How Digital Technology Drives Industry 4.0

Manish Kumawat

Last Updated on: 29 September 2025

When we closely watch the changes brought by digital technologies in the industrial sector, you will be amazed. Before 20 years ago, none would have imagined or believed the amazing things that trending technologies like IoT, ML, and AI are doing today.

Just consider how machines give us accurate manufacturing data, predict possible failures, and maximize production efficiency with the help of the latest technologies. Let’s admit the fact that those manufacturers are the wise ones who adapted the trending technologies at the right time and in the right way.

The reality is that, if you are a business owner, you need to continuously monitor the pulse of the industry to which you belong and act wisely. Especially in the manufacturing sector, the transformation of the industry from the use of steam engines in the 18th century to Industry 4.0 in today’s scenario.

Here we will discuss the way digital technologies lead Industry 4.0, what is going on in this sector currently, and what is coming next. This guide will be a well-defined set of information that helps you in making maximum benefits in this Industry 4.

Why Manufacturers Must Know about Industry 4.0 and its Technologies?

Are you aware of Digital transformation, Industry 4.0, Industrial IoT, AI, >Manufacturing automation, and so on? A deep knowledge of what is happening in the sector we belong is the real driving force for your manufacturing business to reach the peak of success.

In simple words, if a manufacturer is not aware of or ignores Industry 4.0 and its technologies, his business may fail to cope with other businesses. If you are still carrying out your manufacturing business process fully manual in this advanced era of automation and technologies, no doubt this is the stumbling block for your success journey.

Today, most manufacturing companies are eagerly seeking ways to adapt these trending technologies and to be a part of Industry 4.0. Just consider the leaders in your industry, you will notice that those businesses are continuously updating their manufacturing processes with the latest technologies.

Beyond Knowing: Adapting Is Essential

Let’s see the other side of the coin. Beyond the knowledge of Industry 4.0 and its Technologies, you need the willingness to integrate suitable technologies into your manufacturing process.

As a business owner, you may have many questions like – is it necessary? Which one do I have to adapt? How much does it cost? Is it profitable? Who will help me? Don’t get confused, we have answers to all your questions.

Even though there are many challenges in adapting these technologies, a leading digital transformation service provider like Fulminous Software can do this task for you. But at the same time, you need courage to experiment and patience to see its benefits.

The reality is that the more you get the knowledge about these technologies and their benefits, as a manufacturing business owner you will be inspired to integrate them into your business.

What Is Industry 4.0?

Industry 4.0 is like a new level in the game of technology and manufacturing. Just like there are game upgrades with new features, Industry 4.0 is the latest upgrade for industries (like factories or companies). Here manufacturers use smart and latest technology to make things faster, safer, and more efficient.

Industry 4.0 uses special digital technologies like the Internet of Things (IoT), Artificial Intelligence (AI), robots, and data analytics. It makes machines “talk” to each other, learn from each other, and work together in a smarter way.

Why Is It Called “Industry 4.0”?

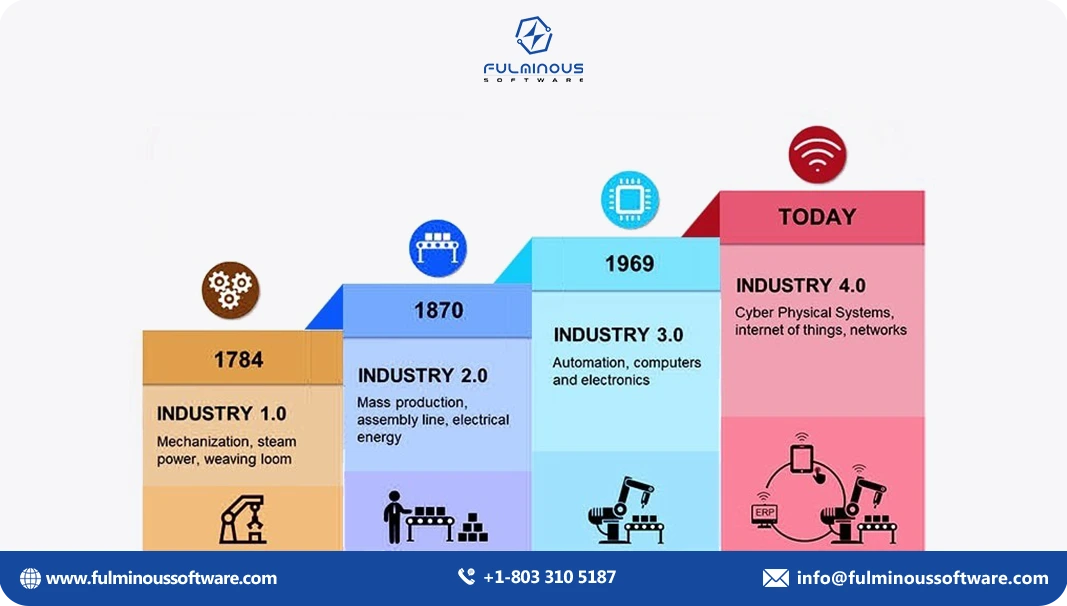

Before we had Industry 4.0, there were three other “levels” or “revolutions” in the industry:

- Industry 1.0 – This was when people first used steam and water power to run machines in factories.

- Industry 2.0 – Then came electricity and assembly lines, which made it possible to make things faster.

- Industry 3.0 – Computers and automation started to help us make things even faster and more accurate.

- Industry 4.0 – Now, Industry 4.0 is a big leap forward where we use digital technology, automation, and smart machines that can communicate and make decisions with little help from people.

Key 6 Technologies That Drive Industry 4.0

In Industry 4.0, certain digital technologies are like the “tools” that make everything work better. Let’s see the major technologies in Industry 4.0:

1. Internet of Things (IoT)

Even if we use the term IoT in general, it can be clearly called Industrial IoT. One of the key technologies that advances the entire production process is industrial IoT. In factories, IoT helps machines “talk” to each other by connecting them through the internet.

Machines can share information, like how much work they’ve done or if they need repairs. If you want to keep an accurate track of everything happening in factories, IIoT is the key. See the benefits:

- Improved Production Speed: Machines talk to each other, making work faster.

- Prevents Sudden Breakdowns: Machines are alert when they need fixing. Fixing them early means fewer surprises and no sudden stops in production.

- Live Performance Tracking: Factory managers can see how machines work in real time, helping them fix problems instantly to save time.

- Cuts Costs: IoT helps save money by using less power and reducing waste.

- Better Product Quality: Machines check for problems during production, ensuring products meet higher quality standards.

- Better Product Quality: Machines check for problems during production, ensuring products are top quality before reaching customers, reducing complaints.

- Safer Workplace: Sensors detect dangers like overheating.

- Better Inventory Tracking: Managers know how much material is available.

- Flexible Manufacturing: Machines can quickly change tasks, helping factories switch products easily, and meeting different customer demands quickly.

- Less Human Work Needed: Machines handle repetitive tasks, freeing workers to focus on more important jobs that need human skills.

- Quick Problem Solving: Machines share information, helping managers quickly find and fix problems without needing much time.

- Faster Decisions: IIoT provides instant data, making it easier for managers to decide what needs to be done right away.

- Helps Meet Customer Needs: Real-time updates help factories keep up with orders, so customers get products faster and on time.

- Predicts Maintenance Needs: Machines tell managers before they need repairs, saving money by fixing issues early and preventing big repairs.

- Easier Process Management: IIoT makes it easier to monitor every production step, helping keep everything running smoothly and organized.

- Better Worker Productivity: With IIoT doing repetitive jobs, workers can focus on creative tasks, making work more interesting and productive.

- Increases Profit: By cutting costs and improving quality, IIoT helps factories make more profit and grow their business.

2. Artificial Intelligence (AI)

As Artificial Intelligence has become more familiar nowadays there is no surprise about what AI can do for manufacturing businesses. AI is like a super-smart helper who learns by watching what happens around it. In Industry 4.0, AI helps machines make decisions on their own.

For example, if a machine notices that a part is about to break, it can signal that it needs fixing before it completely stops working. AI can also help produce quality stuff. By checking for mistakes or defects in products, AI makes sure that only the best items are shipped to customers.

- Predictive Maintenance: AI helps machines know when they might break, so they can be fixed before stopping and causing big problems.

- Improved Quality Control: AI checks products for mistakes or defects, making sure only the best items are sent to customers every time.

- Automation of Decision-Making: AI helps machines make smart choices on their own, like fixing problems quickly without waiting for a person to decide.

- Increased Efficiency and Productivity: AI does boring tasks fast, so people can focus on more important work, making everything go faster and smoother.

- Cost Savings: AI helps prevent problems before they happen, saving money by avoiding repairs, waste, and bad products that cost extra.

- Enhanced Customization and Flexibility: AI can understand what people like, helping companies make products that fit what customers want more quickly and easily.

- Data-Driven Insights: AI looks at lots of data to find useful patterns, helping businesses make better choices about how to improve.

3. Robots

You may feel the amazing way robotics advances the manufacturing process inside factories. Robots are like workers that don’t need rest. Because of their ability to work around the clock, they can produce goods more quickly and precisely.

Some manufacturers run their factories 24*7 and some run 24*7 when demand for their products increases. In those times, this technology is the most suitable solution.

In Industry 4.0, robots don’t just do simple tasks; they can also work together with people. They can manage challenging activities and even update better over time by learning from them. Do not think that this technology may cause unemployment. Because they can work along with humans.

- Non-Stop Work: Robots can work all day and night without getting tired, helping make products faster and without needing breaks.

- Increased Speed and Accuracy: Robots do their tasks quickly and carefully, helping to make things more quickly and with fewer mistakes.

- Working with People: Robots can work side by side with people, helping them with tasks while still learning from the work they do.

- Handling Tough Jobs: Robots can do hard or dangerous jobs that are too difficult for humans, keeping workers safe and doing the job well.

- Continuous Learning: Robots can learn from their tasks, getting better and faster over time, so they can work even more efficiently.

4. Big Data and Analytics

The name itself reveals Big Data means a huge amount of information. If you are a manufacturing business owner, there is no need to describe the importance of manufacturing data.

In Industry 4.0, companies collect data from machines, people, and sensors with this technology. Such accurate data tells everything about what's going on in the factory. Just like a weather forecast machine, Data analytics is the process of analyzing. The analyzed data can help you find ways to make production faster or identify problems before they happen.

- Fixing Problems Faster: If something goes wrong, Big Data helps find out why quickly, so it can be fixed before it gets worse.

- Improving Production Speed: By studying the data, companies can figure out how to make products faster.

- Preventing Problems Before They Happen: Big Data helps predict problems before they happen, so machines can be fixed before they break down completely.

- Making Smarter Decisions: Data tells companies what works best, so they can make better choices, like how to improve quality or speed up work.

- Tracking Progress Easily: Companies can see how well things are going by checking the data, making it easy to know if improvements are needed.

- Better Planning for the Future: By analyzing past data, companies can make smart plans for the future, knowing what worked and what can be improved.

5. Cloud Computing

The reality is that there is no replacement for cloud computing solutions. Cloud computing is like a big storage space in the sky (not literally, but you get the idea). It lets manufacturing companies save all their data in one place that they can access from anywhere.

Cloud computing also makes it easier to store data without needing big, expensive servers on-site, and it’s safer because the data can be backed up automatically. No doubt, these features of cloud computing are vital in Industry 4.0.

- Access From Anywhere: Cloud computing lets companies store data in one place, so workers can access it from anywhere, even at home.

- Easy Information Sharing: Cloud helps companies share data quickly, so people can work together without being in the same place or office.

- No Need for Big Servers: Instead of expensive servers, cloud computing stores data online, saving money and space for companies and making work easier.

- Automatic Backups: Cloud computing keeps data safe by automatically making backups, so if something goes wrong, companies won’t lose important information.

- Increased Flexibility: Since data is in the cloud, workers can use it in different devices, making it easy to work anytime, anywhere.

- Security and Safety: Cloud services keep data protected with special security, making it safer than keeping information on a personal computer.

- Cost Savings: Cloud computing helps companies save money because they don’t need to buy and maintain expensive equipment to store their data.

6. Cybersecurity

When you closely watch the digital realm, you can see the rapid increase in number of cyber attacks. When cyber attacks are using various advanced technologies, you need to be more updated than them. The cyber-attacks may affect the reputation of manufacturing businesses.

Cybersecurity is like a shield for your manufacturing business’s digital information. Industry 4.0 companies invest in cybersecurity to make sure their data and systems are secure. Invest wisely in these advanced cybersecurity technologies and save your data, reputation, and money.

- Protecting Information: Cybersecurity acts like a shield, keeping important data safe from hackers and making sure no one can steal it.

- Preventing Attacks: It stops bad people from breaking into systems and causing problems, like stealing money or ruining important work.

- Building Trust: When companies protect their data, customers trust them more, knowing their information is safe and won’t be misused.

- Stopping Bad Software: Cybersecurity blocks harmful programs (like viruses) from getting into computers, which could mess up systems or steal information.

- Safe Online Work: It lets workers use computers and the internet safely, so they can do their jobs without worrying about online dangers.

- Keeping Systems Running Smoothly: Cybersecurity helps companies avoid big problems by stopping attacks that could make systems crash or stop working properly.

How These Technologies Work Together in Industry 4.0

As mentioned earlier, each technology has its own role in Industry 4.0. The reality is that you can’t ignore anyone’s technology. When you place them properly in the right position, your manufacturing business will work without failures. Each of the technologies above plays an important role:

- IoT connects all the machines and sends real-time data.

- AI uses this data to make smart choices.

- Robots do tasks and learn as they go.

- Big Data and Analytics make sense of all the data to spot trends.

- Cloud Computing stores all the information safely.

- Cybersecurity protects the data from cyber threats.

Remember one thing: when you go to implement these technologies, you must approach a well-experienced and proficient digital transformation service provider. At the same time, they need expertise in all the above-mentioned technologies. Otherwise, you have to approach different agencies for each technology and it may cost a huge amount.

Examples of Industry 4.0 in Action

Here are a few examples of how different companies use Industry 4.0 technologies:

Automobile Manufacturers

Car factories use robots and IoT to automate assembly lines, ensuring cars are built quickly and safely with high quality.

Company Example: Tesla’s factories utilize advanced robots and IoT sensors to streamline the car manufacturing process.

Food Manufacturers

In food production, sensors monitor for contamination, defects, or temperature changes to ensure only safe and high-quality food reaches consumers.

Company Example: Nestlé uses sensors throughout its food manufacturing processes to check for potential contamination and ensure the quality and safety of every product, meeting strict food safety standards.

Healthcare Device Manufacturers

Sensors and IoT devices are used to collect real-time data from medical devices, improving monitoring and patient outcomes.

Company Example: Philips Healthcare uses IoT-connected medical devices that monitor patient health data in real time.

Medicine Manufacturers

AI and data analytics are used in drug manufacturing to optimize production processes, track inventory, and ensure product quality.

Company Example: Pfizer uses AI-driven analytics in its manufacturing facilities to improve drug production efficiency, track batches, and ensure the safety and effectiveness of medications.

Cosmetics Manufacturers

In cosmetics, smart sensors and AI help monitor production quality, personalize products, and optimize formulations based on customer data.

Company Example: L'Oréal leverages AI and machine learning in their production process to create personalized skincare solutions and optimize product formulations to match customer needs and preferences.

Electronic Device Manufacturers

Robots and automated systems are used to assemble complex electronic products quickly, ensuring high precision and minimizing defects.

Company Example: Samsung uses robotics and IoT in its manufacturing plants to automate the assembly of smartphones and other electronics, improving speed, precision, and quality control.

Dress Manufacturers

In the fashion industry, smart machines and AI are used to predict trends, automate cutting and stitching, and personalize garments for consumers.

Company Example: Adidas uses 3D printing and AI-powered design software to create custom, high-performance footwear and apparel while optimizing production for speed and efficiency.

The Future of Industry 4.0: Industry 5.0?

The changes that are brought by these technologies may take your thoughts toward the emergence of Industry 5.0. One thing is clear: Industry 4.0 is still evolving. In the future, we can expect more advanced robots, smarter AI, and even faster data analytics.

- Self-Healing Machines: Machines that can fix themselves if something breaks.

- Hyper-Connected Factories: Even more machines will be connected, creating a fully automated “smart” factory.

- More Customization: Factories will make products even faster and more customized for each customer’s needs.

As technology grows, Industry 4.0 will bring new possibilities and make factories more efficient, safe, and productive. But, if you want to be the leader in the manufacturing industry, you need to be updated continuously and change accordingly.

Conclusion

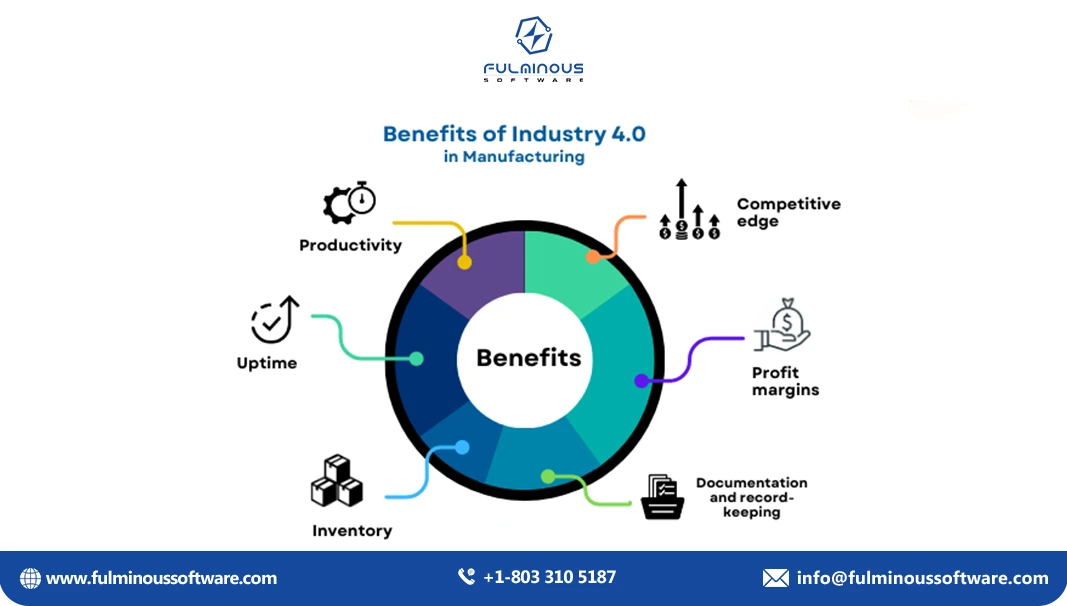

You have seen the leading technologies that have been taking manufacturing to the peak of advancement. If you are a manufacturing business owner who searches the way to grab maximum benefits, why should wait more?

Have you noticed the leading manufacturers in each sector like Adidas, Tesla, Nestle, and many others making use of these technologies and making a profit? Without a doubt, it can be stated that there are maximum benefits of Industry 4.0.

Always remember two things: choose the right technology and choose the right technology service providers. With this, you can be the leader in your sector. As mentioned earlier, this is the right time, so act wisely.

When you integrate these feature-rich profitable technologies you are taking your manufacturing business to the frontline Industry 4.0. Fulminous Software is a top-notch service provider of digital transformation and implementing all these advanced technologies. If you want to integrate these trending technologies and harvest plenty of profit, contact us.FAQs

- Q1. What is Industry 4.0?

- A: Industry 4.0 is using smart machines, robots, and data to make factories work faster, safer, and more efficiently.

- Q2. Why is Industry 4.0 important?

- A: It helps factories produce things faster, reduces waste, saves money, and improves the quality of products with less human effort.

- Q3. What is IoT (Internet of Things)?

- A: IoT connects machines to the internet so they can talk to each other, share information, and work better together.

- Q4. How does Artificial Intelligence (AI) help factories?

- A: AI helps machines make decisions, fix problems, and improve work speed by learning from data and past actions.

- Q5. What do robots do in Industry 4.0?

- A: Robots work non-stop to build products faster, more precisely, and help people with tough or dangerous tasks in factories.

- Q6. What is Big Data?

- A: Big Data means collecting a lot of information from machines to find patterns, solve problems, and make smarter choices.

- Q7. What is cloud computing?

- A: Cloud computing stores data online, so companies can access it anywhere, anytime, without needing big, expensive computers on-site.

- Q8. How does cybersecurity protect factories?

- A: Cybersecurity protects factory data from hackers, keeping everything safe and ensuring the systems run smoothly without any problems.

- Q9. How do machines predict when they need repair?

- A: Machines use sensors and data to notice small problems before they become big, preventing sudden breakdowns and costly repairs.

- Q10. Will robots replace human workers?

- A: No, robots help with repetitive tasks, while humans focus on creative or decision-making work, making work easier and safer.

HIRE A TOP SOFTWARE DEVELOPMENT COMPANY

Verified

Expert in Software & Web App Engineering

Verified

Expert in Software & Web App Engineering

I am Manish Kumawat, co-founder of Fulminous Software, a top leading customized software design and development company with a global presence in the USA, Australia, UK, and Europe. Over the last 10+ years, I am designing and developing web applications, e-commerce online stores, and software solutions custom tailored according to business industries needs. Being an experienced entrepreneur and research professional my main vision is to enlighten business owners, and worldwide audiences to provide in-depth IT sector knowledge with latest IT trends to grow businesses online.

Partner with Top-Notch Web Application Development Company!

Discuss your Custom Application Requirements on info@fulminoussoftware.com or call us on +1-903 488 7170.

15 Days Risk-Free TrialRecommended Articles