Innovative Ways to Stay Competitive in the Manufacturing Industry

Manish Kumawat

Last Updated on: 07 October 2025

When you look around, you see strong competition in every industry. From healthcare to manufacturing industries, businesses are seeking ways to be the best in this competition. Especially, when you look at the manufacturing industry, businesses are spending thousands of dollars to stay competitive. Because the manufacturing industry is one of the constantly evolving industries.

It's all about staying competitive, don’t settle for one-time success! Yes! This competition is not a 100m race. Instead, it is a marathon. So you need well-planned long-term strategies to be on the front line of this competition. When you learn from those who stay top in the manufacturing industry, you can see how they are preparing always to maintain competitiveness. The manufacturing world is a jungle out there. If you're not constantly evolving, you risk getting eaten alive by the competition. So, let's take a look at some important strategies that can help your manufacturing business to stay competitive.

Understanding the Competition in the Manufacturing Industry

Before getting into the strategies for staying competitive, let's have a look at real statistics of the current competition in the manufacturing industry.

- By 2028, the smart manufacturing market is projected to have grown from US$ 249.628 billion in 2022 to US$ 365.22 billion. (source)

- By 2024, there will be 5.46 million businesses operating in the manufacturing sector. (source)

- In the Manufacturing market, the enterprise density is expected to reach 705 by 2024. (source)

- Among manufacturers, 83% predict that in the next five years, smart factories will change the way they produce goods. (source)

- 700,000+ manufacturing enterprises operate in the United States only. (source)

- The manufacturing industry's worldwide big data market is expected to grow to USD 21.51 billion by 2032. (source)

Seeing all these, how can we ignore the relevance of staying competitive in the manufacturing business?

Remember! Change and Staying Updated is the Key to Staying Competitive

If you ask what to do to stay competitive in the manufacturing industry, we can say that willingness and enthusiasm to change and eagerness to stay updated is the first thing to do.

A resistance to change is common in most business owners. But this may be a hindrance to the growth of your business. When you consider successful manufacturing businesses, you can see how they are enthusiastic to adapt to change according to the needs of the time. If you want success, be ready to accept new ideas. Don't be afraid to try new things. Experiment with different technologies, processes, and strategies.

At the same time, you need an eagerness to learn the latest things and stay updated. Stay informed about current events and developments in your field. Attend conferences, read trade journals, and build professional networks. Always be ready to change your plans as circumstances demand. You can succeed if you stay aware of emerging trends and adjust accordingly.

Remember, change isn't always easy, but it's necessary for survival. So we will discuss more tips for this in the coming section!

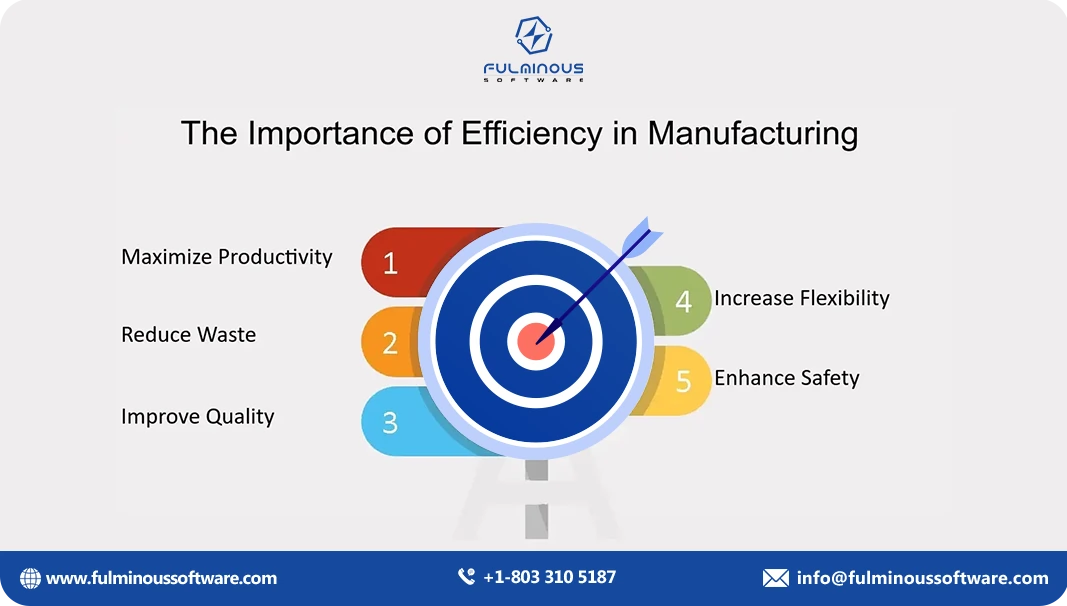

Why Maintaining Competitiveness in the Manufacturing Industry is Important

In the manufacturing world, it's a constant battle to stay ahead. Companies that can adapt to changes and do things better than their competitors are the ones that thrive. Here's why:

- Growth and Profit: By attracting more customers and improving efficiency, competitive businesses can grow and make more money.

- Customer Satisfaction: Understanding and meeting customer needs is essential for building a loyal customer base.

- Resilience: Competitive companies are better prepared to handle challenges like economic downturns or technological disruptions.

- Talent Attraction: A strong reputation for competitiveness attracts top talent, which can drive innovation and growth.

- Efficiency and Cost Reduction: By optimizing processes and reducing waste, competitive businesses can improve profitability.

- Differentiation: Standing out in a crowded market requires offering unique products or services that meet customer needs better than competitors.

- Innovation: Continuous improvement and innovation are key to staying competitive and seizing new opportunities.

- Customer Loyalty: Providing excellent products, fair prices, and timely delivery builds customer trust and loyalty.

- Global Reach: Competitiveness allows businesses to compete on a global scale, expanding their markets and customer base.

- Long-Term Success: By staying competitive, companies can ensure their long-term survival and success in the dynamic manufacturing industry.

Role of Trending Technologies in the Manufacturing Industry Competitiveness

Technology is the one major driving force to stay competitive. As technologies are changing and updating day by day, their role in staying competitive is unmatchable.

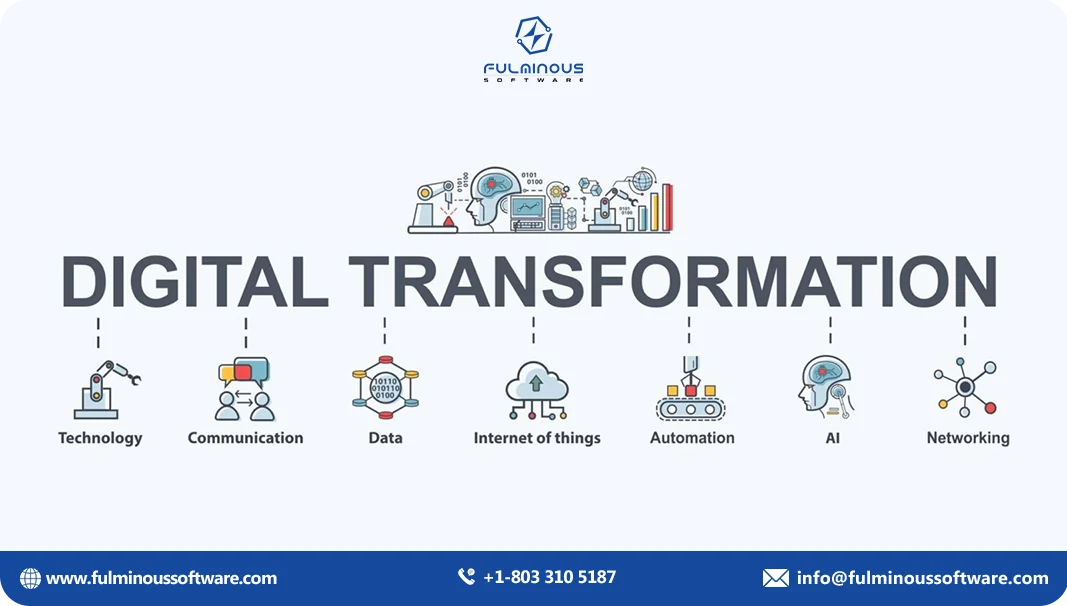

Let’s see about a key term “Digital Transformation”

For successfully staying competitive in the manufacturing industry overall transformation is vital which includes Digital Transformation, Business Model Transformation, Organizational Transformation, Technological Transformation, and Sustainability Transformation. Digital transformation is one of the important transformations on the list. Digital transformation is all about integrating trending and useful technologies into the business mainly in the manufacturing process.

Remember when restaurants were all about paper menus and waitstaff taking orders? Now, many restaurants have gone digital. Customers can order and pay directly from their phones, often using QR codes. Some restaurants even have robot waiters! In the same way, you can digitalize your manufacturing business and get plenty of benefits.

For manufacturing businesses, digital transformation is about using technology to improve how they operate. It's not just about having a website; it's about using that website to connect with customers, sell products, and gather data. Digital transformation is like upgrading your manufacturing business to a new one. It's about staying relevant in a world that's moving at lightning speed.

The first step is to get a feature-rich manufacturing website

Before getting more into other technologies, your manufacturing business needs an attractive and feature-rich website. If you do not have it, then build a new one. If you have an outdated one, then re-design it. In both cases, you need assistance from a manufacturing website development company like Fulminous Software

When your manufacturing has a superb website, it can work as your brochure, marketing tool, and online store. People can easily access you, see what you are making, and communicate with you easily. The more benefits are: showcases products and services, builds trust and credibility, improves search engine rankings, generates leads, provides customer support, and enhances brand awareness.

Other trending technologies and how it is useful for manufacturing business

Here's a look at some of the key trends shaping the manufacturing landscape:

- Artificial Intelligence (AI) and Machine Learning

- Predictive Maintenance: AI algorithms can analyze machine data to predict failures, reducing downtime and maintenance costs.

- Quality Control: AI-powered vision systems can inspect products for defects with greater accuracy than human inspectors.

- Process Optimization: AI can optimize manufacturing processes, identifying inefficiencies and suggesting improvements.

- Internet of Things (IoT)

- Connected Machines: Devices with IoT capabilities can gather and exchange data, offering operational insights in real-time.

- Smart Factories: IIoT can create interconnected systems that enable autonomous decision-making and optimize resource allocation.

- Supply Chain Visibility: IoT can track products and materials throughout the supply chain, improving transparency and efficiency.

- Robotics and Automation

- Collaborative Robots (Cobots): Cobots automate jobs and boost efficiency by collaborating with human workers.

- Autonomous Mobile Robots (AMRs): AMRs can transport materials and products throughout the factory floor without human intervention.

- Automation of Repetitive Tasks: Robots can automate repetitive and dangerous tasks, reducing the risk of injuries and improving worker safety.

- 3D Printing

- Rapid Prototyping: 3D printing allows for quick creation of prototypes, reducing development time and costs.

- Custom Manufacturing: 3D printing can produce highly customized products, meeting specific customer needs.

- On-Demand Production: 3D printing can enable on-demand manufacturing, reducing inventory costs and lead times.

- Cloud Computing

- Scalability: Cloud computing provides flexible resources that can be scaled up or down as needed.

- Data Storage: Cloud-based storage solutions can store large amounts of manufacturing data securely and efficiently.

- Collaboration: Cloud-based tools can facilitate collaboration between teams and partners.

- Augmented and Virtual Reality (AR/VR)

- Training and Simulation: AR/VR can provide immersive training experiences for workers, improving skills and safety.

- Remote Assistance: AR/VR can enable remote experts to assist technicians on the factory floor.

- Design Visualization: AR/VR can help visualize product designs and identify potential issues before manufacturing begins.

- Blockchain

- Supply Chain Transparency: Blockchain can provide a transparent and immutable record of product movement and provenance.

- Anti-Counterfeiting: Blockchain can help prevent counterfeit products from entering the market.

- Smart Contracts: Smart contracts built on the blockchain can streamline operations and cut down on paperwork.

- Cybersecurity

- Data Protection: Cybersecurity measures are essential to protect sensitive manufacturing data from cyber threats.

- Network Security: Secure networks are crucial for preventing unauthorized access to manufacturing systems.

- Incident Response: Manufacturing companies need to have plans in place to respond to cyberattacks effectively.

12 Tips to Stay Competitive in the Manufacturing Industry

Are you fed up with trying several things to stay competitive in the manufacturing business? Are you searching for a long-term strategy to stay competitive in the manufacturing industry? We will discuss 12 secret tips to stay competitive in the manufacturing industry.

- Embrace Technology and Automation

Multi-dimensional benefits including fast production, maximum efficiency, cost reduction, and many more are the result of adapting trending technologies and automation. Overall growth is 100% guaranteed when you go with technologies and automation.

- Leverage Modern Tools: Utilize the latest technology and machinery to streamline operations, reduce costs, and enhance product quality.

- Automate Repetitive Tasks: Employ robots and automated systems to handle routine tasks efficiently, saving time and minimizing errors.

- Harness IoT: Connect machines and devices to enable seamless communication and automated problem-solving.

- Utilize AI: Employ artificial intelligence to analyze data, identify trends, and optimize production processes.

- Invest in Employee Development

Another area you need to take care of is employee development. When you train and empower employees, their overall productivity will be boosted.

- Provide Skill Training: Equip your workforce with the necessary skills to operate new equipment and software, boosting their confidence and productivity.

- Foster Versatility: Train employees in various tasks to create a flexible team capable of adapting to changing demands.

- Nurture Leadership: Develop your experienced employees into leaders to motivate teams and improve overall performance.

- Prioritize Sustainability

As a social entity, it is important to prioritize sustainability. Even though it is your responsibility, meanwhile your reputation will also increase.

- Reduce Waste: Minimize waste in materials, water, and energy consumption to reduce costs and environmental impact.

- Recycle and Reuse: Implement recycling programs and explore opportunities for reusing materials to save money and contribute to a greener planet.

- Invest in Energy Efficiency: Upgrade to energy-saving equipment and consider renewable energy sources to reduce your carbon footprint.

- Optimize Supply Chain Management

Improving your manufacturing supply chain management can lead to faster delivery times and lower production costs.

- Build Strong Relationships: Cultivate strong partnerships with reliable suppliers to ensure timely delivery of high-quality materials.

- Manage Inventory Effectively: Maintain accurate inventory levels to avoid shortages or excess stock, which can lead to wasted resources.

- Diversify Suppliers: Don't rely solely on a single supplier to mitigate risks and protect your business from disruptions.

- Enhance Product Quality

Customers always prefer the quality of products. Focusing on better product quality in manufacturing helps ensure customer satisfaction and strengthens your brand reputation.

- Implement Quality Control: Establish rigorous quality control systems to identify and address defects early in the production process.

- Listen to Customer Feedback: Pay close attention to customer feedback to identify areas for improvement and enhance product quality.

- Continuously Improve: Regularly review and refine your processes to drive ongoing improvements in quality and efficiency.

- Adapt to Market Trends

Staying updated with market trends in manufacturing enables your business to quickly respond to shifting demands and industry changes.

- Stay Informed: Keep abreast of industry trends, competitor activities, and customer needs to make informed decisions and seize opportunities.

- Maintain Flexibility: Be prepared to adjust production based on market demand to meet customer expectations and capitalize on emerging trends.

- Diversify Product Offerings: Offer a variety of products to cater to different customer segments and mitigate risks associated with market fluctuations.

- Deliver Exceptional Customer Service

Providing outstanding customer service 24/7 in manufacturing builds loyalty and sets your business apart from competitors.

- Respond Promptly: Address customer inquiries and issues promptly to demonstrate your commitment to customer satisfaction.

- Provide After-Sales Support: Offer comprehensive support after the sale, such as installation assistance, maintenance guidance, and troubleshooting.

- Build Strong Relationships: Foster strong relationships with customers through personalized interactions and exceptional service.

- Foster Innovation

Manufacturing innovation can result in game-changing solutions that keep your company ahead of the curve.

- Encourage Employee Ideas: Create a culture that values employee input and encourages them to share their innovative ideas.

- Invest in Research and Development: Allocate resources to research and development to explore new materials, processes, and product features.

- Collaborate with Others: Partner with universities, tech companies, or research institutions to access new knowledge and resources.

- Leverage Data Analytics

Making better judgments, increasing production efficiency, and cutting waste are all made possible by the use of data analytics in manufacturing.

- Track and Analyze Data: Collect and analyze data on production speed, machine performance, and product quality to identify areas for improvement.

- Utilize Predictive Maintenance: Employ data analytics to predict maintenance needs and prevent unexpected equipment breakdowns.

- Gain Customer Insights: Analyze customer data to understand market trends, improve products, and tailor marketing strategies.

- Build Strategic Partnerships

When you join hands with the right ones, it is guaranteed that you are moving toward success. Developing strategic alliances in the manufacturing industry might improve your prospects and expand your skills.

- Collaborate with Suppliers: To ensure fair terms, prompt deliveries, and creative solutions, collaborate closely with suppliers.

- Network with Industry Peers: Join industry associations and participate in networking events to share knowledge and explore collaboration opportunities.

- Partner with Technology Providers: Collaborate with technology companies like Fulminous Software to integrate advanced solutions into your operations.

- Prioritize Health and Safety

Ensuring health and safety in your manufacturing operations protects employees and boosts overall productivity.

- Provide Safety Training: Ensure that employees are adequately trained on safety procedures and equipment usage.

- Identify and Address Hazards: Conduct regular safety inspections to identify and address potential hazards in the workplace.

- Foster a Safety Culture: Create a workplace culture where safety is a top priority and employees feel empowered to report hazards and concerns.

- Maintain a Customer-Centric Approach

Adopting a customer-centric strategy in manufacturing helps align your products and services with what your clients truly need.

- Gather Customer Feedback: Regularly seek feedback from customers to understand their needs and preferences.

- Offer Customized Solutions: Tailor your products or services to meet specific customer requirements.

- Prioritize Transparent Communication: Keep customers informed about product updates, delivery timelines, and any issues to build trust and loyalty.

Collaborate with Tech Heroes and Stay Competitive

If you are confused with the complex terms mentioned above, it is better to collaborate with a top tech company. If you hire a top-class tech partner like Fulminous Software, you can stay tension-free and focus on other manufacturing activities.

At the same time, we can guarantee long-term assistance. If you choose a non-reputed company, they may provide you with competitiveness for a short time. But as we mentioned earlier, it's a long-term journey. It is more difficult to stay competitive than to achieve competitiveness once.

As Fulminous Software is renowned for its commitment to maintaining long-term relationships with businesses, you can ensure life-long competitiveness. Our skilled professionals are dedicated to continuous learning about technologies, you will get the most recent solutions in the market.

Conclusion

It takes more than just short-term efforts to remain competitive in the manufacturing sector. Prioritizing consumer needs, adopting new technologies, and keeping up with trends all require constant attention. Businesses that are proactive in putting new ideas into practice will stay ahead of the curve as the industry changes quickly.

Prioritize developing solid relationships with partners and customers in addition to your staff if you want to ensure long-term business success. You can maintain your business flexible and ready for future difficulties by committing to continuous learning and improvement.

Your operations should be centered around digital transformation, automation, and data-driven decision-making. Latest technologies like IIoT, AI, ML, and so on can be a breakthrough in your business success.

Remember, maintaining competitiveness is a marathon, not a sprint. Consistent growth comes from steady and strategic planning.

Get in touch with Fulminous Software right now if you require professional advice on utilizing technology for your manufacturing company to keep ahead of the competition.

FAQs

- Q1. Why is staying competitive crucial in manufacturing?

- A: Staying competitive ensures growth, customer satisfaction, and resilience against challenges. It also helps attract talent, reduce costs, and maintain long-term success.

- Q2. How can technology enhance manufacturing competitiveness?

- A: Technology improves efficiency, product quality, and decision-making. AI, IoT, automation, and data analytics optimize processes, reduce downtime, and boost innovation.

- Q3. What role does sustainability play in competitiveness?

- A: Sustainability reduces waste, energy costs, and environmental impact. It improves brand recognition and helps companies meet global sustainability targets.

- Q4. How does IoT benefit manufacturing businesses?

-

- Real-time data monitoring and insights

- Improved supply chain visibility and efficiency

- Enhanced predictive maintenance to reduce downtime

- Q5. What’s the importance of supply chain optimization?

- A: Optimizing the supply chain reduces delays, improves inventory management, and lowers costs, ensuring smoother operations and better customer satisfaction.

- Q6. What are the key advantages of automation in manufacturing?

-

- Increased production speed and consistency

- Reduced human errors and safety risks

- Cost savings through optimized operations

- Q7. How can AI improve manufacturing efficiency?

- A: AI optimizes production by predicting maintenance needs, enhancing quality control, and analyzing data to refine processes, reducing errors and costs.

- Q8. How can data analytics improve manufacturing processes?

-

- Informed decision-making based on real-time data

- Identification of inefficiencies and bottlenecks

- Improved product quality and customer satisfaction

- Q9. How can digital transformation boost competitiveness?

- A: Digital transformation integrates modern tech, streamlines operations, and enhances customer engagement. It’s key to staying relevant in a rapidly evolving industry.

- Q10. Why is employee development essential in manufacturing?

- A: Investing in employee training boosts skills, productivity, and adaptability. Skilled employees drive innovation, operational efficiency, and overall business growth.

HIRE A TOP SOFTWARE DEVELOPMENT COMPANY

Verified

Expert in Software & Web App Engineering

Verified

Expert in Software & Web App Engineering

I am Manish Kumawat, co-founder of Fulminous Software, a top leading customized software design and development company with a global presence in the USA, Australia, UK, and Europe. Over the last 10+ years, I am designing and developing web applications, e-commerce online stores, and software solutions custom tailored according to business industries needs. Being an experienced entrepreneur and research professional my main vision is to enlighten business owners, and worldwide audiences to provide in-depth IT sector knowledge with latest IT trends to grow businesses online

Partner with Top-Notch Web Application Development Company!

Discuss your Custom Application Requirements on info@fulminoussoftware.com or call us on +1-903 488 7170.

15 Days Risk-Free Trial