing, and 5G connectivity will improve predictive maintenance and real-time data processing even more, maximizing manufacturing efficiency.

Adopting IoT in manufacturing offers reduced downtime, increased productivity, improved quality control, enhanced energy management, and better safety compliance. Integrating IoT solutions is crucial for staying competitive and ensuring operational excellence in an increasingly digital world.

Are you ready to reduce equipment downtime and boost productivity in your factory? Explore how IoT solutions can change things for your manufacturing business. Don't miss out on this golden opportunity to modernize your manufacturing process. Connect to our experts to learn more about IoT applications tailored to your industry and discover how we can help you implement these trending technologies. Take the first step towards a smarter, more efficient manufacturing factory today!

Frequently Asked Questions (FAQs)

Q1: What is equipment downtime?

A: Equipment downtime refers to periods when machinery or equipment in a factory is not operational, leading to a halt in production.

Q2: Why is reducing equipment downtime important?

A: Reducing equipment downtime is important because it helps maintain continuous production, increases productivity, minimizes revenue loss, and improves overall operational efficiency.

Q3: What are the common causes of equipment downtime?

A: Common causes include:

- Unexpected breakdowns

- Lack of regular maintenance

- Communication issues

- Poor inventory management

- Human errors

- Power problems

- Environmental conditions

- Cybersecurity threats

- Inadequate training

- Data management issues

Q4: How can the Internet of Things (IoT) help reduce equipment downtime?

A: IoT can reduce equipment downtime by:

- Providing real-time monitoring of equipment

- Enabling predictive maintenance

- Enhancing inventory management

- Improving quality control

- Optimizing energy usage

- Enhancing safety and compliance

Q5: What is predictive maintenance, and how does it differ from traditional maintenance?

A: Predictive maintenance uses IoT sensors and data analytics to predict when equipment is likely to fail, allowing maintenance to be performed just in time to prevent unexpected breakdowns. Traditional maintenance is usually scheduled at regular intervals or performed reactively after a breakdown.

Q6: How can I start implementing IoT solutions in my factory?

A: Start by:

- Assessing your needs and identifying pain points

- Researching and choosing suitable IoT sensors and platforms

- Running a pilot project to test the solutions

- Analyzing data to optimize processes

- Scaling up the implementation based on pilot success

Q7: What are the benefits of implementing IoT for inventory management?

A: IoT improves inventory management by:

- Tracking inventory levels in real-time

- Automating the reordering process

- Enhancing supply chain visibility

- Reducing delays through better logistics and resource planning

Q8: What future trends in IoT are expected to further reduce equipment downtime?

A: Future trends include:

- 5G connectivity for faster data transfer

- Edge computing for real-time data processing

- Advanced analytics and AI for improved predictive maintenance

- Integration of digital twins for simulation and optimization

HIRE A TOP SOFTWARE DEVELOPMENT COMPANY

Verified

Expert in Software & Web App Engineering

Verified

Expert in Software & Web App Engineering

I am Manish Kumawat, co-founder of Fulminous Software, a top leading customized software design and development company with a global presence in the USA, Australia, UK, and Europe. Over the last 10+ years, I am designing and developing web applications, e-commerce online stores, and software solutions custom tailored according to business industries needs. Being an experienced entrepreneur and research professional my main vision is to enlighten business owners, and worldwide audiences to provide in-depth IT sector knowledge with latest IT trends to grow businesses online.

Partner with Top-Notch Web Application Development Company!

Discuss your Custom Application Requirements on info@fulminoussoftware.com or call us on +1-903 488 7170.

15 Days Risk-Free TrialRecommended Articles